Advanced Planning and Scheduling and Enterprise Resource Planning

Any manufacturing company looking to improve their operation’s efficiency and output should consider combining the benefits of an Advanced Planning and Scheduling (APS) system with an Enterprise Resource Planning (ERP) system. By combining these two types of systems, manufacturers will be able to make the right decisions for their company to maximize their profits.

What is an APS System?

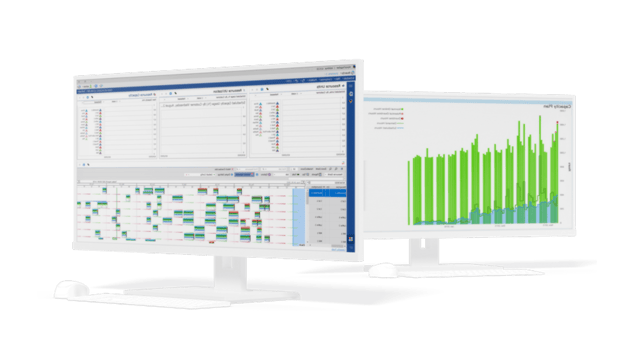

Advanced Planning and Scheduling systems such as the one offered by PlanetTogether allows for fast and flexible capacity planning, production scheduling, and materials requirement planning. With an APS system, you are able to concurrently plan and schedule your production which will allow you to minimize costs, maximize production, and increase profits. Companies considering an APS system should also consider its business counterpart: the Enterprise Resource Planning system.

What is an ERP System?

According to online tech dictionary Webopedia, an ERP is “a business process management system that allows an organization to use a system of integrated applications to manage and automate many back-office functions related to technology, services, and human resources.”

Essentially, ERP software combines all of the facets of a business operation in one place—inclusive of (but not limited to) product planning, development, manufacturing, sales, and marketing functions.

Why do I need an

Advanced Planning and Scheduling

(APS)?

The main problem with ERP software is that, despite its multitude of functions, it lacks the strategic decision-making functions that an Advanced Planning and Scheduling system has.

According to software advisory firm Technology Evaluation Centers (TEC), “an APS system can be used to better understand what needs to be planned and scheduled for optimal operations. These applications have different objectives and the results are based on how they are implemented, integrated, and used.”

An APS system allows a business to figure out and compensate for changes in production in real-time. With these types of softwares, ‘What-If’ analyses can be performed to see the impact an order change will have on customer orders. These systems can also calculate the best solutions for a company based on material, capacity, and logistical constraints.

In addition, an Advanced Planning and Scheduling application can configure long and short-term planning brackets. It can perform what-if scenarios, which in turn help businesses understand the most efficient manner of dealing with change without inflicting extra cost.

The power of the pair

Though an ERP and an APS system can be used independently, they work best when combined together. Without an ERP system, an APS application cannot perform rapid decision-making functions when changes are made in supply, demand, and manufacturing processes. For companies specializing in manufacturing, logistics, and distribution, a real-time analysis and simulation function offered by an APS system is necessary to keep costs low and efficiency high.

How it works

Advanced Planning and Scheduling systems can plan at the production line or machine levels, which gives users the ability to make changes and see the impact on customer orders before they happen. With this, planning can be easily rescheduled without running a new MRP (material requirement plan) within an ERP application.

When ERP and APS systems work together, the APS system takes into account time and manufacturing limitations simultaneously by using mathematical algorithms to give long and short-term production plans. They are then used by MRP to build out material requirement plans. Alternatively, some APS systems such as PlanetTogether have MRP embedded for an even more streamlined planning and analysis process.

“I recommend PlanetTogether APS because it has helped me save time as far as planning, not only one facility, but two facilities that are different and in many ways.“

Alma Ortiz

Corporate Master Scheduler, Snak-King

Logistically, an APS and an ERP just make sense together. If a company is looking to boost production time and speed, the partnership between an ERP’s central data system and an APS’s strategic planning ability is necessary. Those of you who already have an ERP system are already well on your way.

Advanced Planning and Scheduling (APS) Software

Advanced Planning and Scheduling Softwares have become a must for modern-day manufacturing operations as customer demand for increased product assortment, fast delivery, and downward cost pressures become prevalent. These systems help planners save time while providing greater agility in updating ever-changing priorities, production schedules, and inventory plans. APS Systems can be quickly integrated with an ERP/MRP software to fill the gaps where these systems lack planning and scheduling flexibility, accuracy, and efficiency.

With PlanetTogether APS you can:

- Create optimized schedules that balance production efficiency and delivery performance

- Maximize throughput on bottleneck resources to increase revenue

- Synchronize supply with demand to reduce inventories

- Provide company-wide visibility to resource capacity

- Enable scenario data-driven decision making

The implementation of an Advanced Planning and Scheduling (APS) Software will take your manufacturing operations to the next level of production efficiency by taking advantage of the operational data you already possess in your ERP system. APS is a step in the right direction of efficiency and lean manufacturing production enhancement. Try out a free trial or demo!

Related What-If Video

APS Resources