Production Planning and Control (PPC) is a term used to describe two strategies: production planning and production control. PPC is an essential component of operations management as it enables production facilities to optimize the utilization of resources required for production.

Production Planning Tools

In production planning and control, the production plan becomes the guidepost for all operations. It is the tool that will make the manufacturing organization run as smoothly as possible. This is why generating a production plan and schedule that everyone can easily comprehend, interpret, and be fully aware of is essential.

Planning is a vital, yet often challenging, first step in the very complex process of tackling a production order, but it forms the basis of measuring and meeting production goals and forecasts.

One important tool that is commonly used to represent the production schedule is a Gantt chart. The move from paper schedules to spreadsheets and then to real-time, integrated Gantt screens in advanced planning and scheduling (APS) systems have revolutionized manufacturing and production planning.

Gantt charts are commonly used in project management, production timelines, and resource management where multiple interdependent tasks must be sequenced on one timeline.

What is a Gantt Chart?

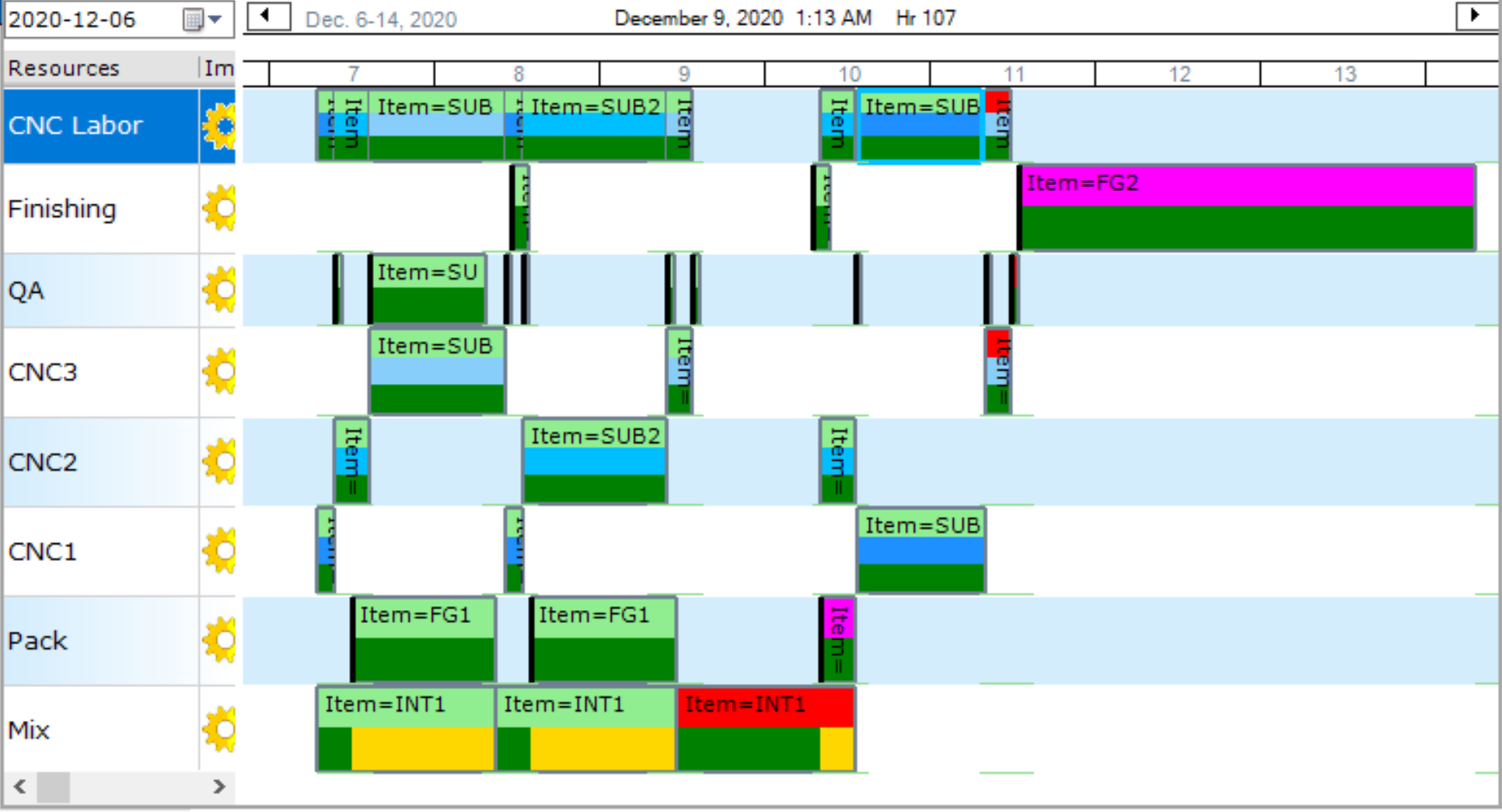

A Gantt chart is a visual representation of all tasks or operations scheduled on specific resources. In this type of chart, activity blocks (representing operations) are arranged on horizontal lines (representing resources). All of the blocks are arranged on the same timeline, which allows everyone to know when the operations will start and finish.

In addition, the length of the activity block is proportional to the time required to perform the operation. This way, you can easily see which tasks take longer than others and may decide to split those operations between resources to met your need dates.

Gantt Charts Provide Visibility

Common benefits of task interdependence visibility aid in the the reliability of:

- On-time Delivery

- Scheduling Precision

- Production Plan Adherence

- Overall Process Control

- Cost to Produce is Lowered

- Cost Effective/Material Planning

Effectively coordinating all of your resources and manage a single production schedule will allow your operations to run closer to what is planned and ultimately allow you to meet your promise dates.

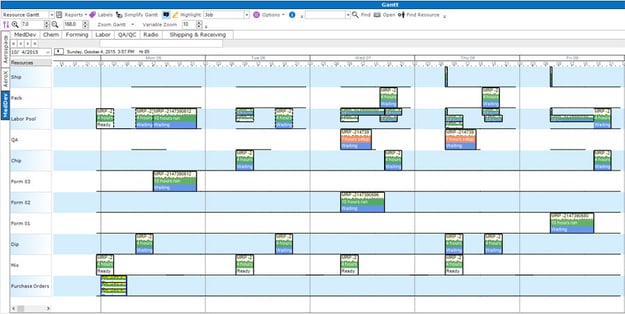

Gantt Charts in PlanetTogether APS

Advanced Planning and Scheduling (APS) softwares that have Gantt screens are highly advantageous for manufacturing companies. These softwares utilize Gantt screens to increase the visibility of the operations that are consuming resource capacity. An APS system like PlanetTogether that can be integrated directly to your ERP or MRP system allows you to pull in all of the right information and automatically create an optimized production schedule.

