FLEXIBLE

GOALS

FAST UPDATES

&

SCENARIOS

EASY

SETUP

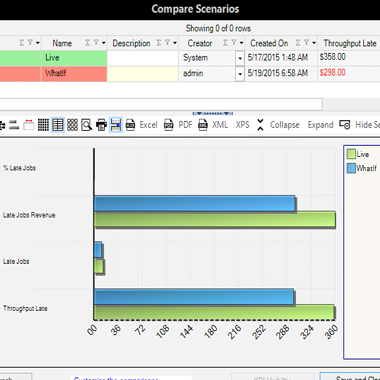

As the needs of your business change you can easily redirect how your production and inventory resources are allocated to meet those needs.

Deliver to your customers faster and more reliably by turning up the focus on lead time reduction and on-time delivery.

Dial-in higher overall equipment and labor effectiveness for maximum productivity and efficiency.

Focused on cash flow, reducing costs, increasing top-line revenue? Simply choose your measures to meet the demands of your current business environment.

Your PlanetTogether Optimization Engine will create great solutions quickly for your entire planning and scheduling team. Powered by the right tools you'll see an amazing transition from reactive to proactive.

No more chaos in scheduling. Your resources will be allocated based on agreed upon rules, policies, and objectives.

Take full advantage of the flexibility of your people and equipment to produce more output with existing resources.

Efficiently buy, make, and move material to reduce raw, Work-In-Process and finished inventory. Your warehouses and shop floor may start to look spacious.

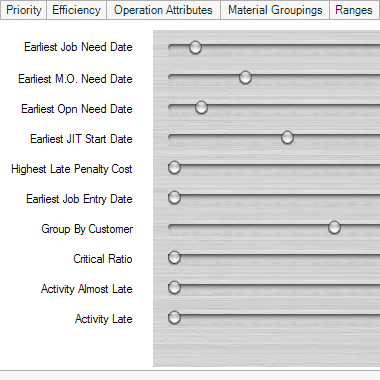

Predicting the impacts of your business decisions often requires looking at your data in a new way. Create alternate scenarios quickly and then look at the optimized result based on the possible future reality. The picture will paint itself.

Evaluate the results of any optimization with clear comparison of Key Performance Indicators. Turn on CoPilot to optimize specific KPI automatically.

Sometimes the details really matter. In that case, the Impact Analysis is your best friend. It explains how individual jobs were affected by the optimization.

Share the knowledge with co-workers by creating optimized scenarios for others to review.

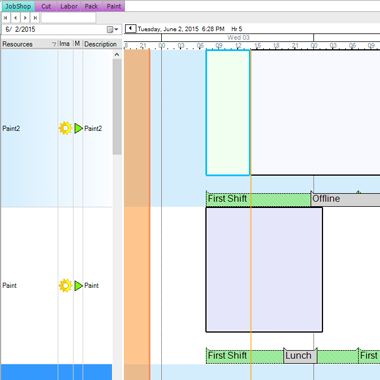

Like adjusting the equalizer on a stereo, simply slide left or right to set the relative weight of each optimization factor.

Choose a Key Performance Indicator and let CoPilot create scenarios for you to find plans that target your measure.

Automatically schedule new jobs to maximize your KPI without causing any existing jobs to be late.

See the result of optimizations side-by-side to understand the trade-offs and make the best decision.

Fully automate your optimization and other processes.

Make and buy as late as possible (taking buffers into account) to minimize inventory and flow times.

Build in time buffers for materials, bottlenecks, and shipping to maximize your business throughput.

Take advantage of flexibility in your resources and processes to achive optimized results.

Specify preferences on how products are assigned to resources to optimize output and quality.

Benefit from powerful optimization while still preserving your manual changes.

"Shipment to promise dates improved by 8 percent and production output levels increased 16 percent."

GARY BISHOP

"We feed it the facts we know, and it automatically proposes an optimized schedule that allows us to meet those dates. It’s something we tried, but never could do manually."

DICK MARX

"PlanetTogether frees Joyce from all the mechanics. We run more efficiently, with more money to the bottom line. From an executive point of view, that’s one result that gives me a chance to relax and enjoy another cup of coffee."

DANA KING

"PlanetTogether's what-if scenarios and KPIs allow you to quickly adjust to changing demands coming from the C-level of your organization."

DEAN DIETRICH