Successful demand planning within a manufacturing operation is a challenge many project managers struggle with. Demand planning calls for various attributes such as reliable consumer data to be able to forecast accurately.

Without accurate data, the whole system becomes unreliable, and production is unsure of how much to produce - especially in swift demand changing circumstances. Therefore, implementing a demand planning system such as SAP demand planning can efficiently improve your manufacturing operation. SAP can be augmented further with advanced planning and scheduling system software (APS), allowing refinement at the macro and micro levels.

Without accurate data, the whole system becomes unreliable, and production is unsure of how much to produce - especially in swift demand changing circumstances. Therefore, implementing a demand planning system such as SAP demand planning can efficiently improve your manufacturing operation. SAP can be augmented further with advanced planning and scheduling system software (APS), allowing refinement at the macro and micro levels.

SAP Demand Planning Software - Implementation

Implementation of SAP demand planning is quick and simple, though, often not the be-all-end-all in terms of a final, best and total solution (see "Advanced Planning and Scheduling (APS) Integration of SAP Demand Planning" section below). Defining the most important attributes of your production facility and establishing the key figures that affect your demand is a first step in the process of implementation.  As these figures are considered, presenting actual and historical data into the system will allow for accurate forecasting and development of a plan for a varying demand. Other key factors in demand planning implementation include the following:

As these figures are considered, presenting actual and historical data into the system will allow for accurate forecasting and development of a plan for a varying demand. Other key factors in demand planning implementation include the following:

- Forecast Management

- Supply and Demand Collaboration

- Customer Confirmation

- Reexamination of Data

- Statistical Forecast

Thoroughly analyzing all of these key factors will allow for enhancement of your demand planning process and provide a simple integration of demand planning methods.

SAP Demand Planning Software - Benefits

SAP demand planning has various benefits that can be extremely beneficial to manufacturing operations that are wanting to improve demand planning. Along with simple and quick implementation, various benefits include the following:

- Enhanced Demand Flexibility

- Integrated System

- Increased execution

- Strategic Resource Allocation

These benefits and capabilities will adequately improve your manufacturing operation and optimize your demand and production through data accuracy, system integration, and overall operational efficiency.

Advanced Planning and Scheduling (APS) Integration of SAP Demand Planning Software

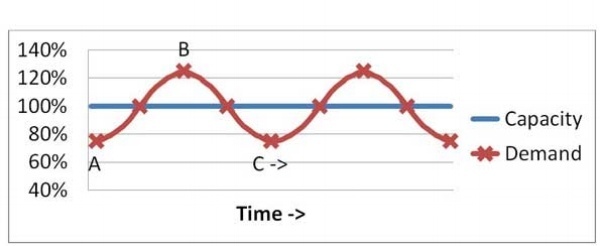

Advanced planning and scheduling (APS) software is a robust extension of an ERP system such as SAP, and allows for a far more deeper insight into demand planning. Through presented up-to-the-minute data, an integrated ERP/APS system can accurately respond to forecasted demand. Together, the capabilities and benefits of an integrated solution capitalizes on the sum of parts and can greatly improve response to an ever-shifting demand.

Visualizing Demand vs. Capacity with the Inventory Plan in PlanetTogether APS

See how PlanetTogether APS helps you visualize demand and capacity in one place. In this video, you’ll use the Inventory Plan to see how upcoming demand, current inventory, and available resource capacity line up over time—so floor managers can quickly spot when demand planning will overload production, drive overtime, or starve critical orders. It’s an ideal next step if you’re trying to connect demand planning, SAP/ERP data, and real-world capacity using advanced planning and scheduling instead of spreadsheets.

Align Demand and Capacity—And Stop Letting Overtime Eat Your Margin

In this article, you’ve seen how demand planning and resource planning often pull in different directions. Demand planning pushes for higher volumes to hit revenue targets, while resource planning is constrained by the people, machines, and time you actually have. The result is all too familiar: scrambling on the shop floor, last-minute overtime, and profit surprises when the numbers finally land.

With the right production planning and APS software, you can connect demand forecasts (from SAP or other ERP systems) to a realistic model of your capacity, so you can meet demand without constantly burning overtime and firefighting.

Our eBook, “Producing for Profit,” shows what this transformation looks like inside a real manufacturing business. You’ll follow a growing manufacturer that’s struggling with late orders, rising overtime, and constant friction between sales and production—until they adopt a connected planning and scheduling system that aligns demand, capacity, and cost.

In this short eBook, you’ll see how they:

- Replace reactive, spreadsheet-based scheduling with a data-driven production plan

- Use APS to align demand planning with real capacity, so they can meet orders inside normal shifts instead of relying on expensive overtime

- Improve on-time delivery while reducing expediting and excess inventory

- Free planners from manual juggling so they can focus on improving margins and service instead of just surviving the week

If you’re ready to stop choosing between satisfying demand and protecting profit, this eBook is your next step.