Quick Answer: The 5 Components of Production Scheduling

Production scheduling turns demand into executable work. A complete cycle includes:

- planning quantities and timing

- routing the steps and resources

- scheduling jobs against real capacity

- dispatching prioritized work to the floor

- executing and feeding back actuals.

APS connects these steps so schedules stay feasible when constraints or priorities change.

Production scheduling has become a must for manufacturing operations that are looking to take their production facility to the next level. Production scheduling refers to the allocation of resources, operations, and processes required to create goods and services.

Businesses can adjust their production scheduling based on the availability of resources and client orders. The goal of a production schedule is to adequately balance customer needs with the resources that are available whilst operating in a cost-effective manner. If the production schedule you create is not accurate and feasible given your available resources, you will have problems getting items produced and delivered to your customers on time.

5 Components of Production Scheduling

The five components of production scheduling include the following:

1. Planning

The planning component of production scheduling is by far the most important. This component pertains to deciding what will be done in the future. Without a plan, production scheduling can not even begin or take place. Preparing a plan through charts, production budgets, or various others visual representations can provide a sound basis for steps down the road pertaining to production. There are two types of planning that can be used: static planning and dynamic planning. Static planning assumes that all steps will be completed on time with no changes, while dynamic planning assumes that some process steps will change.

2. Routing

Production routing is the process that is used to determine the route or path that a product must follow. This route entails the path from raw materials until it is transformed into a finished product. The main objective of this component is to locate and perform the most economical and enhanced sequence of operations in the production process.

3. Scheduling

Scheduling coincides with the time and date that the operation must be completed. Scheduling is an essential and crucial portion of production scheduling and lays the foundation and groundwork for all of the steps within the production process. There are three types of scheduling that an operations utilize, such as master scheduling, manufacturing or operation scheduling, and retail operation scheduling. Overall, scheduling is key for a manufacturing operation to proceed.

4. Dispatching

Dispatching relates to the process of assigning the order of job from the preconceived production plan. Dispatching is concerned with giving a practical shape to an overall production plan. This will also include issuing any orders and instructions and other important information pertaining to production.

5. Execution

The last component of production scheduling is the proper execution of the created schedule. Staff members must work together to ensure that items are produced in the right order and delivered on time. A proper schedule execution would be one that has the fewest amount of bottlenecks or late orders.

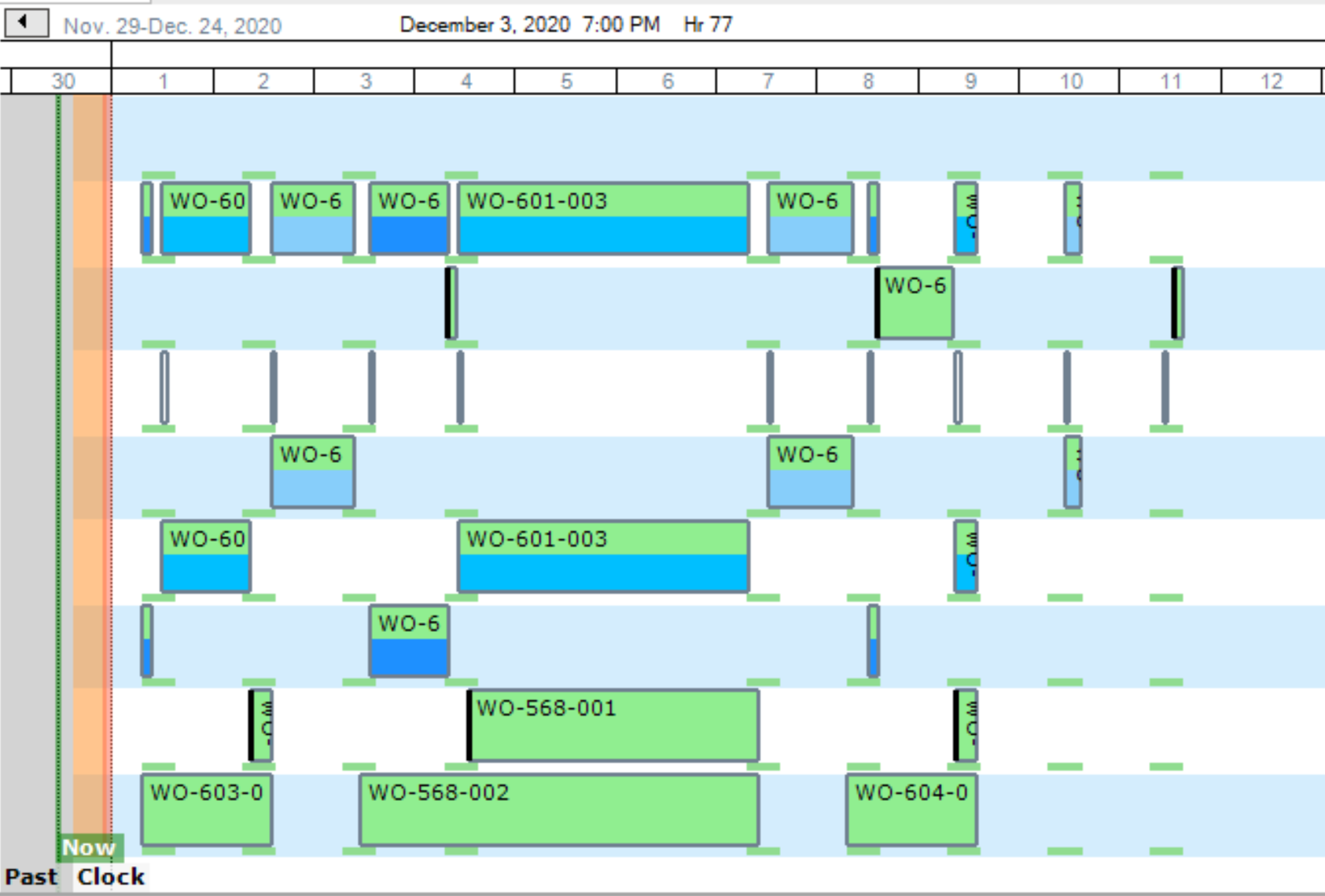

An Advanced Planning and Scheduling Software (APS) utilizes the five components of production scheduling to help your manufacturing facility plan, route, schedule, dispatch, and execute your production schedule. These systems can provide thorough insight within your manufacturing operation.

