Making it easy to source material from alternate plants

How to simplify sourcing and scale planning across all your plants

Planning and scheduling are both essential for managing production—but they serve different purposes. Scheduling focuses on the day-to-day execution within a single plant: what’s being produced, in what order, and on which machines. Planning, on the other hand, takes a broader view. It allows you to look ahead, balance demand and capacity, and make strategic decisions—especially when managing multiple plants.

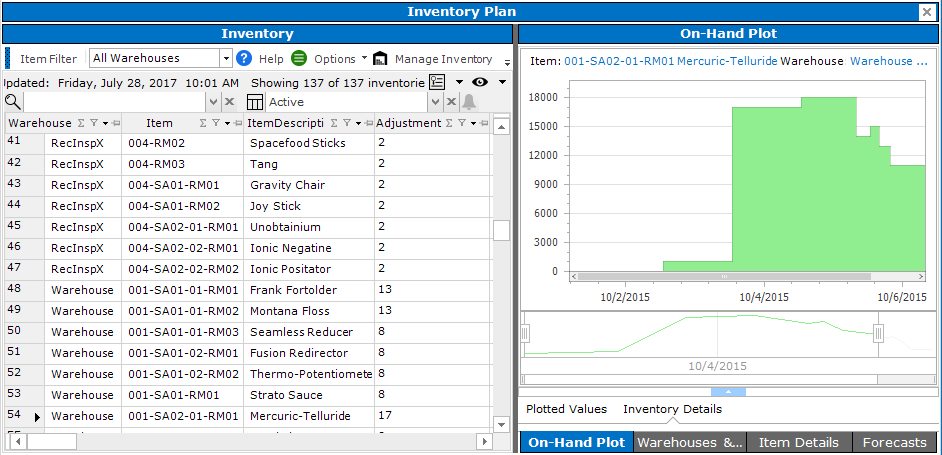

Multi-plant capacity planning helps manufacturers coordinate production across different facilities. With PlanetTogether, you can easily compare capacity, inventory levels, and material availability across plants. This makes it simple to source from the best location—whether that’s the one with the most available stock, the shortest lead time, or the closest proximity to your customer. Our Inventory Plan provides visibility into multiple warehouse locations, so you can make data-driven decisions and respond quickly to changes in demand or production conditions.

Plan ahead with greater visibility and flexibility

PlanetTogether’s multi-plant functionality enables long-term planning across your entire operation. You can identify capacity or material bottlenecks before they impact production and adjust accordingly. For more focused planning, our Single Plant Optimize feature lets planners fine-tune the schedule within one plant, while still operating within the larger, connected network. This flexibility supports both independent and interdependent plant strategies—whichever works best for your business.

Expand long-term planning companywide for greater visibility

With PlanetTogether, you’re not just planning inside each plant—you’re planning across the company. Multi-plant functionality lets you identify and solve problems before they happen by spotting capacity constraints, material shortages, or equipment changes early on. You can optimize each plant individually using our Single Plant Optimize feature, or plan collectively, depending on how interconnected your operations need to be.

Discover the full benefits of Multi-Plant Scheduling with the following video.

Video: Multi-Plant Planning & Scheduling with PlanetTogether APS

In this video, you’ll see how PlanetTogether Advanced Planning & Scheduling (APS) supports multi-plant planning and scheduling for manufacturers running multiple facilities, products, and customer segments. Learn how APS gives managers real-time visibility into capacity, constraints, and order status across sites so strategic decisions are based on timely, trusted data—not outdated spreadsheets or static reports.

The video demonstrates how multi-plant APS helps you coordinate production plans between locations, reallocate work when demand or constraints change, and evaluate what-if scenarios before you commit to a new schedule. By integrating with ERP/MRP and other business systems, PlanetTogether APS turns planning and scheduling tools into a core component of strategic management, aligning operational decisions with company-wide goals.

This video is ideal for operations leaders, planners, and executives who want planning and scheduling technology that supports strategy formulation and execution—not just day-to-day rescheduling on the shop floor.

Make Strategic Management Work on the Production Floor

Setting strategy is only half the job. To keep up with shifting market forces and customer demands, managers need planning & scheduling tools that turn real-time operations data into clear, actionable production plans. When schedules live in spreadsheets or weekly reports, it is almost impossible to adapt quickly without sacrificing efficiency or customer satisfaction.

Download our one-page “The Money Is in the Planning” infographic to see how advanced planning and scheduling can help you:

- Connect strategic objectives directly to daily production plans and capacity decisions

- Replace rigid, linear planning with collaborative, data-driven scheduling across plants, products, and customers

- Give managers real-time insight so schedule changes are smarter, faster, and better aligned with company goals

- Reduce waste and excess inventory while keeping customers satisfied with reliable delivery

- Turn strategic management from an annual exercise into a continuous, operations-driven practice

Share it with your leadership, planning, and operations teams as a quick visual guide to where planning & scheduling tools + APS deliver the biggest strategic impact.