The creation of production schedules within manufacturing has become a much easier process with the emergence of drag-and-drop scheduling. This type of scheduling pertains to creating a production schedule using software that allows you to simply drag jobs or operations to where you want them to start on the production timeline and release them once you have reached the desired time point.

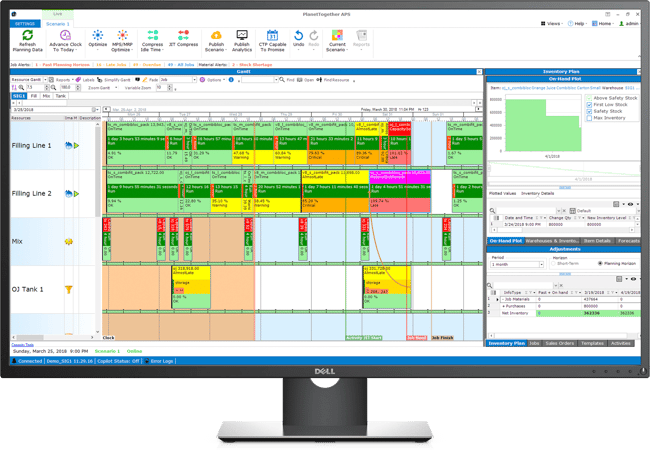

This is a much easier and faster process than pen and paper scheduling or even scheduling using spreadsheets. Drag-and-drop scheduling in an Advanced Planning and Scheduling (APS) software such as PlanetTogether APS allows you to re-order jobs from grid-like views or from a Gantt chart view. This will allow you to have more visibility into when a job should start and see the impact on other jobs when you change the sequence of jobs through drag-and-drop.

Before implementing a production planning and scheduling software with drag-and-drop functionalities, it is important to understand the advantages and disadvantages of the feature and how it pertains to your manufacturing operations. Therefore, here are the advantages and disadvantages of drag-and-drop scheduling within your production planning process.

Advantages of Drag & Drop Scheduling in Manufacturing

The advantages of drag and drop scheduling in manufacturing include the following:

- Simplicity - Simplicity is by far one of the most substantial benefits of utilizing drag-and-drop. This is because drag-and-drop eliminates the need to look at spreadsheets or manually enter in numbers. You are able to click on a job and then simply place the cursor where you want the task to start and release it. Subsequent jobs or operations will also be automatically moved backward or forward in time to eliminate gaps in the schedule. It really is that simple.

- Reallocate With Ease - Drag-and-drop is also compatible with easy reallocation of jobs to resources. If a job is able to be performed by another resource, it can be dragged to another resource’s timeline. In PlanetTogether, you will get a visual indicator on the Gantt view that alerts you of which resources are capable of completing the job. You are unable to do this with spreadsheets, which is why operation managers are implementing this feature on a frequent basis.

- Visual Nature of It - Drag and drop scheduling allows you to easily visualize your production process. Another benefit of visual production scheduling is that it can make it easier for everyone to see the status of production. This will allow you to quickly identify production bottlenecks, material shortages, and simplify the process of creating an optimized production schedule. You will be able to make crucial financial decisions such as when to start a new project or where additional resources are needed in order to complete work orders on time and meet your production goals.

While there are many advantages to drag and drop within the production planning process, there are also a variety of disadvantages as well.

Disadvantages of Drag and Drop Scheduling in Manufacturing

The disadvantages of drag and drop scheduling in manufacturing include the following:

- Lacks Detail - If you are simply dragging and dropping assignments and tasks all over the place and not going into detail, then you will not have detailed plans. It may be okay if you are wanting to simply visualize your schedule, but it is not necessarily ideal when you need to perform the task as well. Therefore, if you are going to actually implement the plan, take a look at the details as well. It is important to consider planning and scheduling softwares that provide multiple ways of looking at the schedule, such as having a Gantt chart and then more detailed grid-like production schedules.

- Can Be Complex With Lots of Data - Having a substantial amount of data is already challenging enough, and unfortunately it can make resource scheduling complex as well. Dragging and dropping a ton of tasks can actually be more time consuming than adding them utilizing a bulk import, making copies, etc.

- Editing is Still a Factor - While it still is incredibly easy to add tasks, it is also extremely easy to make mistakes, which means you will still need to edit the task duration. You also need to ensure that you are dragging-and-dropping jobs on resources that can actually perform the work, and that you have all of your materials on hand to start the job. While this can be challenging, an APS system like PlanetTogether automatically takes these factors into consideration and will prevent the job from scheduling if the resource does not have the required capabilities for it or if not enough materials are available.

