AI-Driven Material Flow

The role of a Production Scheduler is indispensable in packaging manufacturing. The orchestration of material flow, ensuring seamless operations, and meeting customer demands require a delicate balance of foresight and adaptability. In recent years, the integration of Artificial Intelligence (AI) into production scheduling has emerged as a game-changer, revolutionizing the way packaging facilities manage their operations.

In this blog, we'll look into the transformative power of AI-driven material flow in packaging manufacturing, exploring its benefits, challenges, and the integration possibilities with leading ERP, SCM, and MES systems like SAP, Oracle, Microsoft, Kinaxis, Aveva, and others, particularly through the lens of integration with PlanetTogether.

The Evolution of Production Scheduling: From Manual to AI-Driven

Traditionally, production scheduling in packaging manufacturing heavily relied on manual processes, spreadsheet-based calculations, and heuristic decision-making. While effective to some extent, these methods were prone to errors, lacked real-time adaptability, and struggled to optimize complex material flows.

The advent of AI technologies has reshaped this landscape. AI-driven production scheduling leverages advanced algorithms, machine learning, and predictive analytics to optimize material flow, streamline operations, and enhance decision-making. By analyzing vast datasets, AI can predict demand fluctuations, identify bottlenecks, and recommend optimal schedules with unprecedented accuracy and efficiency.

Benefits of AI-Driven Material Flow

The integration of AI into production scheduling offers a myriad of benefits for packaging manufacturing facilities:

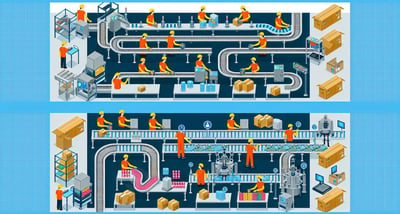

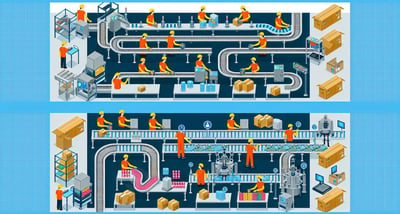

Optimized Resource Utilization: AI algorithms can dynamically allocate resources such as machines, labor, and raw materials based on real-time demand and capacity constraints, maximizing utilization and minimizing idle time.

Improved Efficiency: By automating scheduling processes and considering multiple variables simultaneously, AI-driven systems can generate schedules that minimize setup times, reduce changeover costs, and optimize production sequences.

Enhanced Flexibility: AI enables agile and adaptive scheduling, allowing facilities to respond rapidly to changing market demands, production disruptions, and supply chain fluctuations.

Reduced Lead Times: With AI's ability to anticipate demand patterns and optimize production schedules accordingly, packaging manufacturers can significantly reduce lead times, improving customer satisfaction and market competitiveness.

Cost Savings: By minimizing waste, reducing inventory levels, and optimizing resource utilization, AI-driven material flow can lead to substantial cost savings across the entire production process.

Challenges and Considerations

While the benefits of AI-driven material flow are undeniable, implementing and integrating these technologies into existing manufacturing ecosystems come with their own set of challenges:

Data Integration and Quality: Effective AI relies on access to accurate and comprehensive data from various sources such as ERP, SCM, MES systems, and production equipment. Ensuring data integrity, consistency, and compatibility across these systems is essential for successful integration.

Change Management: Transitioning from traditional scheduling methods to AI-driven approaches requires organizational buy-in, cultural shift, and skill development among production teams. Change management efforts are crucial to mitigate resistance and foster acceptance of new technologies.

Complexity and Scalability: Packaging manufacturing operations are inherently complex, with numerous interconnected processes and variables. AI-driven material flow solutions must be capable of handling this complexity while remaining scalable to accommodate future growth and expansion.

Integration with Existing Systems: Seamless integration with existing ERP, SCM, and MES systems is essential for the success of AI-driven material flow initiatives. Compatibility, interoperability, and data synchronization between these systems and AI platforms such as PlanetTogether are critical considerations.

Integration Possibilities with Leading ERP, SCM, and MES Systems

The integration of AI-driven material flow solutions like PlanetTogether with leading ERP, SCM, and MES systems such as SAP, Oracle, Microsoft, Kinaxis, Aveva, and others holds immense potential for packaging manufacturers:

SAP Integration: SAP's comprehensive suite of ERP and supply chain management solutions can provide valuable data insights and business intelligence, which can be leveraged by AI-driven scheduling platforms like PlanetTogether to optimize material flow and production schedules.

Oracle Integration: Oracle's robust manufacturing and supply chain management software can seamlessly integrate with AI-driven scheduling systems, enabling real-time visibility into production processes, inventory levels, and demand forecasts for enhanced decision-making.

Microsoft Integration: Microsoft's Dynamics 365 suite offers a range of ERP and CRM applications that can be integrated with AI-driven scheduling solutions to streamline production operations, improve collaboration, and drive efficiency across the supply chain.

Kinaxis Integration: Kinaxis' RapidResponse platform provides advanced supply chain planning capabilities, which, when integrated with AI-driven scheduling tools, can enable end-to-end visibility, demand synchronization, and scenario analysis for optimized material flow.

Aveva Integration: Aveva's Manufacturing Execution System (MES) solutions offer real-time production monitoring, control, and optimization functionalities, which can complement AI-driven scheduling platforms like PlanetTogether to achieve greater operational efficiency and agility.

In packaging manufacturing, AI-driven material flow represents a paradigm shift in production scheduling, offering unprecedented levels of efficiency, agility, and optimization. By leveraging advanced AI algorithms, predictive analytics, and integration with leading ERP, SCM, and MES systems, packaging facilities can unlock new levels of productivity, cost-effectiveness, and customer satisfaction.

As a Production Scheduler, embracing AI-driven material flow technologies is not just a choice but an imperative to stay competitive in an increasingly complex and demanding market landscape. By harnessing the power of AI, you can transform your role from a mere orchestrator of schedules to a strategic enabler of operational excellence and business success in the dynamic world of packaging manufacturing.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.