The Schedule as the Law of the Land

A production schedule is meant to function like law.

It establishes order. It defines priority. It tells the organization what happens first, what happens next, and what cannot be violated without consequence. When it works, people don’t debate it. They operate within it.

With many companies I've spoken with, that is not how the schedule is treated. It is written as if it were binding, but enforced as if it were optional. More guidelines to adhere to rather than a mandate - directional guidance rather than a concrete instruction set.

That disconnect starts with the assumptions baked into the schedule itself. It assumes equipment behaves consistently. That labor is available when needed. That quality release happens on time. That run rates are accurate and up to date. When those assumptions fail, the schedule doesn’t adapt easily. Instead, teams work around it. Overrides and rework follows - and everyone knows this is a schedulers favorite pastime.

This is not a failure of execution on the shop floor. It is a failure of how scheduling is positioned inside the planning stack. We’ve treated the schedule as a document to publish, use briefly, and then explain away once reality hits. It is rarely treated as a decision system that will continuously help you reconcile your production intent and actual execution.

Where Plans Lose Authority

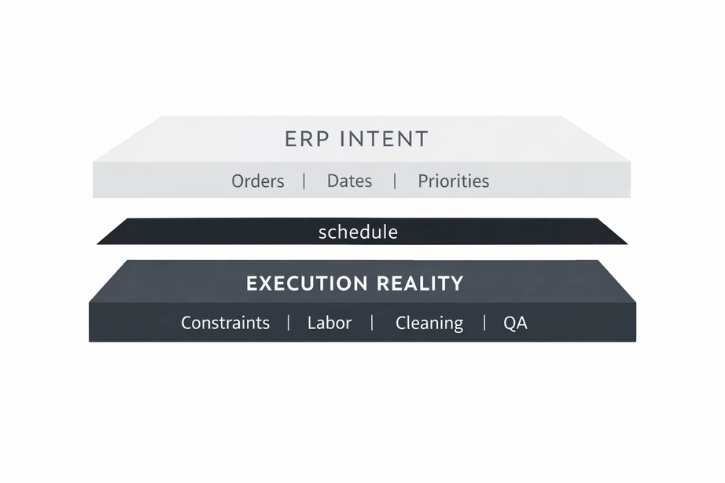

ERP systems are very good at expressing what the business wants to do. They balance demand, revenue targets, inventory policies, and customer priorities. By design, they assume resources can stretch to meet those goals. That optimism is useful at a commercial level, but dangerous when it flows downstream unchanged.

On the plant side, execution systems live in a different world. Equipment has limits. Cleaning takes time. Only certain people can run certain steps. Quality does not release product on a theoretical timestamp. None of this is abstract. It is enforced, minute by minute.

The gap between those two views is not a data gap. Most organizations already have access to machine status, labor availability, material constraints, and quality states. The problem is that the schedule rarely absorbs that information in a way that changes decisions.

Instead, it becomes a reference point that everyone quietly works around. Planners override it. Supervisors sequence locally if they believe they know a better way. Sales expedites orders. Inventory swells to protect service. The plan still exists, but no one expects it to hold.

Why Static Scheduling Fails Quietly

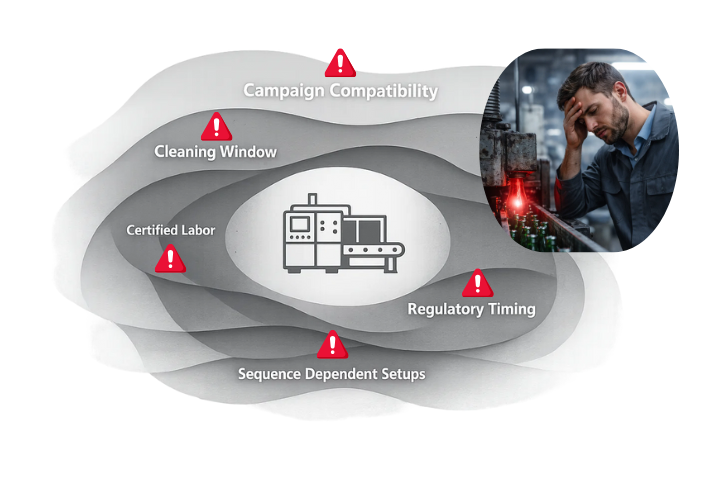

Most schedules don’t fail dramatically. They fail by a thousand small mismatches. A campaign runs longer than expected, pushing a cleaning window into the next shift. A qualified operator is reassigned. A batch clears production but waits on QA review. Each issue is manageable on its own. Collectively, they erode the schedule’s authority.

