Topics: capacity planning, machine learning, production scheduling, Inventory Management, Efficiency, Supply Chain Optimization, Optimization, PlanetTogether Software, Supply Chain Planning

Manufacturing facilities often rely on efficient supply chain planning to meet their production targets and customer demands. The use of machine learning in supply chain planning has become increasingly popular in recent years, thanks to its ability to automate decision-making and optimize operations. Supply chain planning is an integral part of any manufacturing facility. Efficient planning can reduce lead times, optimize operations, and improve customer satisfaction. With the increasing amount of data available today, machine learning has become a valuable tool in supply chain planning. PlanetTogether is a software that utilizes machine learning algorithms to help manufacturing facilities optimize their supply chain planning. In this blog post, we will discuss how PlanetTogether can help manufacturing facilities achieve efficiency and customer satisfaction through optimized supply chain planning.

What is Supply Chain Planning?

Supply chain planning involves the coordination of all activities involved in the movement of goods from the raw material stage to the finished product stage. It includes the planning and scheduling of production, procurement of raw materials, management of inventory, and the logistics of transporting finished goods. The goal of supply chain planning is to optimize the flow of goods and minimize costs while meeting customer demand.

What is Machine Learning?

Machine learning is a subset of artificial intelligence that enables computers to learn from data without being explicitly programmed. It involves the use of algorithms that can automatically identify patterns and insights in data. Machine learning algorithms can be used to automate decision-making processes and optimize operations.

The Role of Machine Learning in Supply Chain Planning

Machine learning is a subset of artificial intelligence that enables computers to learn and improve from experience without being explicitly programmed. When applied to supply chain planning, machine learning algorithms can analyze large datasets to identify patterns and insights that can help organizations make better decisions.

One of the main benefits of using machine learning in supply chain planning is its ability to automate decision-making processes. For example, machine learning algorithms can predict demand and suggest the optimal production schedule based on current inventory levels and production capacity. This can help organizations reduce lead times, minimize inventory costs, and increase production efficiency.

Another benefit of using machine learning in supply chain planning is its ability to optimize operations in real-time. For example, if a supplier is experiencing delays or disruptions, machine learning algorithms can quickly adjust production schedules to avoid delays and ensure that customer orders are fulfilled on time. This can help organizations improve customer satisfaction and reduce the risk of lost sales.

How PlanetTogether Can Help Optimize Supply Chain Planning

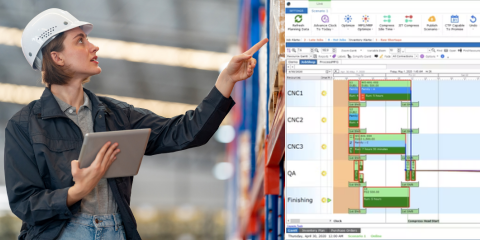

PlanetTogether is a software that utilizes machine learning algorithms to help manufacturing facilities optimize their supply chain planning. It provides a comprehensive set of features that can help organizations achieve efficiency and customer satisfaction. The software can help organizations improve their supply chain planning by providing the following features:

PlanetTogether can help manufacturing facilities optimize their production schedules by taking into account factors such as machine availability, labor availability, and order priority. The software can also use machine learning algorithms to predict demand and suggest the optimal production schedule based on current inventory levels and production capacity.

PlanetTogether can help manufacturing facilities optimize their capacity planning by providing real-time visibility into their production capacity. The software can also use machine learning algorithms to predict future capacity requirements and suggest changes to the production schedule to meet demand.

PlanetTogether can help manufacturing facilities optimize their inventory management by providing real-time visibility into inventory levels and suggesting optimal reorder points. The software can also use machine learning algorithms to predict demand and suggest changes to inventory levels to avoid stockouts and overstocking.

PlanetTogether can help manufacturing facilities optimize their supply chain by providing real-time visibility into supplier performance and suggesting changes to the production schedule to avoid delays and disruptions. The software can also use machine learning algorithms to predict future supply chain issues and suggest changes to the production schedule to mitigate risks.

Machine learning is playing an increasingly important role in supply chain planning, and manufacturing facilities can benefit greatly from its use. By utilizing machine learning algorithms, organizations can automate decision-making processes, optimize operations in real-time, and reduce lead times and inventory costs. PlanetTogether is a comprehensive supply chain planning software that utilizes machine learning algorithms to help manufacturing facilities optimize their operations. The software can help organizations improve their production scheduling, capacity planning, inventory management, and supply chain optimization, leading to increased efficiency and improved customer satisfaction.

Topics: capacity planning, machine learning, production scheduling, Inventory Management, Efficiency, Supply Chain Optimization, Optimization, PlanetTogether Software, Supply Chain Planning

0 Comments

No video selected

Select a video type in the sidebar.

LEAVE A COMMENT