A scheduler once told me something during an explanation of their operations that stuck: The reactor listens to no one. It finishes when it finishes.

No drama. No warning. It just finishes. And when it does, the rest of the plant has to be ready. If not, everything begins to deviate. One tank fills too soon, one line runs too slow, and suddenly your Thursday looks like a puzzle dumped on the floor.

I've listened to teams explain this scene unfold more times than I care to admit. And each time, the scheduler carries the weight of timing, capacity, chemistry, and customer promise. All at once. All day. They don't really have days off. They panic about any vacation days they want to take.

The story below is one I have seen in many forms. It is a composite of real chemical operations - a few quiet frustrations drawn from conversations with customers across the industry. If you schedule chemical production, you will likely recognize pieces of your own week inside it.

The Batch That Arrives at the Wrong Moment

It starts with a reactor finishing a 45,000 pound batch late Thursday afternoon. A little earlier than forecasted. No one is surprised. Chemistry likes to keep its own schedule.

The scheduler checks the batch clock and askes herself:

Where is it going next?

Tank 14, at least on paper. Space available. Status clear. All signs point to yes.

Yet the tank farm supervisor answers with a flat tone:

Tank 14 is full.

And I have seen schedulers wince at that line like it carried a sting. Because it means plans they trusted were already slipping. It means some quiet variable changed behind the scenes. And it means someone now has to explain how a tank that looked empty at 8 am became full by 3.

This kind of thing happens for reasons that never travel alone. Yield variation. Slower filling performance. A workover batch pushed in at the last minute. Three sources, one outcome, and not a hint of it visible to the scheduler until too late. When schedulers say they feel like they can't trust their schedule, this is usually the moment they mean.

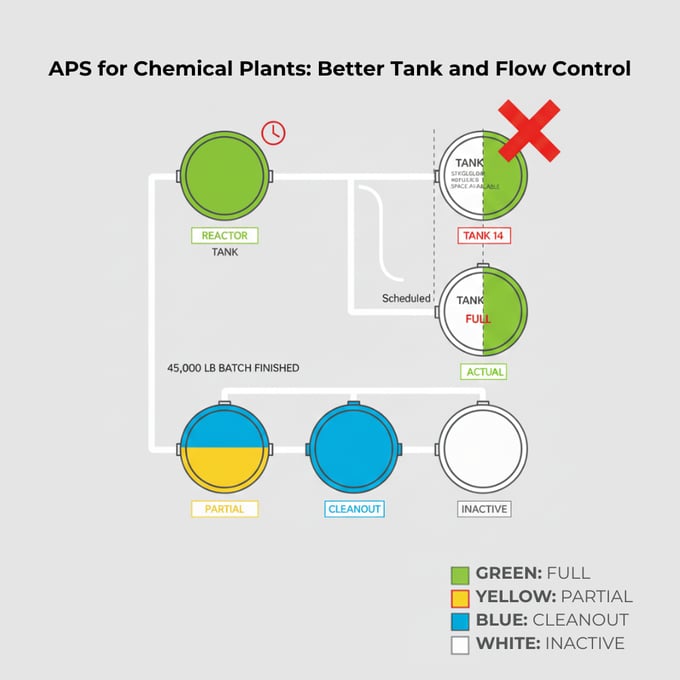

PlanetTogether’s 12.3.0 release shifts this entire dynamic. Storage is no longer an afterthought. It becomes a real, modeled part of the scheduling experience.

Storage Areas now represent tanks and silos and staging zones with rules the system respects.

Storage Connectors define flow limits, transfer behavior, and simultaneous connection constraints.

Instead of asking the tank farm for a status check, the system already knows the situation. Instead of hoping a spreadsheet formula caught the latest update, the schedule itself understands what the tank understands.

Visibility becomes the first fix. Now we can begin to work on predictable process improvements.

The Storage Problem Beneath the Storage Problem

The scheduler now scans for alternatives. Tank 7 has partial space. Tank 6 might work if operations slows the transfer rate. Tank 9 is empty but in a cleanout that no one wants to rush. You can almost feel the tension between decisions. Move too fast and you create a new conflict. Move too slow and the reactor waits.

And reactors do not like to wait.

