Within all manufacturing facilities, lowering inventory levels and increasing service levels is by far one of the most important aspects to look into. Lowering inventory means reduced cost reduction and ultimately puts more money in your facility’s pocket.

This is where many facilities dive into lean concepts and tools that are commonly utilized to cut inventory costs. While lean is relatively common, Demand Driven Material Requirements Planning (DDMRP) is another concept that exploits the principles of lean and other methodologies while also modifying them to ensure that they are easily able to be executed. The most important key principle of DDRMP is that it separates DDMRP from other approaches through decoupling stock buffers.

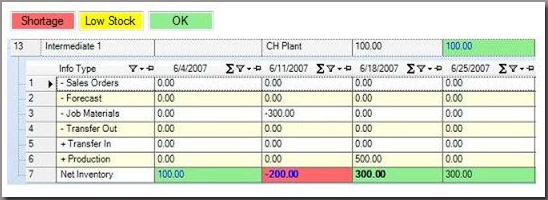

DDMRP takes advantage of the prepositioning of strategic decoupling stocks (or buffers) to ensure for reactivity to real demand and the organized management of supply priorities. This strategic mechanism allows for protection of relevant information flow as the system is established to set up buffers to absorb supply and demand variability. This ultimately limits the deviation from traditional planning logic triggers. It is important to understand the concepts behind DDMRP before attempting to integrate the methodology into your facility. It is also essential to understand the benefits associated with the methodology.

Benefits of DDMRP

Understanding the benefits of DDMRP can be extremely beneficial to your operation and can provide thorough insight on the concept. The benefits of DDMRP include the following:

- Agility Increase – As production and materials are reduced, you have more time and resources to respond to customer requests. Agility is essential within lean and DDMRP operations, due to concepts pertaining to inventory reduction as well as being more just-in-time focused. Agility will reduce waste through being able to respond to customers much more efficiently without creating mounds of inventory.

- Service Level Increase – Service levels can also be greatly increased as you can see both reduced lead times as well as improved performance on commitment dates. This is particular important as you are attempting to grow your business and bring in more customers.

- Overtime Reduction – In many production facilities, it is common for production changes to cause overtime and employees being held over due to scurrying trying to adapt. This is where the production facility sends out a red alert and needs everyone on deck, ultimately leading to overtime and staying late to finish runs. DDMRP can aid with this concept through buffering critical resources and not clogging up production with work that is not needed. As there are changes in demand, you are able to adapt to them.

- Higher Margins – The last benefit pertaining to DDMRP includes higher margins. Margins tend to suffer when manufacturers lower prices in order to win business or when overhead costs increase. DDMRP will allow manufacturers to cut lead times dramatically, meaning that they aren’t forced to reduce prices in order to compete. Higher margins are extremely beneficial to your operation as you increase profitability.

A software that can aid with DDMRP and utilizing resources to the fullest extent is PlanetTogether’s Advanced Planning and Scheduling (APS) Software. Advanced Planning and Scheduling (APS) Software is a must for manufacturing operations that are seeking to take their operation to the next level in terms of cost reduction, profitability increase, and overall operational efficiency enhancement.

Advanced Planning and Scheduling Software

Advanced Planning and Scheduling (APS) software has become a must for modern-day manufacturing operations due to customer demand for increased product mix and fast delivery combined with downward cost pressures. APS can be quickly integrated with a ERP/MRP software to fill gaps where these system lack planning and scheduling flexibility and accuracy. Advanced Planning and Scheduling (APS) helps planners save time while providing greater agility in updating ever-changing priorities, production schedules, and inventory plans.

See Where Smarter Material Planning Starts—Before You Go Demand-Driven

DDMRP helps you lower inventory, increase agility, and protect service levels by using strategic buffers and real-demand signals—not just forecast push. But to get there, it’s helpful to ground your team in how traditional material requirements planning (MRP) works today and where it falls short.

Download our Material Requirements Planning (MRP) infographic to quickly visualize how material planning should connect:

- Demand and supply across products and components

- Inventory levels and purchasing decisions

- Routings, lead times, and capacity-driven schedules

- ERP/MRP data with Advanced Planning & Scheduling (APS)

Use it as a one-page explainer to help your team understand the planning foundation that DDMRP builds on—and where APS can take your buffers, inventory, and schedules to the next level.

Video: Using PlanetTogether APS to Improve Capacity Planning

In this video, we show how PlanetTogether Advanced Planning and Scheduling (APS) helps manufacturers improve capacity planning. See how planners visualize resource load, align capacity with demand, and support demand-driven strategies like DDMRP without relying on static spreadsheets.

Key takeaways from this video:

- How PlanetTogether APS visualizes resource capacity and load in real time

- How to align capacity, inventory buffers, and demand in one schedule

- How what-if scenarios help choose the best capacity plan under changing conditions

- How capacity-aware APS supports demand-driven and DDMRP initiatives without adding complexity