When scheduling is treated as a one-time calculation, the only options are manual intervention or waiting for the next planning cycle. Neither restores confidence. Manual fixes introduce inconsistency and politics. Waiting allows misalignment to spread.

The deeper issue is structural. The schedule can show problems, but it cannot renegotiate priorities under real constraints. It was never designed to.

Pillar 1: Scheduling That Responds to What Actually Happened

The first shift leaders need to make is moving away from static schedules toward closed-loop decision-making. Execution events invalidate plans constantly. Equipment goes down. A batch is placed on hold. Labor coverage changes. In most environments, these events trigger alerts, emails, or meetings. They rarely trigger a recalculation of what should run next across the full set of constraints.

A closed-loop scheduling approach treats execution feedback as a reason to re-decide, not just to inform. When something changes, the question isn’t “who needs to know,” it’s “what sequence still works.”

This does not mean chasing every disruption. It means the scheduling system is capable of re-evaluating trade-offs when reality diverges from assumptions and presenting feasible options instead of forcing teams to improvise.

Pillar 2: Capacity as Capability, Not Just Uptime

Many organizations claim to do finite scheduling, but their definition of capacity is narrow. Machines are either up or down. Lines are either available or not. Everything else is handled informally.

In practice, capacity is shaped by far more than equipment status. Campaign compatibility dictates sequence. Cleaning rules impose hard timing limits. Certain steps require certified personnel. Regulatory or audit windows constrain when work can occur.

When these factors are treated as notes instead of constraints, the schedule looks achievable until the moment it isn’t. At that point, execution teams absorb the impact, often by adding buffers elsewhere.

True finite scheduling requires encoding these realities directly into decision logic. Not as exceptions. Not as tribal knowledge. As conditions the schedule must respect.

Where Intent Meets Execution Decisions

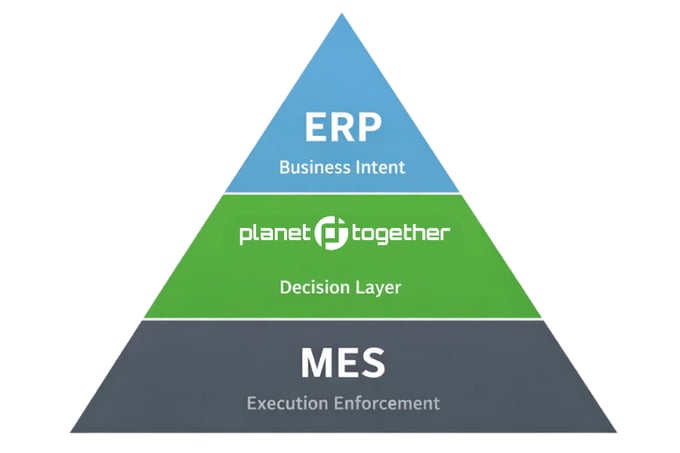

This is where an Advanced Planning and Scheduling system earns its role.

PlanetTogether operates alongside MES within the ISA-95 Level 3 domain. It does not control machines and it does not replace ERP. Its role is to decide what is feasible next when business intent collides with operational reality.

ERP defines what the business wants to achieve. MES enforces how work is executed. PlanetTogether reconciles those views into a schedule that reflects real capability, real timing, and real trade-offs. That distinction gives leaders something they rarely have today: a plan they can defend.