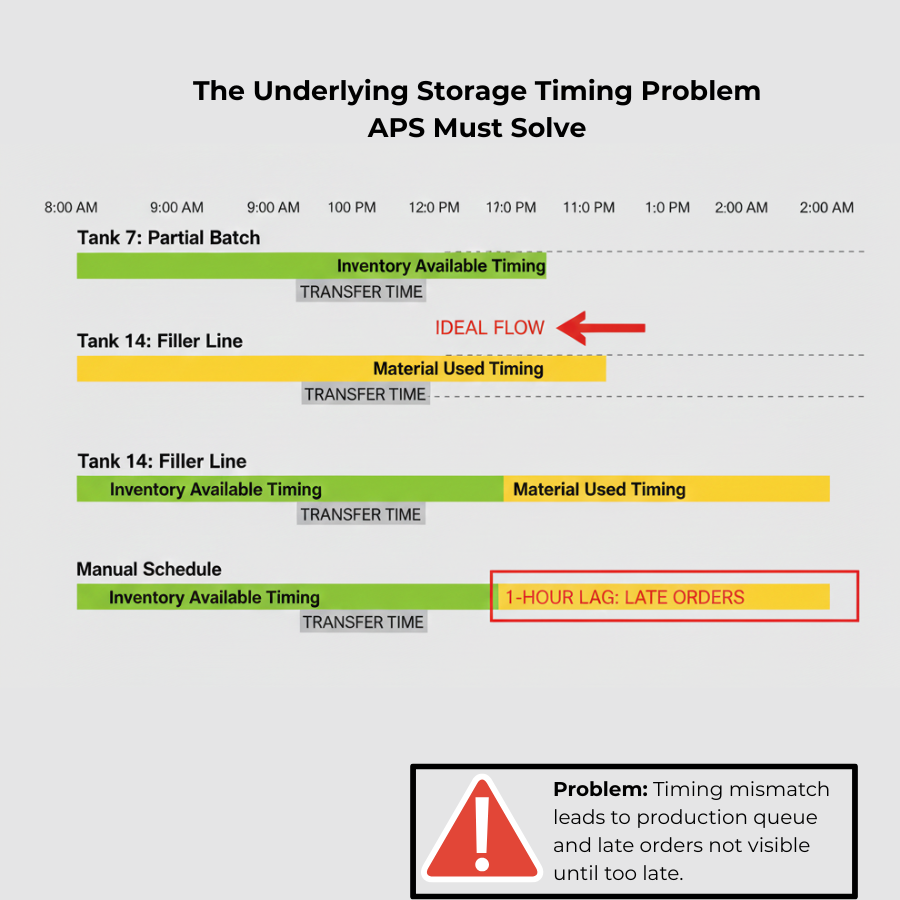

What complicates things is not only the tanks themselves. It is time. When material becomes available. When it should release. When another batch competes for the same pipe. These are the details that make or break a day, and they usually exist in someone’s notebook or email thread rather than the scheduling system.

PlanetTogether 12.3.0 introduces timing fields that actually match how chemical flow behaves in the real world. Inventory Available Timing and Material Used Timing let plants define the exact moment material counts as usable or consumed.

That might sound small. It is not. It is the difference between a schedule that looks correct and a schedule that is correct. It is also the difference between Tank 7 releasing product cleanly to a filler or creating a queue that ruins the afternoon. The scheduler discovers that a timing mismatch caused half their late orders. They saw it only after the fact. With 12.3.0, the schedule understands the timing upstream and downstream without the scheduler carrying it in their head.

The Filling Line, the Clock, and the Uneven Week

Once the batch reaches Tank 7, the next question looms.

Which filler can take it?

The schedule shows a slot at 6 am Friday. Another at noon. A third line sits open but requires a specific operator certification. Schedulers know this dance. The filling line giveth and it taketh away! And it always seems to break when a tank is close to its shelf life limit.

In this story, the scheduler hesitates. They know that shifting the batch to a different filler could trigger a full reschedule. Some tools force that. Some planners accept it because they have no choice. But the uncertainty is real dilemma:

Will this one decision scramble the rest of the week?

Will I regret touching anything at all?

PlanetTogether 12.3.0 softens that fear.

Job-specific optimization allows schedulers to optimize only what needs attention. Not the whole plant. Not the entire horizon. Just the piece that changed. Everything else remains locked and undisturbed. This is one of those features that is a nod to the scheduler's who have gone for a long time without this in any platform. Schedulers do not want heroics. They want control. They want the ability to fix what broke without breaking what worked.

I remember one scheduler telling me that a change on the filler felt like pulling a loose thread on a sweater. You never knew how much of the fabric would fall apart. Targeted optimization removes that guesswork.

