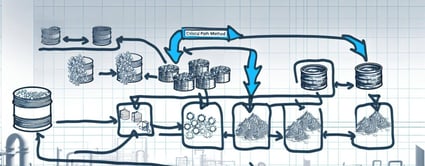

Leveraging Critical Path Method (CPM)

As a Purchasing Manager, you're acutely aware of the intricate dance involved in managing resources, timelines, and costs to ensure smooth operations. One indispensable tool in your arsenal for achieving these goals is the Critical Path Method (CPM) in project scheduling.

In this blog, we'll look into the significance of CPM and explore how integrating it with sophisticated software solutions like PlanetTogether can revolutionize project management within your facility, particularly when combined with ERP, SCM, and MES systems such as SAP, Oracle, Microsoft, Kinaxis, and Aveva.

Critical Path Method (CPM)

At its core, CPM is a project management technique used to determine the longest sequence of dependent tasks and identify the most critical activities that directly impact project completion. By pinpointing these critical tasks, project managers can allocate resources efficiently, minimize delays, and optimize timelines.

For chemical manufacturing facilities, where production processes are often complex and interdependent, CPM offers invaluable insights into project scheduling. Whether it's a plant expansion, a new product launch, or a maintenance shutdown, CPM enables meticulous planning and execution, ultimately driving productivity and profitability.

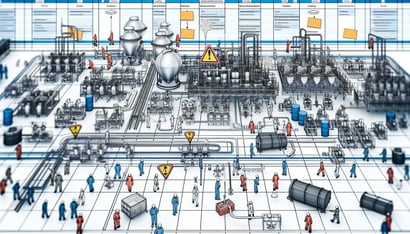

Challenges in Project Scheduling for Chemical Manufacturing

In the dynamic environment of chemical manufacturing, several challenges complicate project scheduling:

- Resource Allocation: Balancing manpower, equipment, and materials across multiple projects while avoiding bottlenecks requires careful coordination.

- Process Complexity: Chemical manufacturing processes involve intricate sequences of reactions, handling various substances, each with its own set of requirements and constraints.

- Regulatory Compliance: Strict adherence to safety and environmental regulations adds another layer of complexity to project scheduling, necessitating meticulous planning and documentation.

- Market Dynamics: Fluctuating market demands and unforeseen disruptions can impact project timelines, making agility and adaptability essential.

Addressing these challenges demands a holistic approach to project management, one that integrates advanced scheduling techniques like CPM with robust software solutions.

The Power of Integration: PlanetTogether and ERP, SCM, and MES Systems

PlanetTogether stands out as a leading solution for advanced production planning and scheduling. By integrating PlanetTogether with ERP, SCM, and MES systems such as SAP, Oracle, Microsoft, Kinaxis, and Aveva, chemical manufacturing facilities can unlock a myriad of benefits:

- Seamless Data Exchange: Integration facilitates real-time data synchronization between scheduling and enterprise systems, ensuring accuracy and consistency across the board.

- Enhanced Visibility: Purchasing managers gain comprehensive visibility into resource availability, project statuses, and critical path analysis, empowering informed decision-making.

- Predictive Analytics: Leveraging historical data and predictive algorithms, integrated systems can anticipate potential bottlenecks, enabling proactive mitigation strategies.

- Streamlined Workflows: Automation of routine tasks and workflows minimizes manual intervention, reducing errors and improving operational efficiency.

- Scalability and Flexibility: Integrated solutions can adapt to evolving business needs, accommodating changes in production volumes, market demands, and regulatory requirements seamlessly.

In chemical manufacturing, effective project scheduling is a linchpin of success. By harnessing the power of the Critical Path Method (CPM) and integrating advanced scheduling solutions like PlanetTogether with ERP, SCM, and MES systems, purchasing managers can elevate their facility's efficiency, agility, and profitability.

As you navigate the complexities of project management, remember that integration is key. By breaking down silos between planning, execution, and monitoring functions, integrated solutions empower you to make data-driven decisions, optimize resource utilization, and stay ahead of the curve in today's dynamic marketplace.

Embrace the transformative potential of CPM integration and unlock new possibilities for your chemical manufacturing facility. The path to operational excellence starts with strategic planning, meticulous execution, and a commitment to continuous improvement.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.