A constant challenge within manufacturing operations is to improve profit margins while maneuvering the unpredictable changes in supply and demand. Planners and schedulers must find the schedule that will optimally utilize resource capacity and meet your company's financial goals. Analytics can help you do just that.

So what are Production Planning & Scheduling Analytics?

For our purposes, Analytics can be defined as the discovery and interpretation of data. It focuses on knowing why things happened in the past and what will happen in the future to guide decision making.

If your production output is consistently lower than expected, analytics can help you identify the source of the problem. Is the issue contained to a single department? Are materials not arriving on time? Are certain machines not meeting their target production outputs? When the data is collected and interpreted, you can more easily find the right solution to fix the problem. This can include performing the required machine maintenance or purchasing your materials in advance so that they are available when you need them.

We're able to make strategic decisions that improve operations. We can proactively prepare for anticipated increases or slowdowns in demand.

DICK MARX, MATERIALS MANAGER, KNAPHEIDE TRUCK EQUIPMENT

Data is such an important aspect of business development as it guides business executives make the right decisions by monitoring the progress of production and measure the KPIs of interest against their targets.

Benefits of Production Planning & Scheduling Analytics

There are many benefits in analyzing and interpreting the data from your production plan and schedule. These include:

- Increased Visibility - Analytics plays an important part in increasing the visibility of the impact of the production schedule. Well-made analytics dashboards and reports should allow everyone in the company to understand how the current production plan and schedule are performing at the financial or operational level. This allows more people to bring in their expertise and suggest meaningful changes to the current scheduling process in the pursuit of continuous improvement.

- Align With Reality - Creating the most optimal production plan and schedule is a challenge. This is usually because most manufacturing facilities often have multiple scheduling constraints that must be accounted for during the creation of the schedule. Analytics allows you to compare the schedule plan to the actual production output to determine whether the schedule created is an accurate and feasible representation of what can actually be produced. Having a realistic and feasible plan will allow you to when items are to be completed.

