No matter how well operations are running in a manufacturing facility, bottlenecks can be found. As bottlenecks reduce the output of production, identifying and eliminating them should be a priority for manufacturers.

What is a Bottleneck?

A bottleneck represents a process or operation that has limited capacity and reduces the capacity of the entire production chain. In other words, bottlenecks are unable to process all of the work items quickly enough to get them to the next stage in operation without causing some sort of delay.

These delays in production cost money for as long as they are not resolved. They slow down the production process, hinder maximum potential and production, and slow down the facility. This is why it is essential to identify them early.

Identifying a Bottleneck Within Your Production Line

Identifying a bottleneck is half the battle, which is why there are a series of steps that can aid with bottleneck identification. A good place to start is to dive into your production process to measure operations that are taking the longest to figure out why some processes are taking too long. These steps to identify bottlenecks include the following:

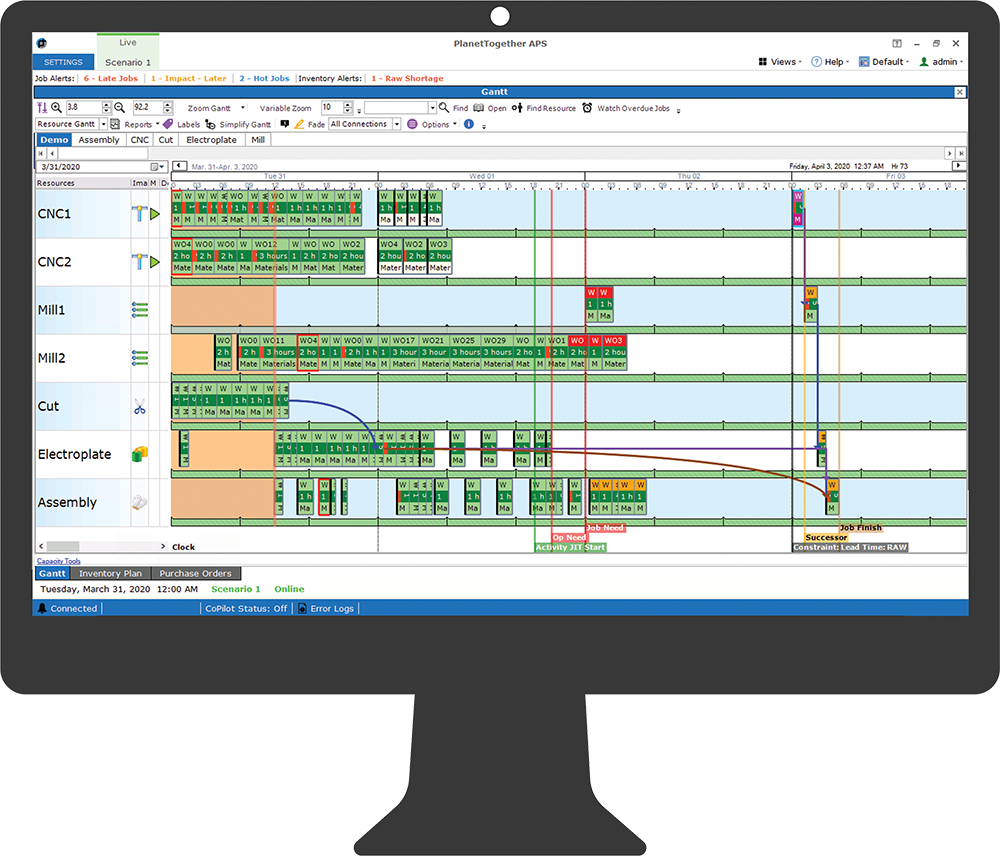

- Visualize – Visibility is key to identify bottlenecks. Keeping track of work through task cards on a Kanban board makes it relatively easy to see where work items are piling up or where there are strong signs of a problem. This will most likely be the bottleneck. Other visual production scheduling tools such as Gantt charts allow manufacturers to see all of their resources on one screen and provide a better understanding of how operations affect downstream operations.

- Map Queues and Activities – When separating queues and activities on the Kanban board, it is easier to visualize how much time work is sitting waiting in a queue prior to a certain activity. If you are seeing the queue grow faster than the activity stage processes work, then you have located your bottleneck.

- Measure Stage Cycle Time – It is also beneficial to measure your cycle time at every stage, considering that it allows you to build a cycle time heat map diagram. Just a glance at this diagram can reveal the stages where cards spend the most time. If workflow stages are queues as well, those are more than likely your bottlenecks.

After identifying your bottleneck, it is now time to take a look into how to eliminate or reduce it. This can be conducted in several ways.

How to Reduce Your Bottleneck Within Your Production Process

Reducing and eliminating bottlenecks within your production facility can be challenging, but can be done with proper guidance in the right direction. When seeking to contain a bottleneck, here are a few ways that you can reduce or contain your bottleneck:

- Process Work in Batches – Some operations are able to take less time if they are organized in similar work items in batches. With that being said, it is important to be cautious in the sense that the large batch sizes are always higher risk. Smaller batches are almost always better.

- Manage WIP Limits – If the work in progress (WIP) limits are rather liberal in the bottleneck, it may be worth considering lowering the WIP limit. It if doesn’t have a WIP limit, then maybe consider setting one.

- Never Leave It Idle – Idling can lead to a large percentage of downtime or loss of productivity, which is why the bottleneck process should always be loaded at full capacity. This will enable continuous production and time is never being wasted.

- Improve Quality – It is also important to ensure that work arrives in the very best form. Any quality issues can lead to reduced time and ultimately take longer, thus worsening your bottleneck.

A software that can aid with bottleneck reduction is PlanetTogether’s Advanced Planning and Scheduling (APS) Software. PlanetTogether is an absolute must for manufacturing facilities that are seeking to take their production to the next level in terms of operational efficiency. This software will increase the visibility you have within your manufacturing operations to allow you to easily identify bottlenecks and evaluate the outcome of various scenarios.

With PlanetTogether, we implement solutions to problems with confidence, and before constraints become a manufacturing issue.

GREGORY VAN LEIRSBURG, PRODUCTION SCHEDULER, STANDARD PROCESS SUPPLEMENTS

PlanetTogether’s Advanced Planning and Scheduling (APS) Software

Advanced Planning and Scheduling Softwares have become a must for modern-day manufacturing operations as customer demand for increased product assortment, fast delivery, and downward cost pressures become prevalent. These systems help planners save time while providing greater agility in updating ever-changing priorities, production schedules, and inventory plans. APS Systems can be quickly integrated with an ERP/MRP software to fill the gaps where these systems lack planning and scheduling flexibility, accuracy, and efficiency.

With PlanetTogether APS you can:

- Create optimized schedules that balance production efficiency and delivery performance

- Maximize throughput on bottleneck resources to increase revenue

- Synchronize supply with demand to reduce inventories

- Provide company-wide visibility to resource capacity

- Enable scenario data-driven decision making

The implementation of an Advanced Planning and Scheduling (APS) Software will take your manufacturing operations to the next level of production efficiency by taking advantage of the operational data you already possess in your ERP system. APS is a step in the right direction of efficiency and lean manufacturing production enhancement. Try out a free trial or demo!

Related What If Video

APS Resources