What is Machine Shop Scheduling?

Machine shop scheduling refers to the process of planning and organizing the production activities within a machine shop or manufacturing facility. The primary goal of machine shop scheduling is to optimize the utilization of resources, such as machines, labor, and materials, to ensure efficient and timely production of goods.

What is Advanced Planning and Scheduling?

Advanced Planning and Scheduling (APS) is a category of software tools and systems designed to enhance and automate the planning and scheduling processes within manufacturing and production environments. APS systems go beyond basic scheduling functionalities and incorporate advanced algorithms, optimization techniques, and real-time data to help organizations improve their overall operational efficiency.

How are Machine Shop Scheduling and Advanced Planning and Scheduling (APS) related?

APS in machine shop scheduling offers optimized resource utilization, reduced lead times, and enhanced decision-making through advanced algorithms, simulation capabilities, and integration with ERP systems. These benefits lead to increased efficiency, faster production cycles, and improved customer satisfaction.

Implementing Advanced Planning and Scheduling (APS) in machine shop scheduling offers several benefits:

- Optimized Resource Utilization

- Reduced Lead Times and Improved On-Time Delivery

- Enhanced Decision-Making Through What-If Analysis

10 Best Practices - Machine Shop Scheduling

The machine shop scheduling best practices outlined align seamlessly with the core principles and functionalities of Advanced Planning and Scheduling (APS) systems. Let's explore how each best practice corresponds to the features of an APS system:

Seamless Connection with Resource Management Systems:

In the context of advanced planning and scheduling, achieving a seamless connection with various resource management systems is crucial. This integration facilitates real-time data exchange, enhancing decision-making processes.

High-level Planning Logic Integration:

An integral aspect of advanced planning and scheduling involves the automatic integration of high-level planning logic. This includes considerations of finite capacities, constraints, and variables, ensuring optimized job arrangements in relation to capacity.

Automatic Prioritization and "What If" Scenarios:

Within the framework of advanced planning and scheduling principles, automatic prioritization is a key feature, particularly for rush orders. The system allows for the simulation of "what if" scenarios, providing the flexibility to make quick adjustments for optimum productivity.

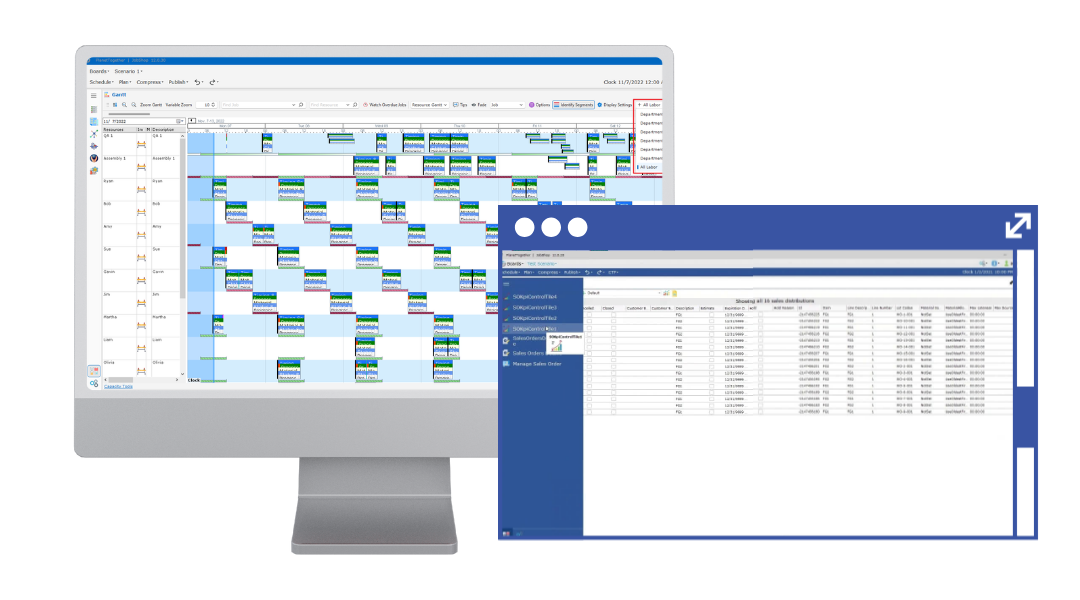

Clear, Visual Language:

Visual clarity plays a foundational role in advanced planning and scheduling systems. Utilizing clear, visual language, including color-coded warnings and symbols, enhances the ability to identify conflicts, bottlenecks, and understand the impact of new orders on the production plan.

Multi-dimensional Outlook:

Advanced planning and scheduling systems offer a multi-dimensional outlook, taking into account a wide array of variables beyond a one-dimensional visual system. This capability enables comprehensive and detailed planning.

Proactive Support of Planning Activities:

One of the strengths of advanced planning and scheduling is the provision of proactive support. The system is designed to immediately detect scheduling conflicts when alterations are made, allowing schedulers to address issues promptly for efficient production planning.

Delineation of Order Alterations and Impact:

In the context of advanced planning and scheduling, the system automatically adjusts successors and predecessors when order alterations occur. This ensures a clear delineation of changes and their impact on the production schedule.

Power to Manually Alter the Schedule:

Users benefit from the empowerment to manually alter schedules, including machine allocation, dates, and times. The drag-and-drop technique aligns with the interactive nature of the system, allowing for real-time adjustments.

Swift Capacity Changes:

Within advanced planning and scheduling, the system enables schedulers to swiftly change capacities. This includes inserting extra shifts, adjusting labor, or accommodating absent personnel. Such responsiveness is critical for adapting to changing production demands.

Actionable Method for Developing Scenarios:

Advanced planning and scheduling systems support the development of different production scenarios and strategies. This includes the ability to switch between production strategies like ASAP and JIT, offering flexibility to meet delivery dates while optimizing floor operations.

Advanced Planning and Scheduling systems serve as advanced tools that can be applied in the context of machine shop scheduling. They provide a more sophisticated and automated approach to the challenges of scheduling within a manufacturing environment, offering enhanced capabilities to meet the complex demands of modern production processes.

Ready to optimize your production? Take the next step towards efficiency and improved performance. Contact us today to schedule a personalized demo and discover how our Advanced Planning and Scheduling solutions can transform your machine shop. Let's elevate your production processes together!