A software that can easily take your production facility to the next level is PlanetTogether’s Advanced Planning and Scheduling (APS) software.

Life will be easier for any manufacturer who chooses PlanetTogether. It’s an efficient scheduler, plain and simple.

JAIME OZUNA, PRODUCTION SCHEDULER, ATLANTIC COFFEE

PlanetTogether APS provides a visual Gantt chart with drag-and-drop that allows you to have full control over your production schedule. The visual representation of tasks will provide direct insight into areas that are in need of optimization, where any constraints may occur, and aid in the decision-making process to fix potential issues before they arise. In addition, PlanetTogether APS provides drag-and-drop functionalities from its grid views, which allows for easy re-sequencing on resources for those who feel more comfortable with spreadsheet-like production schedules.

Advanced Planning & Scheduling (APS) Software

Advanced Planning and Scheduling software has become a must for modern-day manufacturing operations as customer demand for increased product assortment, fast delivery, and downward cost pressures become prevalent. These systems help planners save time while providing greater agility in updating ever-changing priorities, production schedules, and inventory plans. APS Systems can be quickly integrated with an ERP/MRP software to fill the gaps where these systems lack planning and scheduling flexibility, accuracy, and efficiency.

With PlanetTogether APS you can:

- Create optimized schedules that balance production efficiency and delivery performance

- Maximize throughput on bottleneck resources to increase revenue

- Synchronize supply with demand to reduce inventories

- Provide company-wide visibility to resource capacity

- Enable scenario data-driven decision making

The implementation of an Advanced Planning and Scheduling (APS) Software will take your manufacturing operations to the next level of production efficiency by taking advantage of the operational data you already possess in your ERP system. APS is a step in the right direction of efficiency and lean manufacturing production enhancement.

Video: What-If Scenarios with Gantt Drag-and-Drop Scheduling in PlanetTogether APS

In this video, you’ll see how PlanetTogether Advanced Planning & Scheduling (APS) combines Gantt-based drag-and-drop scheduling with powerful what-if scenarios so planners can quickly test changes and compare schedule options before committing them to the shop floor.

Instead of wrestling with spreadsheets or pen-and-paper charts, PlanetTogether lets you visually drag jobs on a Gantt chart or grid, instantly see how the sequence changes, and evaluate the impact on other operations, due dates, and bottleneck resources.

You’ll learn how planners can:

- Use drag-and-drop simplicity to resequence jobs directly on the Gantt timeline and close gaps in the schedule

- Reallocate work to alternative resources with visual indicators showing which machines can complete the job

- Run what-if scenarios to compare different sequences, resource assignments, and priorities side-by-side

- Combine the visual nature of Gantt scheduling with APS’s constraint logic so capacity, material availability, and capabilities are respected automatically

- Avoid the common disadvantages of drag-and-drop (lack of detail, complexity with lots of data, easy editing mistakes) by using APS to enforce rules and prevent impossible schedules

This video is ideal for production schedulers, planners, and operations managers who want to leverage Gantt drag-and-drop scheduling and what-if analysis to build more realistic, optimized production plans.

See the Before-and-After Impact of Drag-and-Drop Scheduling with APS

Drag-and-drop scheduling and Gantt views make it far easier to build and adjust production schedules than pen-and-paper or spreadsheets—but the real value comes when those visual tools are powered by an Advanced Planning & Scheduling (APS) engine that understands capacities, materials, and constraints.

Download our Before & After Scheduling Infographic to see how moving from manual or spreadsheet-based planning to visual drag-and-drop scheduling in PlanetTogether APS can help you:

- Replace reactive spreadsheet updates with a single Gantt view that shows jobs, resources, and constraints in real time

- Re-sequence and reassign jobs with simple drag-and-drop, while APS automatically checks capacity and material availability

- Quickly spot bottlenecks, material shortages, and idle gaps in the schedule so you can fix issues before they hit delivery

- Use what-if scenarios to compare alternative schedules and choose the best option instead of guessing

- Turn your existing ERP/MRP data into an efficient, visual production plan that takes your operation to the next level of efficiency

Share this infographic with your planning and operations teams as a quick visual demonstration of how Gantt + drag-and-drop + APS dramatically improves the way you schedule.