Leveraging Advanced Analytics for Demand Forecasting and Inventory Management

Plant managers face the continuous challenge of meeting fluctuating demand while optimizing inventory levels. In this digital age, where data reigns supreme, advanced analytics emerges as a game-changer in the pursuit of streamlined operations and enhanced decision-making.

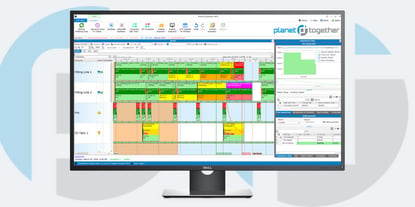

This blog is dedicated to exploring the transformative potential of advanced analytics for demand forecasting and inventory management in medical manufacturing facilities. Specifically, we'll look into the integration between PlanetTogether, a leading advanced planning and scheduling software, and prominent ERP, SCM, and MES systems such as SAP, Oracle, Microsoft, Kinaxis, Aveva, and others. Let's embark on a journey to unlock the power of data-driven insights in optimizing your manufacturing processes.

Understanding the Challenges

Before looking into solutions, it's crucial to grasp the challenges that plant managers encounter in demand forecasting and inventory management:

Fluctuating Demand: Medical manufacturing is characterized by volatile demand patterns influenced by factors like seasonal variations, market trends, and unpredictable events such as pandemics.

Complex Supply Chains: The intricate network of suppliers, distributors, and stakeholders adds layers of complexity to supply chain management, making it challenging to synchronize operations effectively.

Inventory Optimization: Maintaining optimal inventory levels is a delicate balancing act. Excess inventory ties up capital and space, while insufficient stock leads to stockouts and customer dissatisfaction.

Data Overload: With vast amounts of data generated across various touchpoints, extracting actionable insights becomes overwhelming without robust analytics tools.

Addressing these challenges requires a proactive approach empowered by advanced analytics capabilities.

The Role of Advanced Analytics

Advanced analytics encompasses a spectrum of techniques including machine learning, predictive modeling, and data mining, among others. By harnessing the power of data, advanced analytics empowers plant managers to make informed decisions, anticipate market trends, and optimize operations with precision.

Let's explore how advanced analytics can revolutionize demand forecasting and inventory management:

Predictive Demand Forecasting: Traditional forecasting methods often fall short in capturing the intricacies of medical manufacturing demand. Advanced analytics leverages historical data, market trends, and external factors to generate accurate demand forecasts. Machine learning algorithms adapt to evolving patterns, enabling proactive decision-making and minimizing the impact of demand fluctuations.

Dynamic Inventory Optimization: Static inventory management approaches are ill-equipped to navigate the complexities of medical manufacturing. Advanced analytics enables dynamic inventory optimization by analyzing demand patterns, supplier performance, lead times, and production capacities in real-time. By balancing inventory levels with demand variability, plant managers can mitigate risks, reduce costs, and enhance customer satisfaction.

Integration with PlanetTogether and ERP, SCM, MES Systems

The seamless integration between advanced planning and scheduling (APS) software like PlanetTogether and enterprise systems such as SAP, Oracle, Microsoft Dynamics, Kinaxis RapidResponse, Aveva, and other ERP, SCM, and MES platforms is instrumental in unlocking the full potential of advanced analytics. Here's how:

Data Synchronization: Integration ensures a synchronized flow of data between different systems, eliminating silos and enabling a holistic view of operations. Real-time data exchange facilitates accurate demand forecasting and inventory optimization, driving agility and responsiveness in manufacturing processes.

Unified Planning Environment: By integrating APS with ERP, SCM, and MES systems, plant managers gain access to a unified planning environment. This cohesive ecosystem enables end-to-end visibility, collaborative decision-making, and seamless execution of production plans. Whether it's scheduling production runs, allocating resources, or managing inventory levels, integration empowers plant managers with comprehensive control over their operations.

Enhanced Decision Support: Advanced analytics thrives on data integration. By consolidating data from disparate sources, plant managers can leverage advanced analytics tools embedded within APS software to gain actionable insights. From identifying demand trends to optimizing inventory policies, integrated systems provide decision-makers with the analytical firepower needed to stay ahead in a competitive market landscape.

Scalability and Flexibility: In a rapidly evolving industry like medical manufacturing, scalability and flexibility are essential. Integration between PlanetTogether and ERP, SCM, and MES systems offers scalability to accommodate changing business needs and flexibility to adapt to evolving market dynamics. Whether expanding operations, launching new product lines, or entering new markets, integrated systems provide the foundation for sustainable growth and innovation.

Best Practices for Implementation

While the benefits of integrating PlanetTogether with ERP, SCM, and MES systems are undeniable, successful implementation requires careful planning and execution. Here are some best practices to maximize the effectiveness of integration:

Define Clear Objectives: Clearly define the objectives and expected outcomes of integration, whether it's improving demand forecasting accuracy, reducing inventory holding costs, or enhancing production efficiency.

Engage Stakeholders: Collaboration is key to successful integration. Involve key stakeholders from IT, operations, finance, and supply chain management to ensure alignment of goals and priorities.

Data Quality Assurance: Establish data governance processes to ensure data accuracy, consistency, and integrity across integrated systems. Invest in data cleansing, normalization, and validation to enhance the reliability of analytics insights.

Continuous Improvement: Integration is not a one-time event but an ongoing journey. Foster a culture of continuous improvement, where feedback loops and performance metrics drive iterative refinements to the integrated ecosystem.

In the competitive landscape of medical manufacturing, plant managers must embrace advanced analytics as a strategic imperative for sustainable growth and operational excellence. By leveraging the integration between PlanetTogether and leading ERP, SCM, and MES systems, plant managers can harness the power of data-driven insights to optimize demand forecasting and inventory management processes.

From predictive analytics to dynamic inventory optimization, advanced analytics empowers plant managers with the tools needed to navigate uncertainty, mitigate risks, and capitalize on emerging opportunities.

By embracing integration and adopting best practices, plant managers can position their facilities at the forefront of innovation, resilience, and efficiency in the ever-evolving realm of medical manufacturing. Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.