Planning for Geopolitical Risks in Global Manufacturing: How APS Integration Shields the Supply Chain

In industrial manufacturing, supply chain managers face an increasingly complex challenge: geopolitical risk. From trade wars and sanctions to regional conflicts, labor strikes, and shifting regulatory environments, global manufacturing networks are under constant pressure. These forces can disrupt the flow of raw materials, upend production schedules, and create sudden spikes in costs, threatening both profitability and reliability.

For supply chain managers in industrial manufacturing, proactive planning isn’t just smart—it’s survival. Fortunately, today’s advanced planning and scheduling (APS) systems, especially when integrated with leading ERP platforms like SAP, Oracle, Microsoft, Kinaxis, or Aveva, offer the digital tools needed to assess, mitigate, and respond to geopolitical disruptions with speed and precision.

This blog explores how integrating a robust APS like PlanetTogether into your ERP ecosystem can help shield your global manufacturing operations against geopolitical risks, transforming uncertainty into strategic advantage.

Understanding Geopolitical Risks in Industrial Supply Chains

Industrial manufacturers rely on vast global supply networks. Raw materials may come from multiple continents; subcomponents are often produced through international partnerships; final assembly and distribution channels stretch across borders. This intricate web makes supply chains vulnerable to external shocks.

Some key geopolitical risks that supply chain managers must navigate include:

Trade wars and tariffs — Government-imposed duties and quotas can make critical materials suddenly costlier or inaccessible.

Regional conflicts and sanctions — Political instability or international sanctions can block entire supplier networks overnight.

Shifting environmental and labor regulations — Changing compliance landscapes can delay operations or impose unexpected costs.

Pandemics and border restrictions — As seen with COVID-19, global crises can freeze cross-border flows, impacting material availability and labor.

Cybersecurity and intellectual property (IP) threats — Tensions between nations can elevate the risk of cyberattacks or theft, especially in industries relying on proprietary technologies.

To survive—and thrive—in this environment, supply chain leaders must evolve from reactive to proactive. They need systems that provide real-time visibility, predictive scenario modeling, and dynamic scheduling, allowing them to pivot before risk materializes into crisis.

The Role of APS in Geopolitical Risk Management

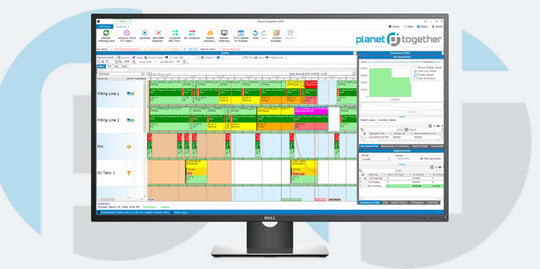

Traditional ERP systems offer transactional backbone and resource management, but they often fall short when it comes to rapid planning adjustments, “what-if” scenario modeling, or multi-plant optimization. This is where an APS like PlanetTogether steps in.

By integrating PlanetTogether APS with ERP giants like SAP, Oracle, Microsoft, Kinaxis, or Aveva, manufacturers unlock critical capabilities:

Advanced visibility into constraints and dependencies

APS systems map how materials, production lines, labor, and logistics interconnect. If geopolitical tensions threaten one supplier or region, planners can instantly see which parts of the schedule will be affected—and which alternatives exist.

Scenario modeling for contingency planning

PlanetTogether’s APS enables “what-if” simulations, letting managers model various geopolitical scenarios (e.g., a trade embargo or port closure) to understand potential downstream impacts on production capacity and delivery timelines.

Dynamic rescheduling and optimization

Once risks are identified, APS tools can rapidly adjust production schedules across multi-plant networks, shifting orders or rebalancing capacity to reduce exposure. Integration with ERP systems ensures that material availability, financials, and customer commitments remain aligned.

Enhanced supplier collaboration and agility

APS-integrated systems improve communication with suppliers by sharing forecasts, demand shifts, and capacity changes early, reducing lead times and allowing upstream partners to adjust.

Inventory optimization under uncertainty

Through predictive analytics, APS can help balance just-in-time strategies with the need for strategic stockpiling in volatile environments, optimizing working capital while maintaining service levels.

Integration Benefits: Why APS + ERP Is Stronger Together

While APS systems are powerful on their own, their true value emerges when they’re seamlessly integrated with ERP platforms like SAP, Oracle, Microsoft, Kinaxis, or Aveva. This synergy offers several key benefits:

Unified data foundation

APS relies on accurate, up-to-date data from across the organization—procurement, inventory, production, sales. Integration ensures a single source of truth, avoiding mismatches and manual data handling.

Faster, automated decision-making

An integrated system can automatically trigger rescheduling, material reallocation, or supplier adjustments when certain risk thresholds are crossed, reducing the time from risk identification to action.

Enterprise-wide visibility

Geopolitical risks rarely affect just one department. Integration ensures that supply chain managers, plant operators, finance leaders, and executives all see the same risk landscape and can coordinate responses.

Scalability across regions

For manufacturers operating across multiple countries, an integrated APS-ERP environment ensures consistency in planning and risk management, even when local markets behave differently.

In an era where geopolitical risks are the new normal, industrial manufacturers that master agile, data-driven supply chain management will outperform those that rely on outdated, reactive practices.

Integrating PlanetTogether APS with your ERP backbone doesn’t just help mitigate disruptions—it transforms geopolitical complexity into a competitive differentiator. By gaining the ability to see, simulate, and adjust to risks faster and smarter, supply chain managers can position their companies to capture market share when others falter.

As global dynamics continue to evolve, the question isn’t whether to prepare, but how. And the answer increasingly points to integrated, advanced planning systems that bring clarity, speed, and resilience to the heart of industrial supply chains.

Supply chain managers, it’s time to move beyond spreadsheets and static plans. Equip your global manufacturing operation with the right digital tools to face geopolitical uncertainty head-on. PlanetTogether APS, integrated with SAP, Oracle, Microsoft, Kinaxis, or Aveva, can help you turn today’s risks into tomorrow’s opportunities.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.