Overall Equipment Effectiveness (OEE) was originally described as a central component of Total Productive Maintenance (TPM) in an effort to produce goods with zero defects and zero losses. The overall goal of TPM is to achieve the most optimal production process by increasing productivity, efficiency, and safety.

What Is Overall Equipment Effectiveness?

Overall Equipment Effectiveness (OEE) is a measure of how well a manufacturing operation is utilized compared to its full potential. It helps manufacturers identify areas of production that are actually efficient and productive, and which areas are in need of improvement.

The OEE value is represented as a percentage. A score of 100% means that you are utilizing your resources to their full extent. In other words, you are producing quality products, quickly, with little to no machine downtime.

Any value lower than 100% is considered an opportunity for improvement which is one of the main goals of total production maintenance. Utilizing OEE can be extremely beneficial to your operation and can identify losses, progress, and various methods to potentially improve productivity among the equipment. There are many advantages that will come when you calculate the Overall Equipment Effectiveness of your manufacturing operation.

Advantages of Overall Equipment Effectiveness (OEE)

Here are the advantages of utilizing overall equipment effectiveness (OEE):

1. Visualizing Performance

The most obvious advantage of calculating OEE is that you will be able to easily visualize the performance of your production facility. This is because Overall Equipment Effectiveness looks at production inefficiencies and losses in three areas: availability, performance, and quality. These values are then grouped into a single metric that shows the current production status and areas in need of improvement.

2. Production Insight

It is impossible to know the real state of your production operations without measuring it. Oftentimes, manufacturers will assume that their process efficiency is much higher than it really is. This is because you cannot manage or improve things that are not being measured. When you analyze your production performance and performance losses, you will have a better understanding of which areas of your production are working at peak efficiency, and which areas are in need of improvement.

3. Increase Competitiveness

The manufacturing market is highly competitive, with many producers and consumers influencing the products that are being produced. Manufacturers must strive to maintain a competitive advantage to increase their profits. Overall Equipment Effectiveness can help manufacturers increase their competitiveness by highlighting areas that are in need of improvement. As a result, manufacturing operations will be able to reduce the cost of production and deliver a product of high quality to their customers. By having a better value and quality than their competitors, manufacturers will maintain their competitive advantage in the market.

4. Reduce Machinery Cost

Understanding the actual performance of your machinery directly correlates to knowing whether the machine is working efficiently or not. It also preemptively identifies whether there are issues that may lead to the need for future repair and can help prevent major breakdowns from occurring. With Overall Equipment Effectiveness, you will be able to anticipate events that are extremely costly for manufacturing facilities, such as machine failures, and be able to plan preventative maintenance at strategic times. In addition, by optimizing your production, you will be able to reduce the time during which costly machines are sitting idle and waiting on predecessor operations to be completed.

5. Return on Investment (ROI)

Machinery and equipment represent large investments made by companies in order to achieve maximum return on investment. Overall Equipment Effectiveness will first help manufacturers identify the best area to invest funds in. In addition, OEE calculations will help the facility compare performance before and after the new piece of equipment was added, as well as ensure that the new machine is utilized to its full potential. Operators are able to prove the amount of financial value of these investments, conducted through measurable data provided by overall equipment effectiveness (OEE).

How to Calculate Overall Equipment Effectiveness (OEE)

