Driving Plant-Based Innovations: How Production Schedulers in Food and Beverage Manufacturing Can Optimize with APS Integration

The plant-based food movement has transformed from a niche dietary choice into a global industry powerhouse. With rising consumer demand for meat alternatives, dairy-free products, and sustainable food options, food and beverage manufacturers are under pressure to innovate quickly while maintaining operational efficiency. For production schedulers, this landscape introduces new complexities: how do you handle high-mix, low-volume production, uncertain demand patterns, short shelf lives, and evolving formulations—all while meeting sustainability goals and hitting delivery windows?

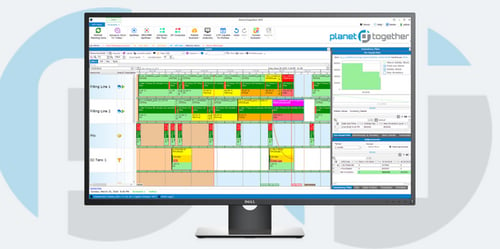

Enter Advanced Planning and Scheduling (APS) solutions like PlanetTogether, integrated seamlessly with enterprise systems such as SAP, Oracle, Microsoft, Kinaxis, or Aveva. This integration doesn’t just help production teams keep up—it helps them get ahead.

In this blog, we’ll explore how production schedulers in the food and beverage sector can harness APS tools to navigate the challenges and opportunities of plant-based innovation, turning complexity into competitive advantage.

The Rise of Plant-Based Products: Opportunities and Scheduling Challenges

Global sales of plant-based food products are projected to surpass $77 billion by 2025, fueled by changing consumer preferences, sustainability concerns, and health trends. While this surge brings enormous business opportunities, it also presents unique challenges on the production floor.

Production schedulers must manage:

Diverse SKUs — Plant-based lines often involve numerous formulations, flavors, and packaging formats to meet varied dietary needs and tastes.

Short production runs — Niche products may require smaller batches, increasing the frequency of changeovers and setup times.

Ingredient variability — Sourcing plant-based raw materials can be more volatile, especially when scaling up novel ingredients like pea protein, oat concentrate, or chickpea flour.

Shelf-life constraints — Many plant-based products, such as dairy-free yogurts or vegan cheeses, have short shelf lives, demanding tight synchronization between production and distribution.

Innovation pipelines — The pressure to launch new products quickly means recipes and packaging specifications may change mid-cycle.

Without smart scheduling, these factors can quickly lead to bottlenecks, waste, and missed delivery deadlines.

How PlanetTogether APS Empowers Food and Beverage Production Schedulers

PlanetTogether APS is designed to address the kind of complexity found in today’s food and beverage plants—especially those pioneering plant-based innovations. When integrated with major ERP systems like SAP, Oracle, Microsoft, Kinaxis, or Aveva, it creates a powerful, unified planning environment that links scheduling, materials, capacity, and demand.

Here’s how this integration transforms the production scheduler’s world:

Holistic Visibility Across Production and Supply Chains

By integrating PlanetTogether with your ERP, you unlock a single source of truth. Instead of juggling spreadsheets, emails, and disconnected software, production schedulers get a live, consolidated view of:

Current production schedules

Raw material availability

Inventory positions

Supplier lead times

Equipment capacity

For example, if a shipment of plant-based milk concentrate is delayed, the system immediately flags the affected production orders and recommends alternate scheduling scenarios. This level of integration ensures schedulers can respond proactively, minimizing disruptions.

Optimized Sequencing for High-Mix, Low-Volume Runs

Plant-based lines often switch between different flavors, allergen profiles, or organic/non-organic products. Each changeover adds downtime, cleaning requirements, and costs.

PlanetTogether’s intelligent sequencing engine analyzes:

Setup times

Cleaning constraints

Allergen changeovers

Product families

The system automatically generates optimized production sequences that reduce changeovers while maintaining compliance. This allows schedulers to maximize throughput even with small-batch, high-variation orders—a key advantage in the plant-based segment.

Real-Time Scenario Planning for Innovation Launches

Launching a new plant-based product? You’ll need to simulate how the introduction affects your current production schedule.

With PlanetTogether integrated into your ERP environment, production schedulers can run what-if scenarios to evaluate:

Capacity utilization impact

Resource bottlenecks

Material requirements

Delivery promise dates

This enables data-driven decision-making before scaling up, ensuring that innovation doesn’t derail core operations.

Synchronizing Production with Shelf Life and Demand

APS tools excel at finite scheduling, accounting for perishable goods’ shelf lives. For plant-based items, where freshness is often a competitive differentiator, this ensures production aligns tightly with demand forecasts and distribution timelines.

PlanetTogether’s integration with systems like SAP or Kinaxis enhances demand-supply alignment, allowing schedulers to prioritize production based on:

Expiration dates

Customer orders

Inventory turns

This reduces waste and ensures that products hit the market at peak freshness.

Supporting Sustainability and Efficiency Goals

Plant-based manufacturers often promote sustainability as part of their brand promise. Production schedulers play a critical role here, as efficient scheduling can reduce:

Energy consumption

Water use (especially critical in cleaning processes between runs)

Raw material waste

PlanetTogether’s advanced algorithms help identify energy-efficient scheduling windows, minimize unnecessary equipment cycling, and reduce rework. When paired with sustainability tracking modules within ERP systems, schedulers can directly contribute to corporate ESG (Environmental, Social, Governance) goals.

A Day in the Life: The Empowered Plant-Based Production Scheduler

Let’s bring this to life.

Imagine you’re a production scheduler at a plant that makes oat-based yogurt, vegan cheese, and almond milk. You receive an urgent directive: launch two new SKUs in time for an upcoming national retailer promotion.

With PlanetTogether APS integrated into your SAP system, you:

Pull live data on ingredient inventories and supplier lead times.

Simulate production runs to identify the most efficient sequence, minimizing allergen changeovers.

Adjust shift schedules and machine assignments based on predicted bottlenecks.

Coordinate with procurement to confirm material availability.

Confirm delivery dates and update the master schedule—all within the same integrated platform.

What used to take days or weeks of manual coordination now happens within hours. You’re not just keeping up—you’re driving the innovation engine.

Why Integration Is the Key to Success

Standalone scheduling tools can only take you so far. Without integration to ERP systems like SAP, Oracle, Microsoft, Kinaxis, or Aveva, schedulers risk working with outdated or incomplete data, leading to reactive firefighting rather than proactive planning.

By linking PlanetTogether APS with ERP, production schedulers gain:

End-to-end visibility

Data accuracy and consistency

Faster decision-making

Alignment between production, procurement, and sales

This integration turns scheduling into a strategic function, helping food and beverage manufacturers deliver on the full promise of plant-based innovation.

The future of food is undeniably plant-based, and production schedulers are at the heart of making this transformation possible. With the right tools, they can balance complexity, innovate with confidence, and ensure that sustainability and profitability go hand in hand.

PlanetTogether, integrated with leading ERP systems, empowers production teams to rise to this challenge—ensuring that every new recipe, every product launch, and every order run is optimized for today’s dynamic market.

As plant-based innovations continue to evolve, so too must the systems that support them. For production schedulers, investing in advanced planning and scheduling integration isn’t just a technology upgrade—it’s a strategic imperative.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.