The Data Insight That Saves a Weekend

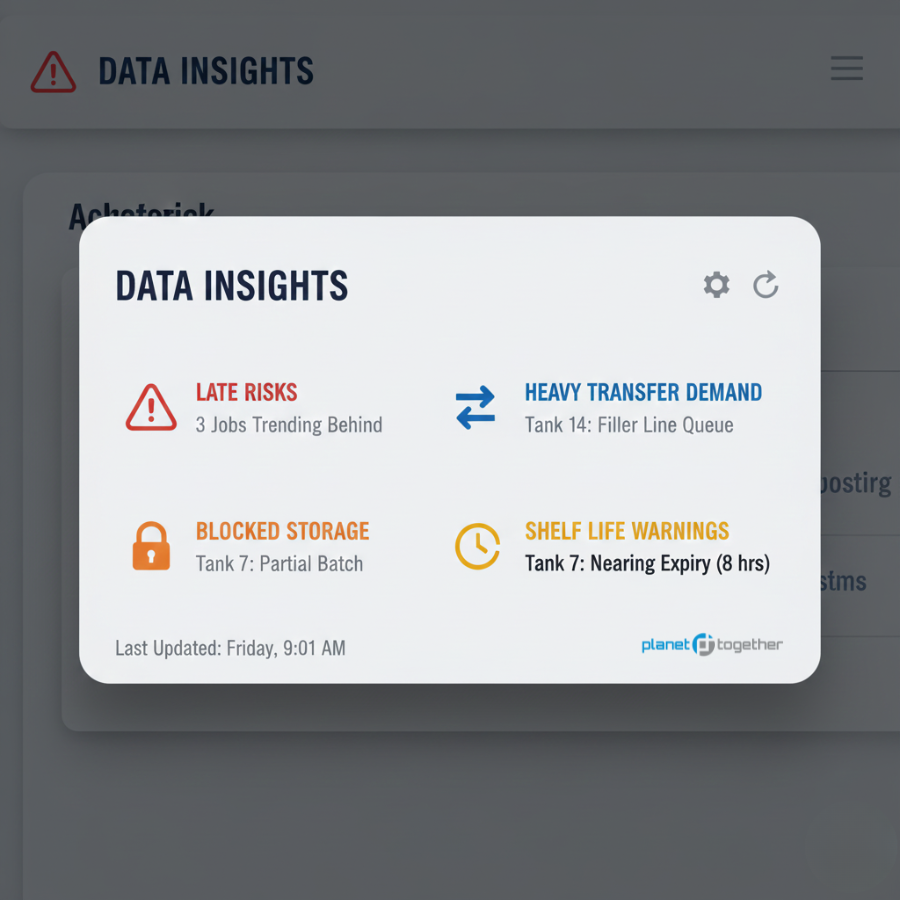

Friday morning arrives. The batch has not yet moved to the filler. Tank 7 now holds material nearing a shelf life warning window. The scheduler leans closer to the screen. A quiet sigh escapes before they even realize it. Important issues hiding just out of view. A tank approaching a deadline. A transfer load stacking up. A job trending late. The scheduler learns about it only when the problem is already burning.

PlanetTogether 12.3.0 introduces a Data Insights Tile that flags these issues before they turn into crises.

- Late risks

- Heavy transfer demand

- Blocked storage

- Shelf life warnings

All surfaced in one place.

I been on calls where schedulers show me their taped hand-written reminders to their monitors to compensate for missing system alerts. Now the system handles it. And in this story, the scheduler catches the shelf life risk early enough to adjust two filler assignments and avoid the problem entirely. It is not a dramatic fix. It is the kind of fix that prevents drama.

The Transfer That Connects It All

By the time the product reaches packaging, the week has already tested the scheduler's patience in several ways. Any chemical plant will do that. Equipment has its own personality. Tanks have their own attitude. Even the best crew cannot hold back unexpected flow constraints. Logistics waits in the background. Carriers want confirmation. Rail expects volume forecasts. Customer service wants assurance that everything will ship as promised.

PlanetTogether’s capacity utilization visual gives planners a way to check whether the production plan can support the outbound load. It is a simple idea. Yet simple ideas often fix the hardest problems. Planners get to see where capacity is consumed or idle, days before the truck ever arrives.

Sometimes the difference between a smooth Friday and a tense Friday is a single chart.

And when the shipment leaves the plant, the scheduler feels something almost strange. Relief mixed with confidence. The schedule held not because they muscled it into shape but because the system finally respected the actual rules of the plant.

Why This Story Matters to Chemical Schedulers

Chemical scheduling is not just math. It is chemistry meeting capacity. It is tanks meeting timing. It is people meeting pressure. And it rarely goes as the spreadsheet expects. Schedulers improvise more than most people realize. They do it quietly. They catch problems before anyone else sees them. They hold the week together through judgment and intuition.

The 12.3.0 release gives them a system that supports that intuition rather than fights it. Storage becomes real. Timing becomes explicit. Optimization becomes targeted. Alerts become proactive. The software begins to operate with the same awareness that schedulers already carry.

If a part of this story felt too close for comfort, that is not an accident. It is the rhythm of chemical plants we have worked with. The 12.3.0 release finally brings tank behavior, batch timing, and storage nuance into the light.

Schedule a PlanetTogether APS demo or talk with our team to see how your reactor to railcar journey can become clearer, calmer, and far more predictable.