Within manufacturing, developing a plan for your resources is absolutely vital for operation. Without proper resource planning for your manufacturing operation, you will have a challenging time managing various areas within your supply chain such as inventory, production, and output.

Utilization of a materials requirements planning (MRP) can efficiently manage materials within production, making it much easier for project managers to order and organize materials that are in need of being assembled. Through MRP, the need for materials planning is eliminated and the system is able to easily carry out an efficient strategy. MRP has become a must for manufacturing facilities that are in need of keeping up with a consistently growing demand. Before implementing an MRP system, it is important to understand the advantages and disadvantages of the utilizing the software. Therefore, here are the advantages and disadvantages of utilizing MRP systems.

Advantages and Disadvantages of Utilizing Material Requirements Planning (MRP) Systems

The advantages of materials requirements planning (MRP) include the following:

- Aids with maintaining minimum inventory levels

- If you have minimum inventory levels, materials planning will also reduce associated costs

- Material tracking becomes much easier and ensures that economic order quantity is achieved for all lot orders

- Material planning smooths out capacity utilization and allocates correct time to products as per demand forecast

The disadvantages of materials requirements planning (MRP) include the following:

- Material planning is entirely dependent on inputs it receives from other system departments. If input information is not correct than output for material planning will also be incorrect

- Material planning requires maintenance of robust database with all information pertaining inventory records, production schedule, etc, without which output again would be incorrect

- Material planning system requires proper training for end users, as to get maximum out of the system

- Material resource planning system requires substantial investment out of time and capital

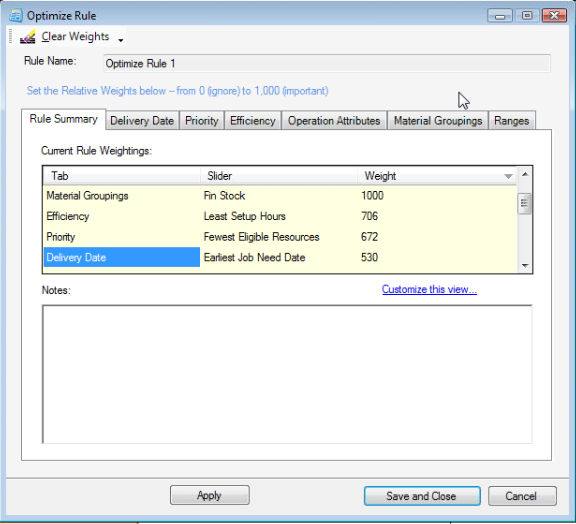

A software that can aid with materials requirements planning (MRP) is PlanetTogether’s Advanced Planning and Scheduling Software (APS). PlanetTogether’s Advanced Planning and Scheduling Software (APS) can aid with manufacturing operations around the globe that are in need of efficiency increase. PlanetTogether’s Advanced Planning and Scheduling Software (APS) allows manufacturers to easily view their production process as a whole and manipulate areas that are in need of aid. APS software can be implemented into operations around the globe.

Advanced Planning & Scheduling Software

Advanced Planning and Scheduling (APS) software has become a must for modern-day manufacturing operations due to customer demand for increased product mix and fast delivery combined with downward cost pressures. APS can be quickly integrated with a ERP/MRP software to fill gaps where these system lack planning and scheduling flexibility and accuracy. Advanced Planning and Scheduling (APS) helps planners save time while providing greater agility in updating ever-changing priorities, production schedules, and inventory plans.

Implementation of Advanced Planning and Scheduling (APS) software will take your manufacturing operations to the next level of production efficiency, taking advantage of the operational data you already have in your ERP.

Video: Lean Materials Planning – Minimizing Waste with APS

Lean manufacturing focuses on minimizing waste while delivering value to the customer, and effective materials planning is a critical part of that. In this video, you’ll see how PlanetTogether Advanced Planning & Scheduling (APS) supports lean materials management by turning your MRP outputs and ERP data into optimized, waste-reducing production plans.

You’ll learn how combining MRP with APS helps you:

- Maintain minimum inventory levels while meeting demand, reducing carrying costs tied to excess materials

- Smooth capacity utilization and allocate the right time to each product based on demand forecasts, instead of over- or under-loading resources

- Use APS to fill gaps where traditional MRP struggles (deterministic, infinite-capacity planning), adding realistic capacity and scheduling logic on top of your material plan

- Synchronize supply with demand to reduce inventories and avoid shortages, scrap, expediting, and other forms of lean waste

- Enable scenario-based, data-driven decision making, so planners can test options instead of relying on spreadsheets and tribal knowledge

This video is ideal for materials planners, production schedulers, and lean/CI teams who want to connect MRP, lean manufacturing, and APS to minimize waste across the entire materials planning process.

Make Materials Planning a Strategic Advantage, Not Just a System Setup

A materials requirements planning (MRP) system can efficiently manage materials, keep inventory at minimum levels, and smooth capacity utilization—but only if the data is accurate and the plan is translated into a realistic schedule. Without the right planning and scheduling layer, MRP can still produce incorrect or impossible plans and demand constant firefighting from planners.

Download our Material Requirements Planning (MRP) Infographic to see how you can:

- Understand the advantages and disadvantages of MRP so you know where it helps—and where it needs support

- Use MRP to maintain minimum inventory levels, achieve economic order quantities, and allocate capacity based on demand

- Recognize the limitations of traditional MRP (deterministic, infinite-capacity planning assumptions) and why advanced planning tools are required in practice

- Combine MRP with Advanced Planning & Scheduling (APS) to create optimized schedules, maximize bottleneck output, and synchronize supply with demand

- Leverage the operational data already in your ERP/MRP to take your manufacturing operation to the next level of production efficiency

Share it with your materials, planning, and operations teams as a concise visual guide to how MRP plus APS turns materials planning into a driver of lean, waste-reducing performance.