What You Need to Know About Production Planning & Control

Throughout the years, manufacturers have been on a quest to improve their operations by increasing productivity, managing their inventory, and optimizing their resource utilization. These are some of the main challenges faced by manufacturers. Many strategies have emerged as solutions to allow manufacturing operations to improve their overall production efficiency.

One such strategy is Production Planning and Control (PPC), which is a term used to describe two essential components of manufacturing: production planning and production control. The production planning portion handles the activities necessary before production actually begins, such as materials planning, capacity planning, and operations scheduling. The production control portion oversees the actual production process by ensuring that the production team is able to meet its production targets and is operating according to schedule.

Overall, production planning and control can play a substantial role in production through schedule optimization, waste reduction, and cost minimization.

Why Production Planning & Control Matters More Than Ever

For many manufacturers, the techniques and strategies used in production planning and control have been extremely beneficial in improving their operations. Some of the most beneficial features of production planning and control include the following:

-

Customer Service Enhancement

- The production planning component of PPC ensures that the organization can deliver a finished product on time. Customers can benefit from having high-quality products being delivered promptly due to improved scheduling and optimized production. These improvements ultimately win customers over and can persuade them to establish a profitable and ongoing relationship with the manufacturing organization.

-

Inventory Control

- Proper inventory management can be a challenging thing to achieve as planners must balance holding enough inventory to satisfy customer demand while minimizing the risks and costs of holding too much inventory. With a promising production planning and control system, inventory planning becomes much easier. These types of systems allow planners to only purchase enough materials to fulfill orders which reduces the need for holding a lot of raw materials. In addition, they can provide the tools for utilizing a Just-In-Time scheduling strategy, which further reduces the need for holding finished goods or large quantities of work-in-process items.

-

Equipment Improvement

- Production planning and control will ultimately unveil areas and machines that are not able to meet their production targets. These could signal a lack of productivity due to faulty equipment which can be remedied by scheduling regular maintenance and cleaning for the underperforming resources. This will enable you to have equipment that is able to meet the targeted production outputs and ensure that the resources are being used efficiently. In addition, the capacity planning aspect of production planning and scheduling will ensure that all resources are being utilized to their full potential.

-

Plant Morale Improvement

- Stress can be a tremendous hindrance in manufacturing as it increases the likelihood of errors and defects on the shop floor. A production planning and control system that ensures a systematic workflow through the production flow allows planners to better quote lead times. The overall outcome is that activities are properly coordinated and there is no need to rush orders to meet deadlines. The shop floor personnel are then able to know what needs to be done and are able to meet their production goals without the stress of rushing orders due to a disorganized plan.

-

Idle Time Reduction

- In manufacturing production, idle time refers to the paid time where an employee or machine is unproductive. Idle time is usually due to workers waiting for materials to begin production or on various machine repairs. These periods of low productivity can be costly for manufacturers. However, production planning and control is a viable solution to minimize downtime as it can effectively coordinate the purchasing and release of materials to ensure that every production step can start when scheduled.

-

Quality Improvement

- High-quality products must be able to meet industry standards at various checkpoints in the manufacturing process. As production planning and control overlook all aspects of production from materials planning to resource optimization, this ensures that the quality of the finished goods is maintained. Having quality products is critical nowadays to ensure the satisfaction of customers. Your customers will be more likely to choose and endorse your brand if they know that your products are consistently reliable and durable.

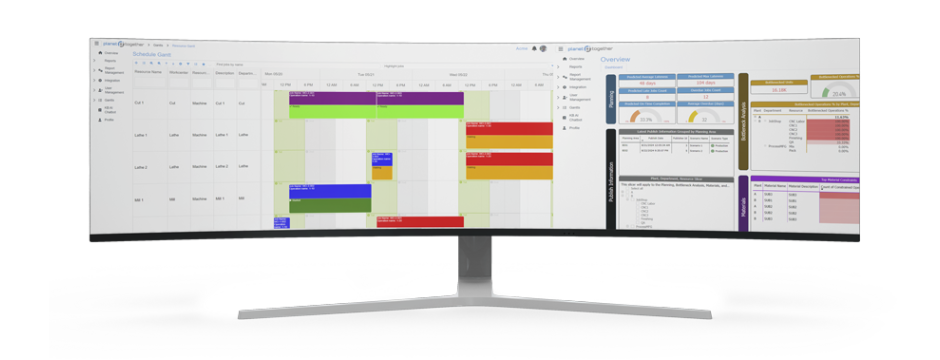

The many benefits of production planning and control show that it can increase a business's revenues by maximizing the utilization of its resources. Overall, if the individual components within the organization are not working well together, there will only be a limited amount of success for the entire manufacturing operation. A software that is becoming extremely common to handle production planning and control strategies is PlanetTogether's advanced planning and scheduling (APS) software. This type of software provides insight into the current operations and allows the planning and scheduling to occur concurrently to increase the efficiency of the operations.

PlanetTogether has cut the number of 'hot' jobs in our schedule so that we can schedule our resources more efficiently. This is translated into a better work environment for everyone.

PRODUCTION SCHEDULER, FOOD PRODUCTION INDUSTRY

Level Up Production Planning with Advanced Scheduling Tools

Advanced Planning and Scheduling Softwares have become a must for modern-day manufacturing operations as customer demand for increased product assortment, fast delivery, and downward cost pressures become prevalent. These systems help planners save time while providing greater agility in updating ever-changing priorities, production schedules, and inventory plans. APS Systems can be quickly integrated with an ERP/MRP software to fill the gaps where these systems lack planning and scheduling flexibility, accuracy, and efficiency.

With PlanetTogether APS you can:

- Create optimized schedules that balance production efficiency and delivery performance

- Maximize throughput on bottleneck resources to increase revenue

- Synchronize supply with demand to reduce inventories

- Provide company-wide visibility to resource capacity

- Enable scenario data-driven decision making

The implementation of an Advanced Planning and Scheduling (APS) Software will take your manufacturing operations to the next level of production efficiency by taking advantage of the operational data you already possess in your ERP system. APS is a step in the right direction of efficiency and lean manufacturing production enhancement. Try out a free trial or demo!

APS Resources