Technological Advancements: Agile Workforce Training

In the ever-evolving landscape of manufacturing, particularly in the packaging industry, technological advancements are driving rapid transformations. From automated processes to smart factories, the industry is witnessing a paradigm shift. Amidst this change, one of the critical aspects that require immediate attention is the upskilling and training of the workforce. As manufacturing IT professionals in a packaging manufacturing facility, you're at the forefront of this revolution, tasked with integrating cutting-edge technologies while ensuring that your workforce remains adept and agile in their roles.

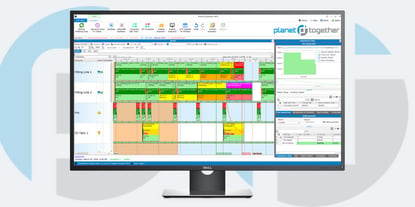

In this blog, we'll look into the significance of agile workforce training programs and explore how they can be effectively implemented to adapt to technological advancements. Additionally, we'll discuss the integration between PlanetTogether, a leading production planning and scheduling software, and various ERP, SCM, and MES systems like SAP, Oracle, Microsoft, Kinaxis, and Aveva, showcasing the synergy between technology and workforce capabilities.

The Need for Agile Workforce Training

As automation, AI, and other advanced technologies permeate the manufacturing sector, the demand for highly skilled workers is on the rise. However, the skills required today are vastly different from those needed in the past. Traditional manufacturing roles are giving way to positions that require proficiency in data analysis, programming, and troubleshooting of complex systems.

Agile workforce training programs play a pivotal role in bridging this skills gap. These programs are designed to be flexible, dynamic, and responsive to changing technological landscapes. They empower employees to adapt quickly to new tools and processes, fostering a culture of continuous learning and innovation within the organization.

Benefits of Agile Workforce Training Programs

Enhanced Productivity: A well-trained workforce is more efficient and productive. By equipping employees with the latest skills and knowledge, organizations can optimize their manufacturing processes and minimize downtime.

Improved Quality: With proper training, employees can better understand and utilize advanced machinery and software, leading to higher quality products and reduced defects.

Increased Flexibility: Agile training programs enable employees to adapt to changes in technology or production requirements more effectively, allowing the organization to respond swiftly to market demands.

Employee Satisfaction and Retention: Investing in employee development demonstrates a commitment to their growth and success, leading to higher job satisfaction and increased employee retention rates.

Integrating PlanetTogether with ERP, SCM, and MES Systems

Now, let's explore how the integration of PlanetTogether with ERP, SCM, and MES systems can facilitate agile workforce training and upskilling:

Seamless Data Exchange: Integration enables real-time data exchange between production planning and scheduling systems (such as PlanetTogether) and other enterprise systems like SAP, Oracle, Microsoft, Kinaxis, and Aveva. This ensures that employees have access to accurate and up-to-date information, enabling them to make informed decisions.

Streamlined Processes: By connecting production planning with other critical systems, integration eliminates manual data entry and reduces the risk of errors. This streamlines manufacturing processes and enhances overall efficiency.

Enhanced Visibility: Integrated systems provide greater visibility into production workflows, resource allocation, and inventory levels. This visibility enables employees to identify bottlenecks, anticipate potential issues, and make data-driven decisions to optimize operations.

Support for Training Initiatives: Integration can also support training initiatives by providing access to relevant data and insights within familiar interfaces. For example, employees can receive training on how to interpret production schedules generated by PlanetTogether directly within their ERP or MES system.

Agile workforce training programs are essential for packaging manufacturing facilities to adapt to technological advancements and remain competitive in today's market. By investing in employee development and integrating advanced software solutions like PlanetTogether with ERP, SCM, and MES systems, organizations can unlock new levels of efficiency, productivity, and innovation.

As manufacturing IT professionals, it's crucial to recognize the symbiotic relationship between technology and workforce capabilities and to champion initiatives that empower employees to thrive in the digital age. By embracing agile workforce training, you can position your organization for long-term success in an ever-evolving industry landscape.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.