AI-Optimized Inventory Allocation Strategies

In the realm of chemical manufacturing, the management of inventory is a critical component of operational success. Efficient inventory allocation can significantly impact a company's bottom line, ensuring optimal resource utilization, timely production, and customer satisfaction. With the advent of artificial intelligence (AI) technologies, manufacturers now have unprecedented opportunities to enhance their inventory allocation strategies.

In this blog post, we look into the realm of AI-optimized inventory allocation strategies, exploring how chemical manufacturers can leverage advanced technologies to streamline operations and drive profitability.

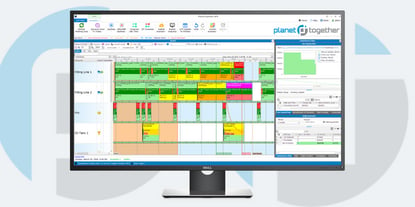

Furthermore, we'll discuss the integration between PlanetTogether, a leading advanced planning and scheduling (APS) software, and prominent Enterprise Resource Planning (ERP), Supply Chain Management (SCM), and Manufacturing Execution Systems (MES) such as SAP, Oracle, Microsoft, Kinaxis, and Aveva, illustrating how this integration can elevate inventory allocation to new heights of efficiency.

Understanding the Challenges

Chemical manufacturing is inherently complex, characterized by diverse product lines, stringent regulatory requirements, fluctuating market demands, and intricate supply chains. These complexities pose significant challenges to inventory management, often leading to issues such as overstocking, stockouts, excessive lead times, and suboptimal resource utilization.

Traditional inventory management approaches, reliant on manual forecasting and heuristic decision-making, often struggle to cope with the dynamic nature of the chemical industry, resulting in inefficiencies and missed opportunities.

The Role of AI in Inventory Allocation

Artificial intelligence offers a transformative solution to the challenges faced by chemical manufacturers in inventory allocation. By harnessing the power of machine learning algorithms, predictive analytics, and optimization techniques, AI systems can analyze vast datasets, identify patterns, and generate actionable insights in real-time. This enables manufacturers to make data-driven decisions, optimize inventory levels, mitigate risks, and respond swiftly to market fluctuations.

Key Components of AI-Optimized Inventory Allocation

Demand Forecasting: Accurate demand forecasting forms the foundation of effective inventory allocation. AI algorithms can analyze historical sales data, market trends, seasonal variations, and other relevant factors to generate precise demand forecasts. By anticipating future demand patterns, manufacturers can optimize inventory levels and minimize the likelihood of stockouts or excess inventory.

Dynamic Inventory Optimization: Traditional inventory management systems often rely on static reorder points and fixed lead times, leading to suboptimal inventory levels. AI-powered inventory optimization solutions continuously monitor demand fluctuations, supply chain dynamics, production capacities, and other variables to dynamically adjust inventory levels in real-time. This ensures that inventory is allocated efficiently, balancing the trade-offs between carrying costs and stockout risks.

Supply Chain Visibility: Effective inventory allocation requires comprehensive visibility into the entire supply chain, from raw material procurement to finished product distribution. AI technologies enable real-time monitoring of inventory levels, production schedules, transportation logistics, and supplier performance, allowing manufacturers to proactively identify bottlenecks, mitigate disruptions, and optimize inventory flow across the supply chain.

Risk Management: The chemical industry is susceptible to various risks, including supply chain disruptions, regulatory changes, and market volatility. AI-powered risk management solutions can assess the impact of potential risks on inventory levels and develop contingency plans to mitigate their effects. By proactively identifying and addressing risks, manufacturers can minimize inventory-related losses and maintain operational resilience.

Integration with PlanetTogether and ERP/SCM/MES Systems

The integration between PlanetTogether, a leading APS solution, and prominent ERP, SCM, and MES systems such as SAP, Oracle, Microsoft, Kinaxis, and Aveva, is instrumental in realizing AI-optimized inventory allocation strategies in chemical manufacturing facilities. This integration enables seamless data exchange and interoperability between planning, execution, and control systems, facilitating end-to-end visibility and decision-making.

Real-time Data Synchronization: Integration between PlanetTogether and ERP/SCM/MES systems ensures that inventory data, production schedules, resource capacities, and other relevant information are synchronized in real-time. This enables AI algorithms to access up-to-date data for demand forecasting, inventory optimization, and production planning, enhancing the accuracy and reliability of decision-making processes.

Unified Planning and Execution: By integrating APS capabilities with ERP, SCM, and MES systems, manufacturers can achieve a unified approach to planning and execution. Production plans generated by PlanetTogether can be seamlessly translated into actionable tasks within MES systems, ensuring alignment between production schedules, inventory targets, and resource allocations. This integration streamlines workflows, minimizes manual intervention, and enhances operational efficiency.

Scenario Analysis and Optimization: The integration between PlanetTogether and ERP/SCM/MES systems enables scenario analysis and optimization, allowing manufacturers to evaluate the impact of different inventory allocation strategies on key performance indicators (KPIs) such as cost, service levels, and lead times. By simulating various scenarios and identifying the optimal course of action, manufacturers can make informed decisions to maximize efficiency and profitability.

AI-optimized inventory allocation strategies hold immense potential for enhancing operational efficiency, reducing costs, and improving customer satisfaction in chemical manufacturing facilities. By leveraging advanced technologies such as machine learning, predictive analytics, and optimization algorithms, manufacturers can overcome the challenges of inventory management and realize significant business benefits.

Furthermore, integration between advanced planning and scheduling (APS) solutions like PlanetTogether and ERP/SCM/MES systems such as SAP, Oracle, Microsoft, Kinaxis, and Aveva is essential for unlocking the full potential of AI-powered inventory allocation. By enabling seamless data exchange, unified planning, and scenario analysis, this integration empowers manufacturers to make informed decisions and achieve competitive advantage in today's dynamic marketplace.

As chemical manufacturers continue to embrace digital transformation, AI-optimized inventory allocation will undoubtedly play a pivotal role in shaping the future of the industry. Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.