With any product, there are particular attributes that consumers will favor over others. This permits trade-offs, leaving it up to the consumer to decide what attributes about the product they can and can not do without.  Any item or step within the product process that is non-beneficial to the consumer is considered wasteful - which is why utilizing a value stream map can be advantageous. Value stream mapping is a lean manufacturing technique that enables your operation to be able to analyze, document, and enhance information or material flow within your supply chain. This process easily allows you to identify areas of waste and produce a much more consumer-oriented product.

Any item or step within the product process that is non-beneficial to the consumer is considered wasteful - which is why utilizing a value stream map can be advantageous. Value stream mapping is a lean manufacturing technique that enables your operation to be able to analyze, document, and enhance information or material flow within your supply chain. This process easily allows you to identify areas of waste and produce a much more consumer-oriented product.

7 Waste within Value Stream Mapping in Manufacturing

Value stream mapping aids in identification and elimination of the seven common waste within manufacturing:

- Overproduction - Although it may seem like creating large sums of product is beneficial, it can bring harm to your production flow and quality. Overproduction only increases storage and lead time waste within your production facility.

- Waiting - Maintenance, downtime, inefficient transportation, or any loss of productivity can lead to a big loss in revenue.

- Conveyance - Waste is prevalent within this area of manufacturing, including acts of double-handling and excessive movement.

- Stock Surplus - Along with overproduction, too much inventory leads to increased holding cost and lead time. This is why it is important to have production flow as efficiently as possible.

- Wasted Energy - This area of waste pertains to any unnecessary movement by employees such as stretching or bending. Any unnecessary movements bring absolutely zero benefit to the facility.

- Processing - Poor processing includes unsafe production, pertaining to inferior communication and unnecessary motion.

- Mistake Correction - Defects only cost production facilities money, which is why it is extremely important to try and make sure the product is correct the first time around.

Value Stream Mapping in Manufacturing Benefits

Value stream mapping is extremely advantageous to your facility and can promote thorough insight with ease. Various benefits of value stream mapping include the following:

- Quick to Learn

- Cost Reduction

- Inexpensive

- Identify Bottlenecks

- Inclusive Program (Workforce Involvement)

Although these are just a few of the benefits of value stream mapping, it can benefit various fields as well.

Value Stream Mapping Utilization in Various Fields

- Logistics - Reduce and eliminate waste within the supply chain by identifying the inefficient points of production.

- Software Engineering - Find inefficiencies in software development such as rework and feedback loops. Utilizing VSM will reduce time between steps and eliminate rework need.

- Manufacturing - Value stream mapping is most beneficial to manufacturing and enables the facility to take a deeper look into their production. This enables the facility to easily identify steps in which consumers consider non valuable and enforce a strategy to eliminate the steps. This can reduce waste within the operation significantly and allow for a much more concise and efficient production flow.

- Healthcare - Improve steps to take in order to treat patients in a more timely and effective manner.

Advanced Planning and Scheduling (APS) with Value Stream Mapping

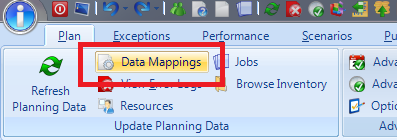

Advanced planning and scheduling (APS) can be utilized with lean manufacturing and value stream mapping. APS ensures for an optimized production flow and aids in eliminating the seven common waste of lean manufacturing. APS can successfully enhance your operation through the following capabilities:

- User Interface

- Multi-Plant, Multi-User

- Real-Time Analytics

- What-if Scenarios

Enhance your operation with ease and quickly turn your production facility into a profit center through integration of an advanced planning and scheduling (APS) system.

Video: Lean Value Stream Mapping – Minimizing Waste with APS

Value stream mapping (VSM) is a lean manufacturing technique that visualizes material and information flow so you can identify and eliminate the seven common wastes—overproduction, waiting, conveyance, stock surplus, wasted energy, poor processing, and mistake correction.

In this video, you’ll see how PlanetTogether Advanced Planning & Scheduling (APS) turns VSM insights into a practical, executable production plan by:

- Using VSM to highlight bottlenecks and non-value-added steps, then applying APS logic to smooth flow and balance loads

- Combining a modern user interface, multi-plant/multi-user scheduling, and real-time analytics to monitor and improve material and information flow across the value stream

- Running what-if scenarios to test changes to sequences, capacity, and inventory policies before making them live

- Supporting a lean culture by making waste, queues, and delays visible on the schedule instead of hidden in spreadsheets

This video is ideal for Lean leaders, CI teams, and production planners who want to use value stream mapping plus APS to systematically reduce waste, shorten lead times, and improve throughput.

Turn Your Value Stream Map into a Waste-Free Production Plan

Value stream mapping (VSM) gives you a clear picture of your current state—where waste hides in overproduction, waiting, movement, stock surplus, wasted energy, poor processing, and rework. It is quick to learn, inexpensive, and excellent at highlighting bottlenecks and inefficiencies across the value stream.

But to fully realize the benefits, you need a planning engine that converts those insights into a realistic, optimized production schedule. That is where Advanced Planning & Scheduling (APS) comes in.

Download our one-page “The Money Is in the Planning” infographic to see how combining Lean value stream mapping with APS can help you:

- Move from static maps and workshops to a living, constraint-aware schedule

- Use APS to reinforce your VSM improvements by smoothing flow, reducing WIP, and protecting bottlenecks

- Leverage multi-plant, multi-user capabilities to extend lean improvements across facilities

- Apply real-time analytics and what-if scenarios to test kaizen ideas before you change the shop floor

- Turn your production facility into a true profit center by aligning planning, scheduling, and lean waste elimination

Share it with your Lean, CI, planning, and operations teams as a concise visual guide to where value stream mapping plus APS delivers measurable, ongoing improvement.