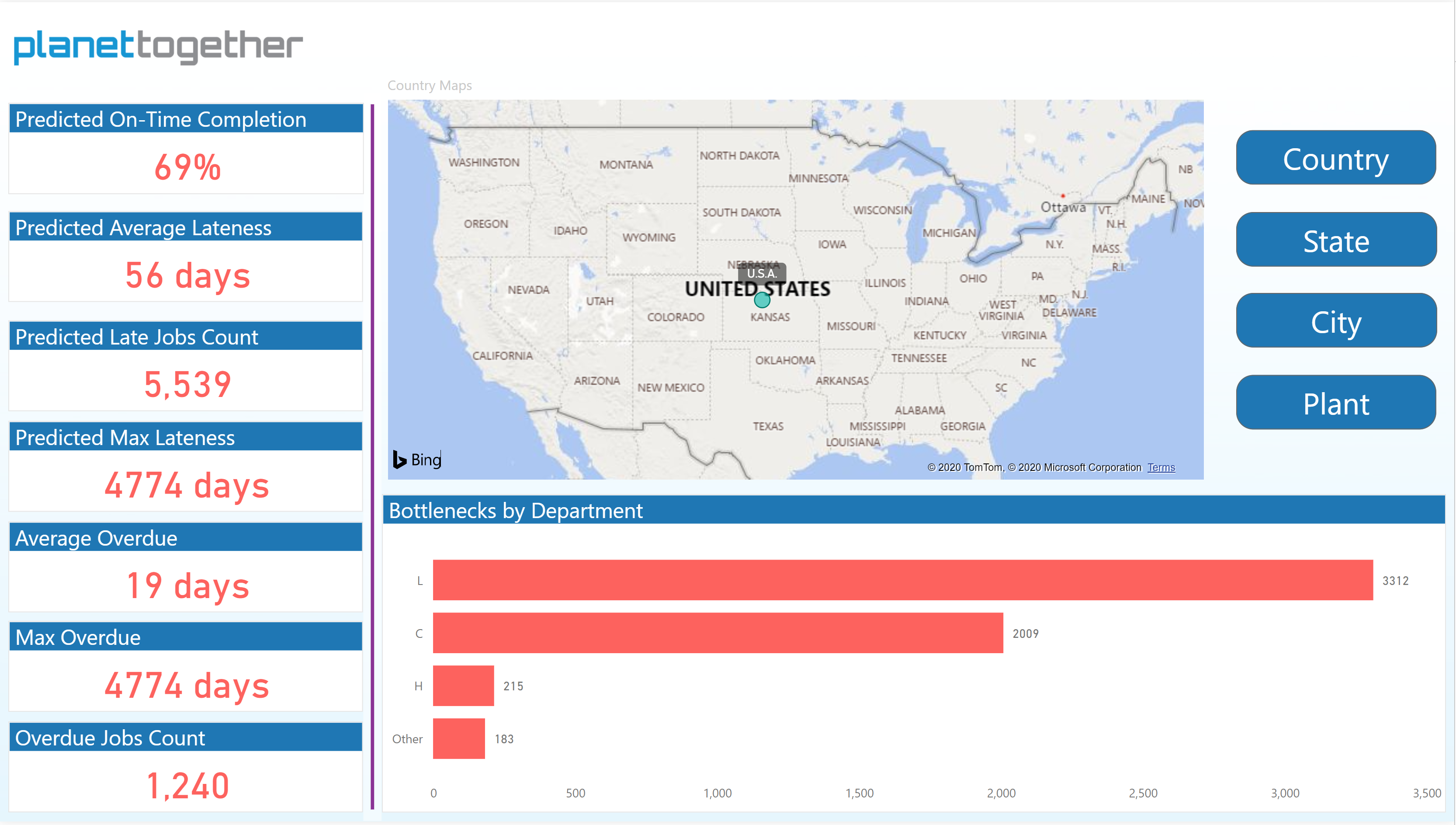

- Increase Agility - In recent years, agility has become the goal for many manufacturing facilities. This means being able to quickly adjust your production plan and schedule to meet varying changes in demand, unexpected disruptions, and other circumstances that life may throw your way. Being agile means making quick decisions and analytics can help by accurately predicting demand or by identifying underutilized resource capacity that could help your company meet a sudden surge in demand.

