Automation of Repetitive Tasks in Production Planning

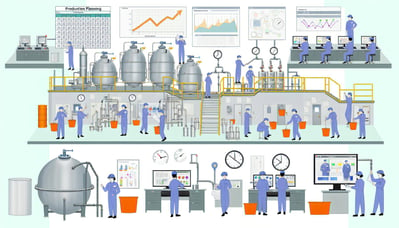

In today's chemical manufacturing industry, staying competitive requires continuous improvement in operational efficiency and production planning. Production planners play a pivotal role in ensuring smooth operations by creating optimized production schedules, managing resources, and ensuring on-time delivery of high-quality products. However, they often find themselves burdened with repetitive and time-consuming tasks that hinder their ability to focus on strategic decision-making.

The solution lies in automation, which can streamline repetitive tasks, reduce errors, and enhance overall productivity.

In this blog, we will explore the automation of repetitive tasks in production planning, with a specific focus on integrating PlanetTogether, a powerful production planning software, with leading ERP systems such as SAP, Oracle, Microsoft, Kinaxis and Aveva.

Repetitive Tasks in Production Planning

Production planning involves a multitude of tasks that are crucial for efficient operations. However, many of these tasks are repetitive and can be a drain on a production planner's time and energy. Some common challenges associated with repetitive tasks in production planning include:

Data Entry and Maintenance: Manually entering data, such as bill of materials (BOM), production schedules, and inventory levels, can be error-prone and time-consuming.

Forecasting: Repeatedly generating forecasts and adjusting them based on changing market conditions requires significant effort and may lead to inaccuracies.

Resource Allocation: Allocating resources, such as labor and equipment, to meet production demands is often a complex and repetitive process.

Inventory Management: Monitoring inventory levels, reorder points, and replenishment orders requires constant attention.

Communication: Coordinating with various departments and stakeholders can involve repetitive emails, calls, and meetings.

Automation can alleviate these challenges, allowing production planners to focus on more strategic aspects of their role.

The Benefits of Automation in Production Planning

Automation in production planning offers several benefits that can significantly enhance the efficiency of chemical manufacturing facilities:

Time Savings: By automating repetitive tasks like data entry, planners can save valuable time and redirect their efforts toward strategic planning and decision-making.

Reduced Errors: Automation minimizes the risk of human errors, leading to more accurate production schedules and inventory management.

Optimized Resource Allocation: Advanced planning algorithms help allocate resources efficiently, reducing production bottlenecks and idle time.

Improved Forecasting: Automation tools can analyze historical data and market trends to generate more accurate demand forecasts.

Enhanced Collaboration: Automated communication and data sharing between departments and systems improve collaboration and coordination.

PlanetTogether in Production Planning

PlanetTogether is a leading production planning and scheduling software that empowers manufacturers to optimize their production processes. It offers a wide range of features, including:

Advanced Planning Algorithms: PlanetTogether utilizes sophisticated algorithms to create optimal production schedules, considering constraints, resource availability, and production goals.

What-If Scenarios: Planners can simulate various scenarios to evaluate the impact of changes in demand, resource availability, or production capacity.

Real-Time Visibility: The software provides real-time visibility into production schedules, allowing planners to make informed decisions.

Integration Capabilities: PlanetTogether can integrate seamlessly with various ERP, SCM (Supply Chain Management), and MES (Manufacturing Execution System) solutions.

Integration of PlanetTogether with ERP, SCM, and MES Systems

To fully harness the power of automation in production planning, it's crucial to integrate PlanetTogether with ERP, SCM, and MES systems commonly used in the chemical manufacturing industry.

SAP Integration

SAP is a widely used ERP system in the manufacturing sector. Integrating PlanetTogether with SAP allows for seamless data exchange between production planning and other core business functions. Key benefits include:

Real-Time Data Sync: Production schedules and resource allocation data are synchronized in real-time with SAP, ensuring accurate inventory management and order processing.

Efficient Procurement: Automation ensures that procurement orders are generated at the right time, optimizing inventory levels and reducing carrying costs.

Oracle Integration

Oracle offers robust ERP solutions that streamline business operations. Integrating PlanetTogether with Oracle ERP offers the following advantages:

End-to-End Visibility: Planners can access real-time data on production schedules, resource utilization, and inventory levels directly from the Oracle system.

Comprehensive Reporting: Data integration enables the generation of comprehensive reports, facilitating better decision-making and compliance.

Microsoft Integration

Microsoft ERP solutions, such as Dynamics 365, are known for their flexibility and scalability. Integrating PlanetTogether with Microsoft ERP provides:

Seamless Collaboration: Planners and other stakeholders can collaborate on production plans using familiar Microsoft tools like Excel and Teams.

Scalable Solutions: The integration supports scalability, making it suitable for both small and large chemical manufacturing facilities.

Kinaxis Integration

Kinaxis RapidResponse is a popular SCM solution known for its rapid decision-making capabilities. Integrating PlanetTogether with Kinaxis offers:

Dynamic Planning: Real-time data exchange ensures that production plans are responsive to changing market conditions and supply chain disruptions.

Scenario Analysis: Planners can use Kinaxis's powerful scenario analysis tools in tandem with PlanetTogether's what-if scenarios for comprehensive planning.

Aveva Integration

Aveva MES is a widely adopted system for managing manufacturing operations. Integrating PlanetTogether with Aveva MES provides:

Efficient Manufacturing Execution: Automated scheduling and resource allocation improve manufacturing execution, reducing downtime and delays.

Quality Control: Integration allows for real-time quality control data to be incorporated into production planning, ensuring product quality.

Automation of repetitive tasks in production planning is a game-changer for chemical manufacturing facilities. By integrating PlanetTogether with leading ERP, SCM, and MES systems like SAP, Oracle, Microsoft, Kinaxis, Aveva, and others, production planners can streamline their workflows, reduce errors, and make data-driven decisions.

In an increasingly competitive market, staying ahead requires embracing automation and leveraging the full potential of modern planning and scheduling software.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

The future of chemical manufacturing belongs to those who can adapt and evolve their production planning processes to meet the demands of the digital age.