Production schedulers play a pivotal role in ensuring that the right products are manufactured at the right time and in the right quantities . The healthcare industry faces unique challenges, especially during peak demand periods. Efficiently managing production during these times is crucial, as it can mean the difference between saving lives and falling short of critical medical supplies.

In this blog, we will explore the complexities of capacity forecasting and planning for peak demand periods in a medical manufacturing facility.

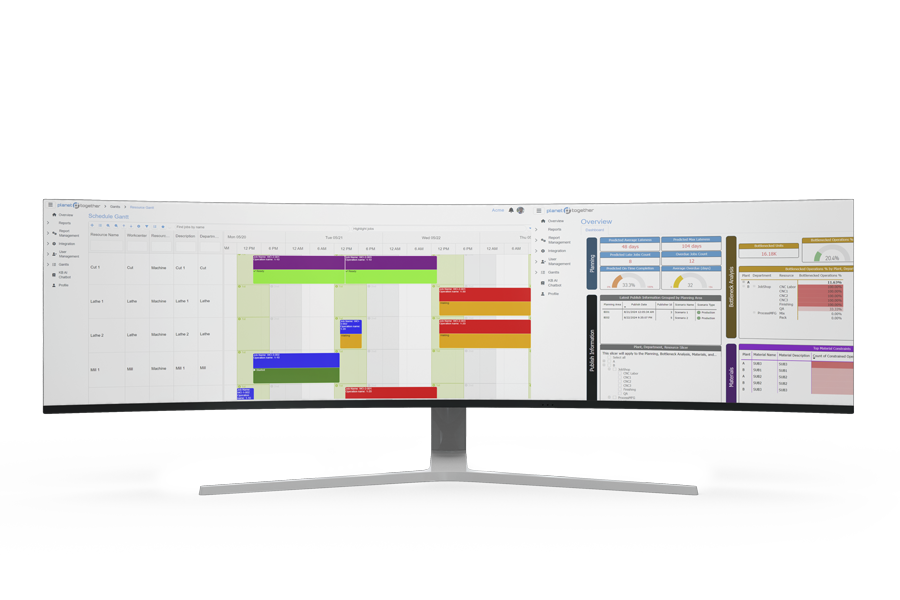

We will also discuss the integration of advanced planning and scheduling tools like PlanetTogether with popular Enterprise Resource Planning (ERP), Supply Chain Management (SCM), and Manufacturing Execution Systems (MES) software such as SAP, Oracle, Microsoft, Kinaxis, and Aveva.

But First... What Is Capacity Planning?

Capacity planning is the process of determining an organization's ability to meet its production or service delivery requirements in the most efficient and cost-effective manner. It involves forecasting future demand for products or services and ensuring that the organization has the necessary resources, such as personnel, equipment, facilities, and technology, to meet that demand. The goal of capacity planning is to strike a balance between resources and demand, avoiding underutilization or overutilization of resources.

The Importance of Peak Demand Capacity Planning

Meeting Regulatory Standards

One of the primary responsibilities of medical manufacturing facilities is to adhere to stringent regulatory standards, such as those set by the FDA (Food and Drug Administration) in the United States. Failing to meet these standards can have severe consequences, including product recalls and legal actions. Effective capacity planning is vital to ensure that all products are manufactured in compliance with these regulations.

Ensuring Product Availability

During peak demand periods, the need for medical supplies can spike significantly. This is often due to unforeseen events such as a disease outbreak or natural disasters. Efficient capacity planning ensures that the facility can meet this increased demand promptly and efficiently, helping to prevent shortages and keep essential medical products readily available.

Minimizing Costs

Optimizing production capacity is not only about meeting demand but also about managing costs effectively. Excess capacity leads to higher production costs, while insufficient capacity can result in expensive expedited orders and lost sales. Capacity forecasting and planning can help find the right balance, reducing production costs while maintaining high service levels.

Integration with Advanced Planning and Scheduling Tools

To meet the demands of the modern medical manufacturing industry, many facilities have turned to advanced planning and scheduling tools. Among the most popular are PlanetTogether, SAP, Oracle, Microsoft, Kinaxis, Aveva, and other ERP, SCM, and MES systems. These tools offer a wide range of capabilities, including real-time data analysis, decision support, and automation.

PlanetTogether: The Ultimate Scheduling Solution

PlanetTogether is a powerful production planning and scheduling software designed to optimize manufacturing operations. Its advanced features include:

-

Capacity Planning:

PlanetTogether can help you visualize your facility's capacity and ensure that you are prepared for peak demand periods. By considering machine and labor capacities, it can determine if your facility can meet the increased demand or if additional resources are needed.

-

Scenario Analysis:

-

The software allows you to run various scenarios to determine the best course of action during peak demand periods. This may involve adjusting schedules, allocating additional resources, or even outsourcing specific production steps.

-

Real-time Monitoring:

-

PlanetTogether provides real-time visibility into your production processes. This ensures that you can make rapid adjustments in response to changing circumstances, such as unexpected spikes in demand.

Integration with ERP, SCM, and MES Systems

For a seamless capacity planning and scheduling process, integration with ERP, SCM, and MES systems is crucial. Let's look at how this integration can benefit your medical manufacturing facility:

-

SAP:

-

Integration with SAP streamlines data flow and enhances decision-making. You can have a real-time connection between your production scheduling and resource planning.

-

Oracle:

-

Oracle ERP systems offer robust financial and resource planning capabilities. Integrating with PlanetTogether ensures that production scheduling aligns with these plans.

-

Microsoft Dynamics:

-

Microsoft's suite of tools can benefit your medical manufacturing facility. Integration ensures seamless communication between your scheduling and other operational functions.

-

Kinaxis:

-

Kinaxis RapidResponse provides end-to-end supply chain planning and response management. Integrating with PlanetTogether helps create a holistic view of your operations.

-

Aveva:

-

Aveva MES provides real-time visibility and control over your manufacturing processes. Integrating with PlanetTogether ensures that your scheduling aligns with the actual shop floor activities.

Capacity Forecasting and Planning Best Practices

To effectively forecast and plan for peak demand periods, consider the following best practices:

Historical Data Analysis: Examine historical demand patterns to identify trends and potential seasonality. This data can serve as a basis for future forecasts.

Collaborative Planning: Engage with your sales, marketing, and procurement teams to gather insights on anticipated demand spikes. Collaborative planning can lead to more accurate forecasts.

Scalable Workforce: Ensure that your labor force is scalable during peak periods. This might involve hiring temporary workers or cross-training existing staff.

Safety Stock: Maintain safety stock levels for critical items to mitigate supply chain disruptions and uncertainties during peak demand.

Real-time Monitoring: Use advanced planning and scheduling tools like PlanetTogether to monitor production in real time and make agile adjustments as needed.

Capacity forecasting and planning for peak demand periods is a critical function in medical manufacturing. In this industry, precision, speed, and compliance are paramount. By integrating advanced planning and scheduling tools like PlanetTogether with ERP, SCM, and MES systems, production schedulers can navigate the complexities of peak demand with confidence.

Efficient capacity planning not only ensures that regulatory standards are met and products are readily available but also minimizes costs. The healthcare industry's reliance on medical manufacturing facilities has never been more apparent than during critical times like a pandemic. Hence, the importance of meticulous capacity planning and scheduling cannot be overstated.

As a production scheduler in the medical manufacturing field, your role is integral to saving lives, and by following best practices and utilizing advanced tools, you can help ensure that healthcare facilities have the supplies they need when they need them most.