Answer in 60 Seconds:

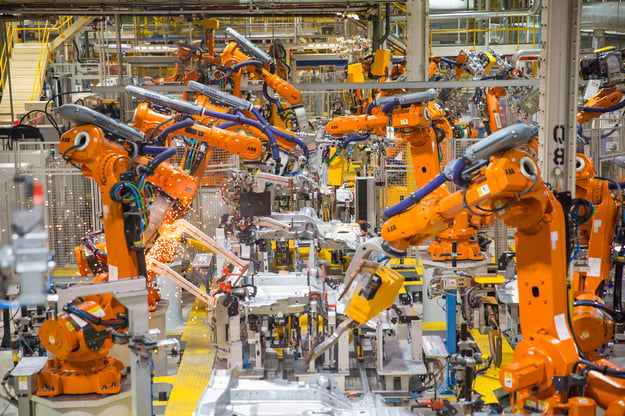

Operations management keeps manufacturing on time and on budget by coordinating people, materials, and equipment. Benefits include higher throughput, better resource use, and clearer accountability; downsides include cross-team dependency and human error. If you face frequent rescheduling, bottlenecks, or delivery misses, pairing ERP/MRP data with APS can align demand, capacity, and schedules in real time.Operations management is a term used to describe the processes concerned with planning, organizing, and supervising the overall production process.

This process was initially developed to help facilities improve the collaboration between various processes of the organization. Operations management is usually delivery-focused, which means that the facility will use these processes to ensure that production is carried out in the most efficient manner possible to deliver its goods on time.

There are 2 key terms that help define Operations Management: Supply Chain Management and Logistics. With a firm basis in these areas, Operations Management ensures that resources are utilized carefully by reducing waste and implementing cost-effective decision making strategies.

As Operations Management has become key to manufacturing operations around the globe, it is important to understand the advantages and disadvantages of the process.

Key Advantages of Operations Management for Production Teams

Overall, operations management is a key factor for manufacturing organizations that wish to take their production to the next level. Some notable advantages include:

- Profitability Management: When your operations are properly managed, it is easier for your company’s executives to rely on the production activity to get a better understanding of your revenue stream. They are then able to rely on that consistent information to find new ways to increase sales or come up with new product ideas.

- Better Resource Management: Operations management processes focus on effectively managing all of your resources to ensure that their potential is being maximized. Resources can include physical machines as well as labor resources.

- Competitive Advantage: Being able to coordinate the multiple levels and components of your manufacturing organization means that things will run much more smoothly. Your production time will likely decrease, allowing you to deliver goods on time which is a crucial aspect of having great customer relations. This will allow you to promptly deliver great products and keep you ahead of the competition.

Where Operations Management Breaks Down Most Often

With any process, it is important to consider the disadvantages that can occur:

- Multi-Level Dependency: One of the main disadvantages is that a large amount of the success of implementing operations management procedures requires coordination between the different components of the organization. Even if an effective plan is put in place, it will fail if it is not carried out in the proper manner by all components.

- Human Error: Another prevalent problem within manufacturing operations is the fact that humans tend to be mistake-prone. Most of the time, this issue occurs during the transition from manufacturing to sale. Because of this, it is important to ensure that operations management is coordinating various areas effectively such as operations, marketing, finances, accounting, engineering, information, and human resources.

Overall, if the individual components within the organization are not working well together, there will only be a limited amount of success emerging from operations management processes. A software that is becoming extremely common among manufacturing operations is advanced planning and scheduling software. This software can provide thorough insight into the various components of the production operations. APS

We’re able to make strategic decisions that improve operations. We can proactively prepare for anticipated increases or slowdowns in demand.

DICK MARX, MATERIALS MANAGER, KNAPHEIDE TRUCK EQUIPMENT

How APS Software Strengthens Operations Management

When operations management breaks down, it’s rarely due to a single issue—it’s usually the handoff points: planning to production, scheduling to execution, and ERP/MRP data to real-world constraints. APS is built for that gap. By integrating ERP/MRP plans with finite-capacity constraints—labor, machines, materials, changeovers, and maintenance windows—PlanetTogether APS helps teams turn “best-effort schedules” into schedules production can actually run.