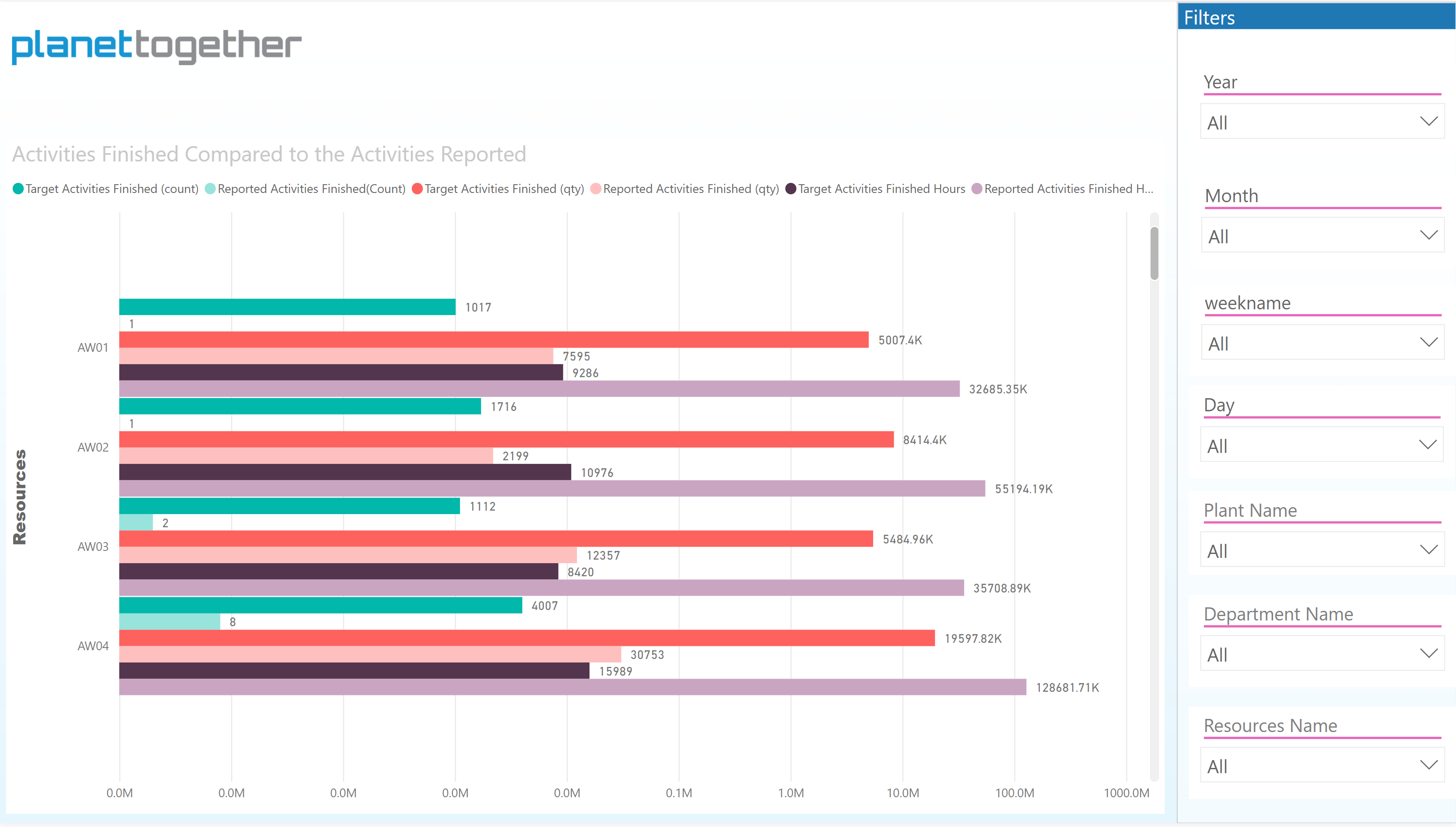

- Identify Bottlenecks - When your production output is consistently less than what you have predicted, you may be dealing with a capacity bottleneck. Reports that compare actual versus predicted work hours and quantities are a great way to identify areas or resources that are not meeting their expected targets. Further analysis into these areas will help you determine whether your machines are in need of replacement or whether your production schedule is not accurate nor realistic.

Production Planning & Scheduling Analytics with PlanetTogether

PlanetTogether Analytics with Power BI allows manufacturers to take full advantage of all of the information associated with their production schedule. Users are able to use up-to-data information to help them monitor the performance of the manufacturing process as well as improve any areas that are underperforming.

PlanetTogether Analytics reports are:

- Interactive - The reports allow you to drill-down to the underlying data as well as group and filter the data based on pre-defined categories. For example, looking at the planning report will allow you to see the capacity utilization of specific resources per product name.

- Future-Looking - Looking at the reports for the current schedule can allow you to better plan for future circumstances and identify which scheduling strategies and optimization rules are more beneficial than others.

- History Tracking - The PlanetTogether reports allow you to analyze the data based on previous as well as current schedules. In addition, you can see how changes to the production schedule impacted a customer's order and manage this appropriately.

Advanced Planning & Scheduling (APS) Software

Advanced Planning and Scheduling software has become a must for modern-day manufacturing operations as customer demand for increased product assortment, fast delivery, and downward cost pressures become prevalent. These systems help planners save time while providing greater agility in updating ever-changing priorities, production schedules, and inventory plans. APS Systems can be quickly integrated with an ERP/MRP software to fill the gaps where these systems lack planning and scheduling flexibility, accuracy, and efficiency.

With PlanetTogether APS you can:

The implementation of PlanetTogether's Advanced Planning and Scheduling (APS) software will take your manufacturing operations to the next level of production efficiency by taking advantage of the operational data you already possess in your ERP system. APS is a step in the right direction of efficiency and lean manufacturing production enhancement.

Video: Capacity Planning & Scheduling Analytics in PlanetTogether APS

Modern manufacturers need to improve margins while dealing with volatile demand, capacity constraints, and supply disruptions. Production planning & scheduling analytics turn raw data from your ERP and shop floor into insights that show why performance deviates from plan and what to change in your schedule, capacity plan, or forecast.

In this video, you’ll see how PlanetTogether APS with Analytics helps you:

- Use interactive dashboards to gain end-to-end visibility into capacity utilization, schedule adherence, and key KPIs across products, lines, and plants

- Compare planned vs. actual output so you can validate that your capacity plan and finite schedule are realistic—and correct them when they are not

- Improve demand forecasting and demand planning accuracy by analyzing historical patterns and how past schedules performed against forecast and customer orders

- Identify bottlenecks and under-utilized resources using analytics on work hours, quantities, and OEE, then adjust your schedule or capacity plan to maximize throughput

- Increase agility by pairing predictive/prescriptive analytics with APS what-if scenarios, so you can quickly re-plan when demand, supply, or constraints change

This video is ideal for planners, schedulers, and operations leaders who want to use capacity planning and scheduling analytics to make faster, data-driven decisions that improve service levels and profitability.

Turn Your Planning & Scheduling Analytics into Profit

Analytics give you more than attractive dashboards. When you track capacity utilization, plan vs. actual, demand patterns, and bottleneck performance, you can finally see which schedules work, which do not, and why. This lets you move from reactive firefighting to proactive capacity planning and finite scheduling aligned with reality.

Download our “The Money Is in the Planning” infographic to see how combining production planning & scheduling analytics with PlanetTogether APS helps you:

- Use analytics to create realistic, optimized schedules that balance efficiency and on-time delivery

- Spot capacity bottlenecks and under-utilized resources early, then adjust shifts, routings, or investments where they matter most

- Improve demand forecasting accuracy by tying forecast performance back to actual schedules and inventory outcomes

- Increase agility by pairing dashboards with APS what-if scenarios, so you can test new rules or priorities before committing to them

- Turn the operational data already in your ERP/MRP into a continuous improvement engine instead of static reports

Share it with your planning, scheduling, and operations teams as a concise visual guide to where analytics-driven capacity planning and APS deliver measurable business impact.