Leveraging Predictive Analytics for Enhanced Manufacturing Efficiency

Production planners play a pivotal role in optimizing manufacturing processes and resource allocation to ensure efficiency and profitability. In packaging manufacturing, staying ahead requires more than just reacting to market trends or production challenges as they arise. With the advent of predictive analytics, production planners now have powerful tools at their disposal to forecast demand, anticipate bottlenecks, and optimize resource utilization.

In this blog, we'll explore the development of predictive analytics models and their integration with enterprise resource planning (ERP), supply chain management (SCM), and manufacturing execution systems (MES), focusing on the integration between PlanetTogether and various ERP systems like SAP, Oracle, Microsoft, Kinaxis, and Aveva.

Predictive Analytics in Manufacturing

Predictive analytics involves the use of statistical algorithms and machine learning techniques to analyze historical data and make predictions about future events or trends. In the context of manufacturing, predictive analytics can be used to forecast demand, identify potential production issues, optimize inventory levels, and improve overall operational efficiency.

For production planners, predictive analytics offers invaluable insights into various aspects of the manufacturing process:

Demand Forecasting: By analyzing historical sales data, market trends, and other relevant factors, predictive analytics can help production planners accurately forecast demand for packaging products. This enables better resource planning and prevents overproduction or stockouts.

Production Optimization: Predictive analytics models can identify potential bottlenecks in the production process and recommend optimization strategies to improve throughput and minimize downtime. This could involve adjusting production schedules, reallocating resources, or implementing preventive maintenance measures.

Inventory Management: By predicting future demand and lead times, production planners can optimize inventory levels to ensure adequate stock availability while minimizing carrying costs and obsolescence risks.

Resource Allocation: Predictive analytics can help production planners allocate resources such as raw materials, equipment, and manpower more efficiently, taking into account factors like production schedules, resource availability, and production constraints.

Integration with ERP, SCM, and MES Systems

To fully leverage the power of predictive analytics in manufacturing, it's essential to integrate these analytics capabilities with existing ERP, SCM, and MES systems. Integration allows for seamless data exchange between different systems, enabling production planners to access real-time data and insights for informed decision-making.

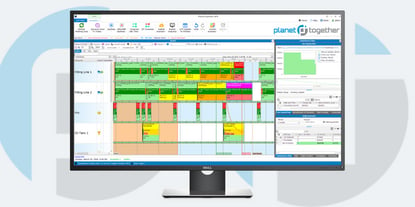

PlanetTogether is a leading production planning and scheduling software that offers robust predictive analytics capabilities. Its integration with ERP systems such as SAP, Oracle, Microsoft Dynamics, Kinaxis RapidResponse, Aveva, and others enhances its functionality and usability for production planners.

Here's how integration with ERP, SCM, and MES systems enhances predictive analytics in manufacturing:

Data Synchronization: Integration ensures that relevant data, such as sales orders, inventory levels, production schedules, and resource availability, is synchronized between PlanetTogether and ERP, SCM, and MES systems in real-time. This provides production planners with accurate and up-to-date information for forecasting and decision-making.

Seamless Workflow: Integrated systems enable a seamless workflow from demand forecasting to production planning and execution. Production planners can easily access predictive analytics insights within their familiar ERP or MES interface, streamlining the decision-making process.

Enhanced Visibility: Integration provides production planners with enhanced visibility into the entire manufacturing process, from raw material procurement to finished goods delivery. This visibility allows for proactive management of production issues and better alignment with business objectives.

Automated Processes: Integrated systems enable automation of routine tasks such as data entry, scheduling, and reporting, freeing up time for production planners to focus on strategic activities. This automation improves efficiency and reduces the risk of human error.

In the competitive manufacturing environment, production planners need to leverage advanced analytics tools to optimize manufacturing processes and resource allocation. Predictive analytics offers valuable insights into demand forecasting, production optimization, inventory management, and resource allocation, enabling production planners to make informed decisions and drive operational efficiency.

By integrating predictive analytics capabilities with ERP, SCM, and MES systems such as PlanetTogether with SAP ERP, production planners can access real-time data and insights, streamline workflows, and automate routine tasks, ultimately enhancing manufacturing efficiency and competitiveness.

As the manufacturing landscape continues to evolve, production planners who embrace predictive analytics and leverage integrated systems will be well-positioned to succeed in the ever-changing market dynamics of the packaging industry.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.