Global air travel is an invaluable asset that provides a worldwide transportation network. Utility ranges from commercial passenger transit to transporting goods to bring together people, businesses, and communities. It’s imperative to safeguard aviation’s economic and societal benefits as the need for air transportation continues to grow. With this increased need comes additional challenges for the industry. More specifically, aircraft manufacturing needs to meet a growing demand for aviation while remaining conscious of our environmental fingerprint.

Industry leaders must answer this call for more environmentally friendly aircraft to remain competitive in their field. Challenges include expanding engineering and production capacity to meet these demands. With an expanding aviation sector, passenger demand doubles every 15 years and the air transportation industry could be handling as many as 16 billion passengers and 400 millions tons of cargo annually by 2050. As a result, many manufacturers are looking toward finite capacity scheduling as a helpful solution.

Let’s take a brief look into finite capacity scheduling and how one industry leader used this method to meet growing manufacturing demands.

Finite Capacity Scheduling

Finite capacity scheduling software is a decision-support tool that adjusts in real time to meet the needs of a multifaceted global company in the manufacturing space. This type of software helps assess the amount of work that can get done within a given time. Tools like these take resource constraints into consideration in order to ensure that work proceeds at a balanced and efficient pace throughout the production process.

Finite capacity scheduling stems from a customer-centric philosophy of providing the customers a 100% service level. Today, it is especially important to have a nimble process that manufactures products in a timely manner based on changing customer demand.

Finite capacity scheduling stems from a customer-centric philosophy of providing the customers a 100% service level. Today, it is especially important to have a nimble process that manufactures products in a timely manner based on changing customer demand.

Airbus

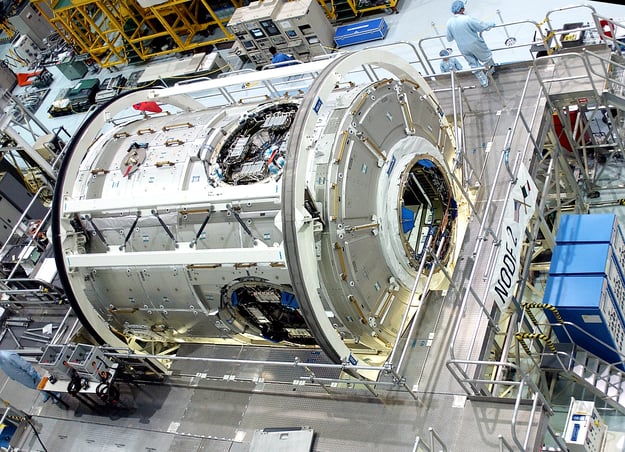

The functionality behind finite capacity scheduling works particularly well for geographically diverse companies. Airbus is an example of a company that fits nicely into that category. The aircraft manufacturer procures parts from five large depots across the globe in Hamburg, Frankfurt, Washington D.C, Singapore, and Peking. With more than two million different spare parts in the Airbus database, keeping up with this equipment is a serious task. Fortunately, Airbus initiated their Advanced & Integrated Planning Project several years ago to optimize the provision of these spare parts in conjunction with the stock at storage locations. This initiative also helps them control costs.

In using finite capacity software, Airbus has optimized their inventory flow, shortened delivery times, and accurately planned their manufacturing process to meet changing demand. Their success came from a software planning solution that enabled them to optimize their demand and delivery chain network. Finite capacity scheduling software also allowed them strategic, tactical, and operational planning capabilities—the basis for substantial competitive advantage and customer satisfaction.

Airbus achieved a return on investment in little over a year. The savings in their delivery chain thus far from the initiative are in the millions.

Related Capacity Video

APS Resources