Capacity Planning and Scheduling is the process of creating a production plan that includes all of the operations that are required to fulfill customer demand. During this process, operations are scheduled on resources that can represent machines, labor, tools, storage, or other equipment.

Traditional planning systems ignore the actual capacity available on these machines. This means that, as orders come in, the operations are scheduled without knowing whether the resources have enough capacity to perform the work and if materials are available.

It is crucial that facilities have processes in place to manufacture products in a timely manner based on changing customer demand. Without accounting for capacity and material constraints, the production schedule is at risk of being inaccurate and not feasible.

This can result in promising customer orders that cannot be completed on time based on the available resource and materials. Missing shipment dates will result in unhappy customers, the loss of future business, and unhappy shop floor employees as orders will need to be rushed.

With finite capacity scheduling, operations are only scheduled when resources and materials are available. This technique can help you optimize your inventory flow, shorten the delivery time, and accurately plan production to meet changing demand.

Finite Capacity Planning Made Easy

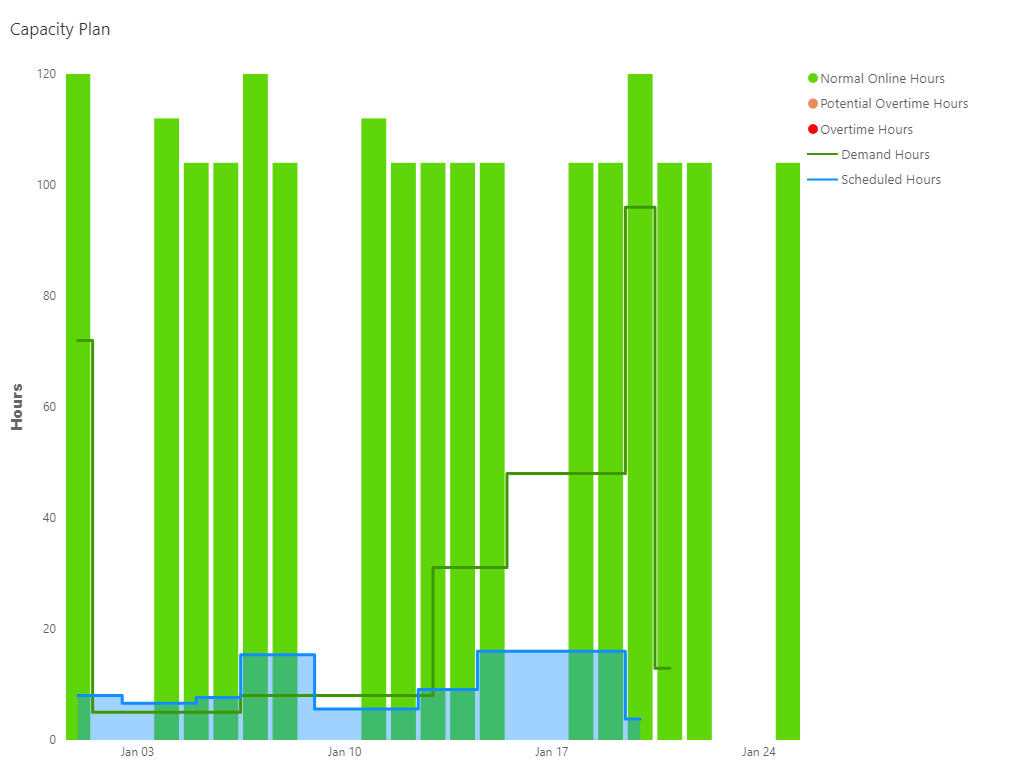

Capacity planning is an important aspect of production planning as it tells you if your production plan is realistic and feasible. If the planned production is greater than the available capacity, your production plan will not be completed and you will likely have late orders.

While the right capacity planning and optimization rules are important, there are techniques that can help maximize the available capacity you already possess.

Calculating resource capacity requirements for hundreds or thousands of jobs can be extremely time-consuming. That is why many planners choose to use technology to gather data from various sources to quickly calculate how much capacity is required to complete all jobs in time.

An Advanced Planning and Scheduling software can help assess the amount of work that can be done within a given time frame. These tools take resource constraints into consideration to ensure that work proceeds at a balanced and efficient pace throughout the production process.

PlanetTogether’s Advanced Planning and Scheduling system knows which resources can perform which type of work, when these resources are available, when the material is available, and the run rates of the resources. The system can then take all of this information into consideration and automatically generate a production schedule that is actually feasible based on the amount of capacity available on your resources.

A finite capacity scheduling software allows for strategic, tactical, and operational planning capabilities which represent the basis for substantial competitive advantage and customer satisfaction.

PlanetTogether enables us to provide a quality product to our customers in a timely manner.

GREGORY VAN LEIRSBURG, PRODUCTION SCHEDULER, STANDARD PROCESS SUPPLEMENTS

Concurrent Planning and Scheduling with PlanetTogether

Manufacturers must create accurate production plans so that they can give accurate promise dates to their customers.

Too often, manufacturing companies have production plans that get disconnected from the materials and capacity scheduling of the work centers. Tasks are scheduled at the work center level in time buckets. The problem here is that the schedule does not take into consideration different run rates of resources. In addition, the sequence of tasks is not clear - schedulers do not know exactly when a task will start.

These problems severely limit your ability to give customers accurate promise dates and to understand the impact of change on promise dates.

Concurrent Planning & Scheduling allows you to:

- Commit quickly

- Promise delivery dates realistically

- React to disruptions efficiently

- Deliver on-time reliably

An Advanced Planning and Scheduling System quickly and automatically creates a concurrent production plan and schedule that takes into consideration all of the constraints, sequencing preferences, and management priorities you have.

Being able to plan and schedule together will allow for better coordination across departments. This can help reduce waste as all departments will have visibility in the number of items that are available and are being produced.

PlanetTogether’s Advanced Planning and Scheduling system allows you to have extended visibility between your scheduling, production, and procurement departments to keep demand and supply aligned to improve customer service and meet your delivery dates. It will also allow you to reduce your material costs while minimizing schedule disruptions.

PlanetTogether Advanced Planning and Scheduling (APS) Software

Advanced Planning and Scheduling software has become a must for modern-day manufacturing operations as customer demand for increased product assortment, fast delivery, and downward cost pressures become prevalent. These systems help planners save time while providing greater agility in updating ever-changing priorities, production schedules, and inventory plans. APS Systems can be quickly integrated with an ERP/MRP software to fill the gaps where these systems lack planning and scheduling flexibility, accuracy, and efficiency.

With PlanetTogether APS you can:

- Create optimized schedules that balance production efficiency and delivery performance

- Maximize throughput on bottleneck resources to increase revenue

- Synchronize supply with demand to reduce inventories

- Provide company-wide visibility to resource capacity

- Enable scenario data-driven decision making

The implementation of an Advanced Planning and Scheduling (APS) Software will take your manufacturing operations to the next level of production efficiency by taking advantage of the operational data you already possess in your ERP system. APS is a step in the right direction of efficiency and lean manufacturing production enhancement.

Try out a free demo to learn more today!

Related Capacity Planning Video

APS Resources