PlanetTogether APS separates itself in the APS industry with its Gantt scheduling interface. Instead of having to move each task individually, moving one job will automatically move the other related tasks as well. The advantages of PlanetTogether APS eliminate the need to worry about mistakes in leaving gaps between tasks (lost time) that can occur with some APS systems. This unique ability allows for a quicker and easier scheduling process.

PlanetTogether's drag-and-drop functionality provides an additional level of dynamic planning that automatically allows you to see the impact of any changes in real-time. The status of the job (on-time, late, constrained) will be displayed by the use of activity block colors, which allows the planners and schedulers to identify problem areas before they occur. Bottleneck response, line rerouting, and material substitution are possible in real-time. What-If scenarios can be used to experiment with in-house theories of increased output by changing the optimization settings without affecting your live schedule.

Overall, Gantt charts are an extremely useful tool in production facilities that complete multi-resource production tasks as they allow everyone to be on the same page as to what is to be produced. Their universal 'output' explains why they are used by most industry sectors to orchestrate the interaction of labor, equipment, and materials.

Advanced Planning and Scheduling (APS) Software

Advanced Planning and Scheduling (APS) software has become a must for modern-day manufacturing operations as customer demand for increased product assortment, fast delivery, and downward cost pressures become prevalent. These systems help planners same time while providing greater agility in updating ever-changing priorities, production schedules, and inventory plans. APS Systems can be quickly integrated with an ERP/MRP software to fill the gaps where these systems lack planning and scheduling flexibility, accuracy, and efficiency.

With PlanetTogether APS you can:

- Create optimized schedules that balance production efficiency and delivery performance

- Maximize throughput on bottleneck resources to increase revenue

- Synchronize supply with demand to reduce inventories

- Provide company-wide visibility to resource capacity

- Enable scenario data-driven decision-making

The implementation of an Advanced Planning and Scheduling (APS) Software will take your manufacturing operations to the next level of production efficiency by taking advantage of the operational data you already possess in your ERP system. APS is a step in the right direction of efficiency and lean manufacturing production enhancement. Try out a free trial or demo!

Video: Drag and Drop Gantt Screen

APS Resources