What's Advanced Planning and Scheduling (APS)?

Manufacturing has always been an essential part of our economy, and the use of technology has made it more efficient and productive than ever before. One of the most significant advancements in manufacturing technology has been the development of Advanced Planning and Scheduling (APS) systems. An APS system is a software tool that enables manufacturers to plan and schedule their production processes more effectively. In this blog post, we will explore the five benefits of using an APS system in your manufacturing facility.

Advanced Planning & Scheduling (APS) software enables fast and flexible capacity planning, production scheduling, and MRP (material requirements planning) connected to your existing ERP system.

It goes beyond traditional planning methods by incorporating real-time data, complex algorithms, and optimization techniques to make decisions that align with organizational goals and objectives.

How Advanced Planning and Scheduling Transforms Manufacturing Efficiency

Example: Consider a manufacturing company that produces electronic devices. Without APS, the production planning and scheduling might be done manually, relying on historical data and basic forecasting methods. This could lead to inefficiencies, such as overproduction, underutilization of resources, and delays in fulfilling customer orders.

Now, with the implementation of Advanced Planning and Scheduling, the company can utilize a comprehensive software solution. This software takes into account various factors like current inventory levels, production capacity, supplier lead times, and customer demand patterns. Using this information, the APS system generates optimized production schedules, ensuring that resources are allocated efficiently, production targets are met, and customer orders are delivered on time.

In this example, APS helps the company proactively address challenges by providing a dynamic and data-driven approach to planning and scheduling. It not only considers current conditions but also adapts quickly to changes in demand, supply chain disruptions, or other variables that can impact production. This leads to a more agile and responsive manufacturing process, ultimately improving overall operational performance and customer satisfaction.

Benefit #1: Improved Production Planning

An APS system can significantly improve production planning in a manufacturing facility. By analyzing historical data and real-time information, the system can forecast demand accurately and create production schedules that optimize resource utilization. This level of planning helps manufacturers to avoid stockouts, reduce lead times, and improve on-time delivery rates. APS systems also make it possible to manage the capacity of the manufacturing facility effectively, ensuring that production schedules are achievable and aligned with the overall business objectives.

Benefit #2: Increased Production Efficiency

Production efficiency is a key driver of profitability in manufacturing. An APS system helps to increase production efficiency by reducing setup times, minimizing changeovers, and improving machine utilization rates. The system can also optimize the sequence of operations to minimize production bottlenecks, reduce idle time, and improve overall equipment effectiveness (OEE). With an APS system in place, manufacturers can achieve higher production output without compromising on quality or safety.

Benefit #3: Improved Supply Chain Coordination

Manufacturing is a complex process that involves multiple suppliers, materials, and processes. An APS system helps to improve supply chain coordination by providing manufacturers with real-time visibility into their supply chain. The system can help to optimize inventory levels, track the movement of materials, and reduce lead times. By integrating with other supply chain management systems, an APS system can enable manufacturers to collaborate more effectively with their suppliers, improve supplier performance, and reduce supply chain risk.

Benefit #4: Enhanced Customer Service

In manufacturing, customer service is critical to success. An APS system can help manufacturers to deliver better customer service by improving on-time delivery rates and reducing lead times. The system can also enable manufacturers to respond more effectively to changes in customer demand, ensuring that they can deliver the products their customers need, when they need them. By providing real-time visibility into production schedules, an APS system can help manufacturers to communicate more effectively with their customers, enhancing trust and loyalty.

Benefit #5: Improved Financial Performance

An APS system can help manufacturers to improve their financial performance in several ways. By reducing inventory levels and improving production efficiency, the system can help to reduce the cost of goods sold (COGS) and increase gross margins. The system can also enable manufacturers to optimize their production schedules, reducing overtime costs and improving resource utilization. By providing real-time visibility into the production process, an APS system can help manufacturers to identify and eliminate waste, reducing operating expenses and improving overall profitability.

An APS system is a powerful tool that can help manufacturers to improve production planning, increase production efficiency, improve supply chain coordination, enhance customer service, and improve financial performance. By leveraging the power of data analytics and real-time information, an APS system can enable manufacturers to optimize their production processes, reduce costs, and improve profitability. If you are looking to improve your manufacturing operations, investing in an APS system is a smart decision that will pay off in the long run.

Advanced Planning and Scheduling will lead you to:

• Grow sales with quicker production lead-times.

• Cut inventory by aligning manufacturing with demand.

• Reduce unit costs with more efficient production runs.

• Improve decisions with capacity visibility & scenarios and Analytics

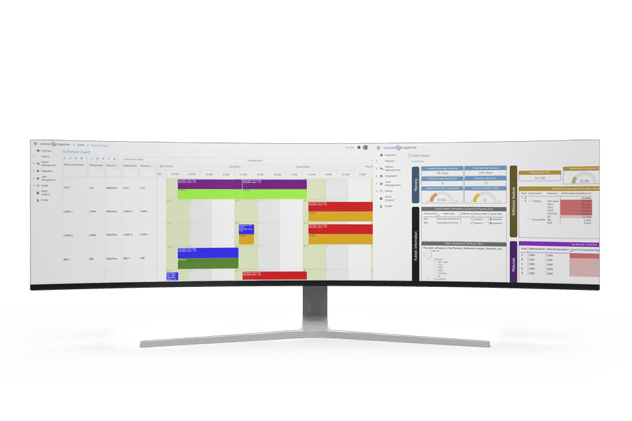

Ready to Transform Your Manufacturing Efficiency?

Discover how PlanetTogether APS can help you optimize production, improve resource utilization, and enhance supply chain coordination. Request a demo today to see the impact of advanced planning and scheduling in action!