Companies that have not yet implemented lean concepts into their current practices may find it daunting, especially since lean aims for perfection and waste elimination. When a business has a significant amount of room for process improvement, companies may feel overwhelmed and unsure where to begin. As tackling all areas of improvement at once is not feasible, it can be difficult to prioritize. Integrating the Theory of Constraints (TOC) into the equation, however, pinpoints exactly which area needs the most improvement and can add the most value to the company.

Where TOC and Lean Meet

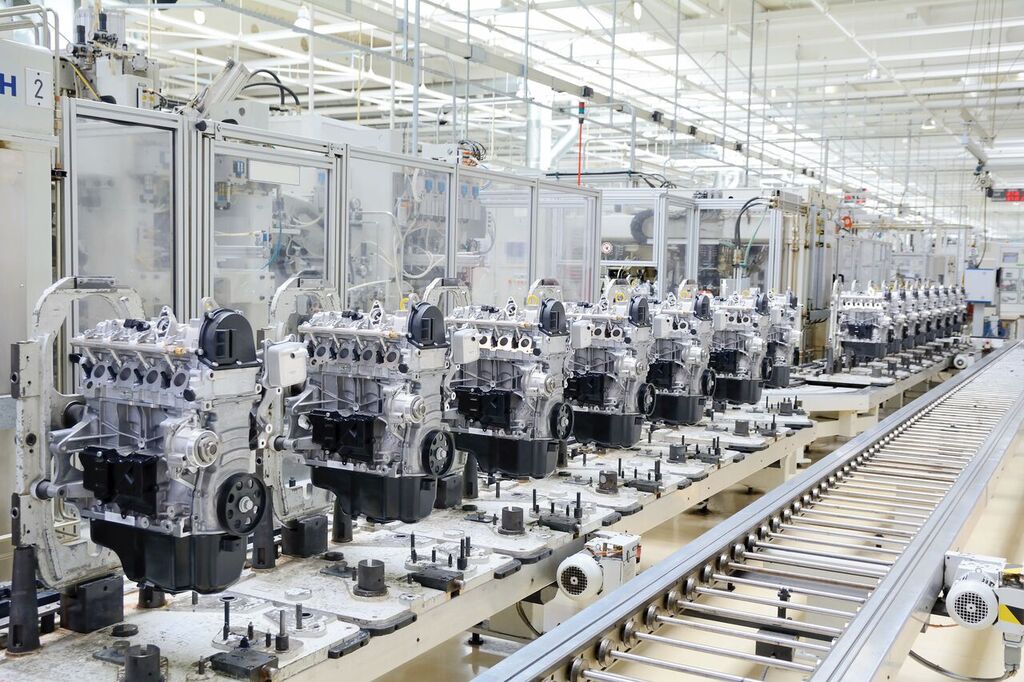

While Lean is a school of thought and TOC is a methodology, both use a "pull" system to keep on-time delivery consistent. Furthermore, applying these concepts is not a one and done process. Both styles require continuous improvement to promote ongoing operational efficiency. Before any improvements are made, however, the staff must have an in-depth understanding of the manufacturing process flow down to every painstaking detail. Once the value of each step of the production process is mapped, stakeholders can begin to implement changes that enhance the product's value both to the manufacturer as well as from a customer's perspective.

Key Differences

Lean and TOC also differ in certain areas. For example, lean inherently segments a company into individual parts that can each be analyzed and improved. TOC, on the other hand, focuses on a single constraint that can be improved and benefit the company holistically. While both systems aim to promote efficiency, each does it a slightly different way. Namely, lean's focus on reducing lead time and inventory to cut waste provides benefits in the form of less inventory and removing any non-value driven tasks in a process. TOC also focuses on reducing lead time and inventory but for different reasons. The Theory of Constraints aims is to improve capacity, throughput, and essentially, develop a greater competitive edge.

A TOC-Lean Approach

When implementing a hybrid approach, data analysis is imperative, whether it be through a value stream map or another detailed aggregation of relevant data on the limiting factors. Employee training will also be needed to understand both TOC and lean principles. Once data has been collected for company processes, a detailed plan of the hybrid implementation process can begin. Throughout the implementation process there must be a supervisor or mentor that can quickly answer questions regarding strategic direction and overcome any obstacles.

Drum Buffer Rope

TOC maximizes the constraint capacity through a drum-buffer-rope approach (DBR). The drum in this approach is the pace of production set by the constraint. The buffer ensures there are enough resources in case of an unexpected capacity change. The rope in this scenario ensures that production flows in an efficient manner by introducing new work once the constraint finishes its current task. As the old adage goes, "a chain is only as strong as its weakest link." Implementing a hybrid approach enhances the manufacturing process more than using lean or TOC alone. Companies effectively realize improvements with lead time reduction, lower inventory and utilizing resources to their maximum potential.

Video: Lean & Theory of Constraints – Minimizing Waste with APS

Lean manufacturing focuses on eliminating waste, while the Theory of Constraints (TOC) focuses on improving the one constraint that has the biggest holistic impact on performance. Both rely on a pull system and require continuous improvement, but TOC adds a targeted, constraint-first lens that is especially powerful when combined with Lean.

In this video, you’ll see how PlanetTogether Advanced Planning & Scheduling (APS) helps manufacturers apply Lean and TOC together to:

- Identify and manage the system constraint, increasing capacity and throughput where it matters most

- Support a pull-based flow, keeping on-time delivery consistent while reducing lead time and inventory

- Implement a hybrid Lean–TOC approach using tools like Drum-Buffer-Rope, where the constraint sets the pace (drum), buffers protect the constraint, and the rope controls release of work into the system

- Use detailed production data and scheduling logic to sustain improvements instead of treating Lean or TOC as one-time events

This video is ideal for operations leaders, continuous improvement teams, and planners who want to combine Lean manufacturing, TOC, and APS to minimize waste, increase capacity, and gain a competitive edge.

Turn Lean & TOC Insights into a Constraint-Focused Production Plan

Applying Lean manufacturing and the Theory of Constraints together can feel overwhelming—there are many forms of waste to eliminate and only one true system constraint that sets the pace. Without a strong planning and scheduling layer, it is difficult to translate value stream maps, bottleneck analyses, and Drum-Buffer-Rope designs into a daily production plan your team can actually follow.

Download our one-page “The Money Is in the Planning” infographic to see how combining Lean, TOC, and Advanced Planning & Scheduling (APS) helps you:

- Focus improvement on the true constraint, increasing throughput without adding more equipment

- Reduce lead time and inventory by aligning flow, buffers, and release of work with the constraint’s pace

- Use your existing operational data to build constraint-aware production schedules that support Drum-Buffer-Rope

- Sustain continuous improvement by making capacity, queues, and bottlenecks visible in one planning environment

- Turn Lean and TOC initiatives from one-time projects into everyday scheduling discipline that protects flow and profitability

Share it with your Lean, TOC, and operations teams as a quick visual guide to where better planning and scheduling with APS makes hybrid Lean–TOC implementations stick.