With PlanetTogether APS, teams can:

- Build feasible finite-capacity schedules aligned to labor, machines, materials, and changeovers

- Incorporate operational feedback (status updates, constraints, maintenance windows, priorities) and re-optimize quickly

- Reduce schedule churn by communicating changes clearly across planning and operations

- Protect bottlenecks, improve on-time delivery, and reduce firefighting without relying on spreadsheets

- Run what-if scenarios that support faster operational decision-making

Watch the video below to see how APS + operations integration improves production scheduling. Then download the Manufacturing Planning Profitability Infographic for a fast, visual breakdown of where spreadsheet planning quietly drains margin.

Integrating APS with Operations to Improve Production Scheduling

When operations management breaks down, it’s rarely due to a single issue—it’s usually the handoff points: planning to production, scheduling to execution, and ERP/MRP data to real-world constraints. This video shows how tighter collaboration between operations teams and planning functions reduces delays, improves responsiveness, and turns “best-effort schedules” into schedules production can actually run.

You’ll see how advanced planning and scheduling (APS) supports finite capacity scheduling by aligning labor, machines, materials, and changeovers to what’s truly available. For production planners, schedulers, operations managers, and plant leadership, the focus is on practical ways to reduce schedule churn, improve on-time delivery, and keep bottlenecks from dictating performance.

The video also connects the dots between ERP/MRP and operational execution—how integrating operational feedback (status updates, constraints, maintenance windows, and priorities) helps planning teams make better decisions faster. With PlanetTogether APS, teams can update schedules quickly, communicate changes clearly, and run scenarios that support operational decision-making—without relying on error-prone spreadsheets.

Download the Manufacturing Planning Profitability Infographic

Most operations teams don’t lose margin because they “plan poorly”—they lose it because planning is forced to happen in spreadsheets, disconnected from real capacity, changeovers, and day-to-day execution. That gap creates late deliveries, reactive overtime, excess inventory, and expensive last-minute fixes.

Our downloadable infographic outlines where manual planning systems quietly drain profitability—and why manufacturers that improve planning and scheduling fundamentals create a measurable advantage in delivery performance and throughput. It’s a fast, visual resource for operations leaders and planners who need a clear case for modernizing how schedules are built, updated, and communicated.

What you’ll take away from the infographic:

- Common ways manual planning leads to lost sales from late deliveries/long lead times

- How poor sequencing drives capacity loss due to changeovers and cleanouts

- Why reactive schedules trigger overtime costs during bottleneck periods

- How uncoordinated maintenance planning can reduce output and hurt service levels

- Where planning inefficiency increases inventory carrying cost and expedited shipping

Operations Management FAQs

-

What is operations management in manufacturing?

Operations management is how a manufacturer plans, coordinates, and controls the people, processes, and equipment that turn materials into finished goods. It spans scheduling, quality, inventory flow, and day-to-day execution.

-

What are the biggest advantages of operations management?

The biggest advantages are improved throughput, better use of labor and equipment, more predictable delivery performance, and clearer accountability across teams.

-

What are common disadvantages or risks of operations management?

The most common risks are cross-department dependency (one breakdown disrupts everything), process complexity, and human error during handoffs. These risks usually show up as rework, missed dates, or firefighting.

-

How do you reduce human error and coordination breakdowns?

Standardize workflows, define ownership for key decisions (priority changes, schedule releases, material readiness), and use shared KPIs. Then add tools that provide a single source of truth for schedules and constraints.

-

When does APS add value beyond ERP/MRP for operations management?

APS adds the most value when you need constraint-based scheduling, frequent replanning, and scenario modeling. If ERP/MRP outputs don’t reflect real capacity, changeovers, or labor constraints, APS typically closes that execution gap.

See how capacity-aware scheduling reduces firefighting—request a PlanetTogether APS demo.