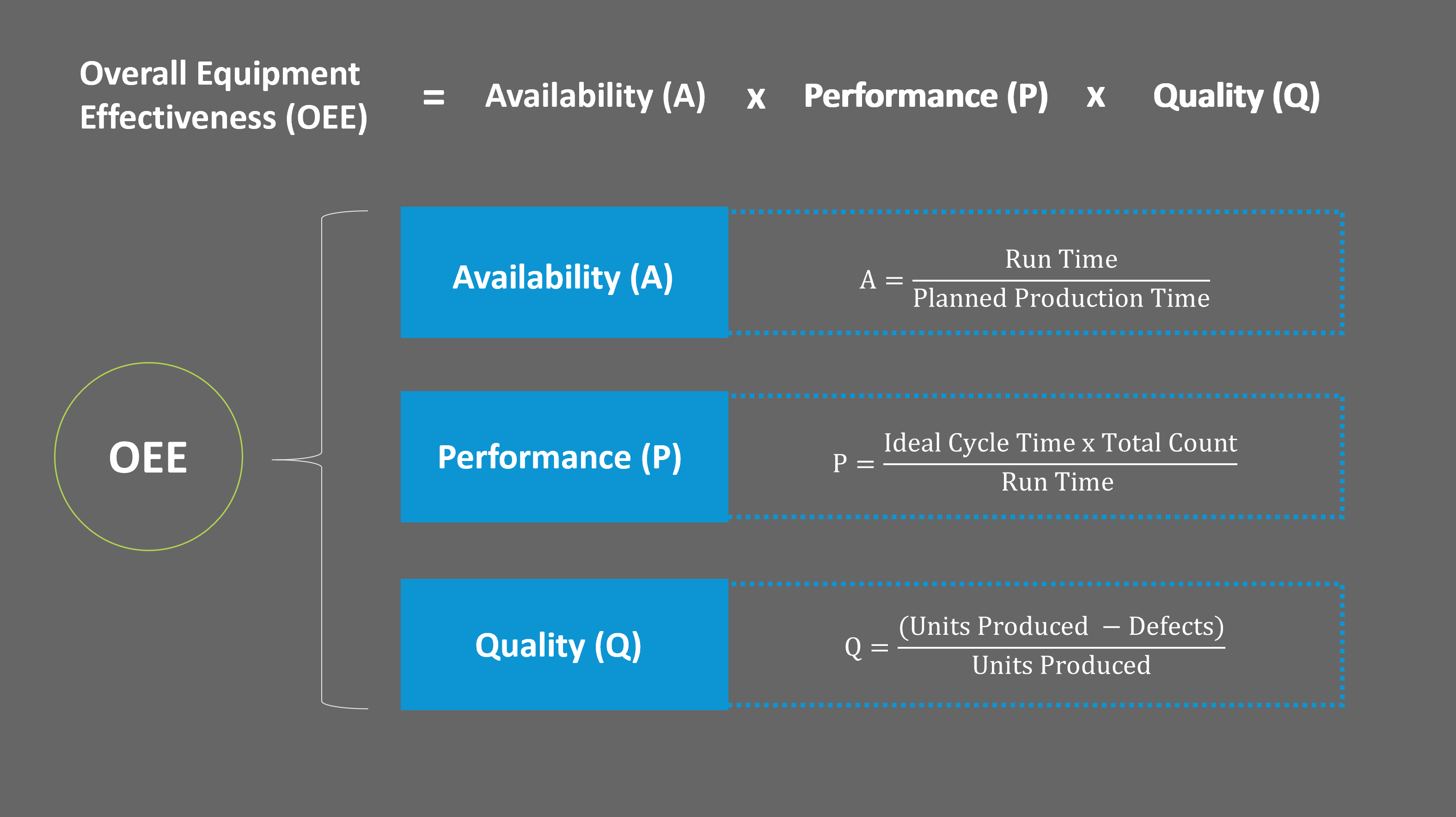

The formula to calculate Overall Equipment Effectiveness is as follows:

OEE = Availability (A) x Performance (P) X Quality (Q)

The three components - availability, performance, and quality - represent areas that suffer the biggest losses. Poor product quality with many defects, a slow performance rate, and lots of stopping and starting makes for an unproductive system. Each component of the equation has its own definition and calculation as well:

- Availability (A)

- Availability (A) = Run Time / Planned Production Time

- This component takes into account all of the events that prevent production from running. This can include planned stops such as changeovers and setup time, or unplanned stops such as machine breakdowns.

- Performance (P)

- Performance (P) = (Ideal Cycle Time x Total Count) / Run Time

- This component takes into account all of the events that cause manufacturing to have a slower run rate than the maximum possible run rate.

- Quality (Q)

- Quality (Q) = (Units Produced - Defects) / Units Produced

- This component accounts for all of the manufactured goods that don’t meet the quality standards desired or are in need of a rework.

Calculating Overall Equipment Effectiveness will allow you to identify areas in your production facility that are causing you to be inefficient. Once OEE is calculated, Advanced Planning and Scheduling (APS) softwares can help you optimize your production schedule to minimize downtime and increase output.

Another PlanetTogether APS benefit is the ability to integrate preventative maintenance schedules with manufacturing schedules. Commitments cannot be met without maximizing Overall Equipment Effectiveness (OEE). Having the freedom to block out time for preventative maintenance before the schedule is filled with orders increases our uptime and capacity.

GARY BISHOP, DIRECTOR OF MANUFACTURING OPERATIONS, SUMITOMO ELECTRIC LIGHTWAVE

Advanced Planning and Scheduling (APS) Software

Advanced Planning and Scheduling Softwares have become a must for modern-day manufacturing operations as customer demand for increased product assortment, fast delivery, and downward cost pressures become prevalent. These systems help planners save time while providing greater agility in updating ever-changing priorities, production schedules, and inventory plans. APS Systems can be quickly integrated with an ERP/MRP software to fill the gaps where these systems lack planning and scheduling flexibility, accuracy, and efficiency.

With PlanetTogether APS you can:

- Create optimized schedules that balance production efficiency and delivery performance

- Maximize throughput on bottleneck resources to increase revenue

- Synchronize supply with demand to reduce inventories

- Provide company-wide visibility to resource capacity

- Enable scenario data-driven decision making

The implementation of an Advanced Planning and Scheduling (APS) Software will take your manufacturing operations to the next level of production efficiency by taking advantage of the operational data you already possess in your ERP system. APS is a step in the right direction of efficiency and lean manufacturing production enhancement. Try out a free trial or demo!

Related Lean Video

APS Resources