Before, it took hours to schedule [our production] manually because scheduling was based on reports. Now, it only takes seconds.

LES HOWELL, EXECUTIVE DIRECTOR OF IT, ILLES SEASONINGS & FLAVORS

Decision Framework: Where to Focus Your Scheduling Improvements

Use this quick diagnostic to find the “break” in your scheduling loop:

- Planning problem? If demand changes weekly and your plan becomes obsolete fast, focus on faster replanning + scenario checks.

- Routing problem? If routings are outdated or inconsistent, fix process steps, alternates, and constraints

- Scheduling problem? If schedules ignore capacity/setup/downtime, you need finite (constraint-based) scheduling.

- Dispatching problem? If priorities shift mid-shift and teams don’t know what’s next, tighten dispatch rules + visibility.

- Execution problem? If actuals aren’t captured quickly, scheduling will always lag—improve feedback loops (WIP status, completions, exceptions).

Advanced Planning & Scheduling (APS) Software

Production scheduling only works when the full cycle is connected—planning, routing, scheduling, dispatching, and execution. In real plants, that cycle breaks when priorities shift, constraints change, or the schedule is built on assumptions that don’t match shop-floor capacity. APS adds the constraint-aware layer that helps teams build feasible schedules and update them quickly as conditions change.

APS also complements ERP/MRP by using the operational data you already maintain (items, routings, orders, calendars) while improving scheduling accuracy and flexibility—especially when you need finite-capacity sequencing, bottleneck protection, and fast re-planning.

With PlanetTogether APS, you can:

- Create feasible, optimized schedules that balance efficiency and delivery performance

- Maximize throughput on bottleneck resources by sequencing work around real constraints

- Synchronize supply with demand to reduce excess inventory and WIP

- Improve visibility into resource capacity across teams for faster coordination

- Run what-if scenarios to make data-driven tradeoffs when priorities or conditions shift

Kinaxis Production Scheduling: Finite-Capacity APS with PlanetTogether

Production scheduling isn’t just “putting jobs on a calendar.” It’s coordinating resources, operations, and processes so work can be completed in the right sequence and delivered on time. This video explains how Kinaxis Production Scheduling by PlanetTogether supports constraint-aware scheduling—so your plan reflects real capacity and execution realities.

You’ll also see how modern scheduling connects the core building blocks of production control—planning, routing, scheduling, dispatching, and execution—to reduce bottlenecks and late orders. For production planners, schedulers, operations leaders, and supply chain teams, this helps move from “best guess” schedules to schedules you can actually run on the floor.

Finally, the video shows where Advanced Planning & Scheduling (APS) fits: an APS system applies those five scheduling components to help manufacturers plan, route, schedule, dispatch, and execute more consistently—often by integrating with ERP/MRP to close gaps in scheduling flexibility, accuracy, and efficiency.

Download the Infographic: Spreadsheet Scheduling vs. APS (See the Time Difference)

If your production schedule lives in spreadsheets, you already know the hidden cost: the schedule is only “accurate” until the next status change, expediting request, material shortage, or priority shift. Then the day becomes manual refreshes, copy/paste rework, and constant follow-up—just to keep the schedule usable.

Download our infographic comparing spreadsheet-based scheduling vs. APS-based scheduling to see where time is typically lost—and what changes when scheduling is built specifically for manufacturing execution. It’s a fast, practical resource for production schedulers and operations teams who want quicker schedule updates, easier what-if adjustments, and clearer communication to the floor.

In the infographic, you’ll see side-by-side time comparisons for:

- Refreshing planning data (minutes) vs. gathering status updates (hours)

- Optimizing a schedule vs. chasing new order and inventory info

- Running what-if schedule adjustments vs. spotting exceptions/issues

- Communicating the schedule vs. copy/pasting jobs to resources

- Typical daily time impact: about one hour vs. a full shift

Production Scheduling FAQs

What are the five components of production scheduling?

Planning, routing, scheduling, dispatching, and execution. Together, they connect demand to shop-floor reality—defining what to make, how it flows, when it runs, what gets released next, and how actual results update the plan.

What’s the difference between planning and scheduling?

Planning sets targets (what/when/how much). Scheduling assigns work to specific resources over time based on constraints like capacity, changeovers, labor, and material readiness.

Why does routing matter for schedule accuracy?

If routings are incomplete or outdated, schedules are built on incorrect assumptions—wrong work centers, missing steps, unrealistic run times—so the plan looks “optimized” but fails on the floor.

What is dispatching in production control?

Dispatching is the release of the next prioritized work to the shop floor—work orders, sequences, and instructions—so teams know what to run now and what to run next.

How does APS improve production scheduling?

APS helps teams build feasible schedules using real constraints, then quickly re-optimize when priorities change. It also supports scenario planning so planners can compare tradeoffs before committing.

See Constraint-Based Scheduling in Action

Want to replace spreadsheet scheduling with feasible, constraint-based schedules your team can actually run? Request a PlanetTogether APS demo.