Pillar 3: Scheduling That Accounts for Risk, Not Averages

Most schedules rely on standard run rates and nominal durations. Those numbers are often outdated the day they’re published.

Process behavior varies. Raw material characteristics change. Certain conditions extend cycle time or increase quality risk. QA release timing introduces uncertainty that completion timestamps cannot capture.

Ignoring this doesn’t simplify planning. It shifts risk downstream. Missed commitments are explained after the fact. Inventory is padded to compensate. Firefighting becomes normal.

A more mature approach treats duration and availability as conditional, not fixed. When known factors increase risk or extend processing time, the schedule adjusts before the miss occurs. Quality status becomes part of availability, not a separate conversation.

When Scheduling Loses Authority, and Why It’s Allowed to Happen

By this point, most organizations know their schedule isn’t holding. The more uncomfortable question is why they allow it to keep happening.

One reason is misuse of tools. APS is often positioned as a better way to visualize the plan rather than the system that governs decisions. When it functions as a checkpoint instead of an authority on sequencing and priority, overrides become routine and accountability fades.

Another is ambiguity. Leaders avoid drawing hard lines around constraints, hoping flexibility will preserve speed. The opposite happens. Every exception becomes a debate. Every change becomes political. The schedule loses any claim to consistency.

Leadership behavior plays a decisive role. If teams are rewarded for bypassing the plan through local heroics, the plan will never hold. Protecting the schedule means backing planners when they say no and insisting that trade-offs are accounted for.

Finally, organizations confuse disciplined recalculation with instability. A schedule that reflects reality will change more often, but with intent. When leaders fail to distinguish recalculation from churn, APS becomes reactive instead of stabilizing.

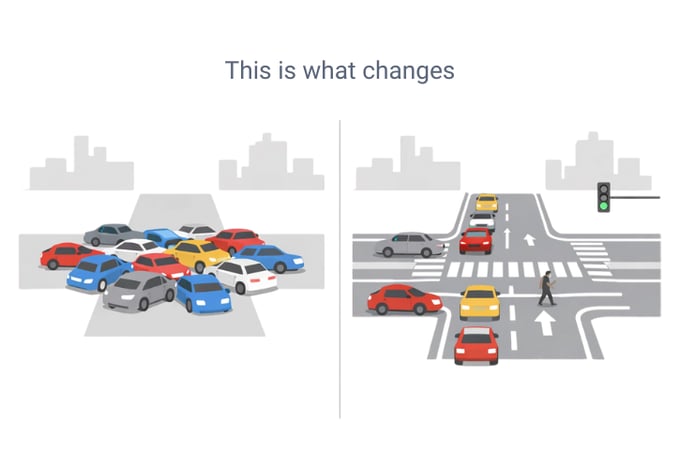

When the schedule does regain authority, behavior shifts.

Sales stops negotiating around the plan because it holds up. Operations spends less time explaining misses. Inventory buffers shrink intentionally instead of defensively. Trade-offs move into the open, where they can be evaluated early.

Scheduling authority is not restored through better math alone. It is restored through governance.

From Better Schedules to Better Decisions

The problem most manufacturers face is not a lack of data or effort. It is a planning stack that asks schedules to do a job they were never designed to do.

Treating scheduling as a living decision system changes that. It restores the schedule’s role as a governing mechanism between the business and the factory.

If your schedule no longer carries authority, the issue isn’t execution. It’s the system making the decisions.

Is your plant ready for a schedule that stays credible?

When schedules lose credibility between ERP and MES, the root cause usually isn’t effort, it’s a lack of consistent constraint logic, clean planning data, and an operating rhythm that updates the schedule when reality changes. The next step is to pinpoint exactly where your current process breaks down so you can prioritize fixes and evaluate APS with clear requirements.

Use our APS Readiness Scorecard to:

- Assess whether your data and constraints support feasible schedules

- Identify gaps in capacity modeling, changeovers, and material readiness

- Evaluate how schedule changes flow between planning and execution

- Establish governance for freeze windows, exceptions, and ownership

- Build a practical roadmap before selecting or expanding APS