Precision Forecasting: How Industrial Manufacturers Can Align Production with Market Expectations

In industrial manufacturing, forecasting is no longer just a useful tool—it’s a critical business function. For Production Planners in industrial manufacturing, the ability to predict market demand accurately means the difference between agility and stagnation. Disruptions in global supply chains, evolving customer expectations, and shortened product life cycles all amplify the need for reliable, real-time forecasting.

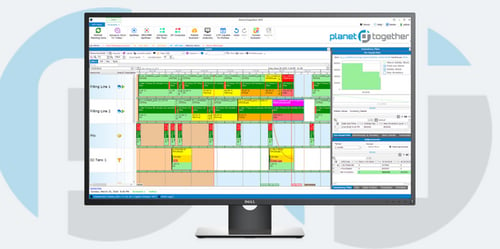

At the heart of this transformation lies Advanced Planning and Scheduling (APS) software like PlanetTogether, especially when integrated with robust enterprise systems such as SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva.

This blog explores how the synergy between forecasting and APS can empower production planners to exceed market expectations and meet organizational goals.

The Production Planner’s Dilemma: Juggling Demand, Resources, and Deadlines

Production Planners are often caught in a balancing act:

Aligning production capacity with fluctuating customer demand

Ensuring efficient resource utilization without overproduction or stockouts

Managing lead times and supplier constraints

Staying compliant with quality and regulatory standards

Forecasting is a powerful lever to manage these complexities, but only when it's backed by real-time data and connected systems. Traditional tools like spreadsheets or legacy ERP modules struggle to keep pace with today’s needs.

Why Market Forecasting Matters More Than Ever

Here’s why forecasting market expectations is a top priority:

Customer-Centric Production: Today’s industrial buyers expect tailored solutions, faster delivery, and high quality. Anticipating their needs allows planners to pre-position inventory and resources.

Volatile Demand Cycles: Economic shifts, geopolitical tensions, and raw material shortages impact buying patterns. Forecasting smooths out these bumps.

Just-in-Time (JIT) Pressures: Forecasting enables better planning for JIT manufacturing, reducing waste and improving cash flow.

Capital and Labor Optimization: With precise demand visibility, organizations can avoid over-investment in labor or machinery.

Forecasting enables planners to shift from reactive to proactive decision-making.

Unlocking Forecasting Potential with PlanetTogether APS

PlanetTogether APS provides a comprehensive, real-time solution that brings forecasting, scheduling, and capacity planning into a single environment. When integrated with systems like SAP, Oracle, Microsoft, Kinaxis, or Aveva, PlanetTogether becomes a powerhouse for predictive manufacturing.

Key Capabilities:

Dynamic Forecasting Models: PlanetTogether uses historical data and market indicators to project future demand scenarios.

Scenario Planning: Planners can simulate various market shifts and assess their impact on production lines, supply chains, and inventory.

Real-Time Visibility: Integration with ERP systems ensures planners always have the latest data on sales orders, material availability, and machine status.

Feedback Loops: Continuous updates from the shop floor refine forecasts, improving accuracy over time.

This feedback-rich environment creates a closed-loop planning system, reducing the guesswork and improving outcomes.

Integration in Action: PlanetTogether + Leading ERP Platforms

Let’s look at how integration elevates forecasting capabilities:

PlanetTogether + SAP

Integration with SAP S/4HANA allows for seamless data flow from demand planning modules into PlanetTogether's scheduling engine. Production planners can instantly convert sales forecasts into actionable production orders, aligned with shop floor realities.

PlanetTogether + Oracle

With Oracle SCM Cloud, PlanetTogether enhances end-to-end visibility into customer demand, supplier capabilities, and production bottlenecks. The result is adaptive forecasting that evolves with your supply chain.

PlanetTogether + Microsoft Dynamics

When connected to Microsoft Dynamics 365, PlanetTogether pulls real-time financials, sales, and procurement data. This enables a tighter integration between strategic forecasting and operational planning.

PlanetTogether + Kinaxis

Kinaxis RapidResponse is renowned for its "what-if" analysis features. Integrating it with PlanetTogether extends scenario analysis to the shop floor, helping planners assess capacity implications before committing to production runs.

PlanetTogether + Aveva

Aveva’s strength in industrial operations and asset performance management complements PlanetTogether’s scheduling prowess. Forecasting is not just about demand—it’s also about predicting asset availability, which this integration supports beautifully.

The Competitive Advantage of Forecast-Driven Planning

Forecasting market expectations isn’t just a planning function—it’s a competitive advantage. Here's how production planners benefit:

Better Service Levels: Faster, more reliable deliveries increase customer satisfaction and loyalty.

Inventory Optimization: Avoid stockouts and overstock situations, improving working capital management.

Agility: Quickly pivot production lines to match market fluctuations or new customer orders.

Cost Reduction: Smarter resource allocation reduces overtime, expedites, and material waste.

Companies that embed forecasting into their APS strategy consistently outperform peers in on-time delivery, inventory turnover, and operating margins.

Common Challenges and How to Overcome Them

While the benefits are compelling, challenges remain:

Data Silos: Disconnected systems hinder accuracy. Integration is key.

Forecast Accuracy: Overly optimistic or conservative forecasts skew planning. Continuous improvement loops and machine learning help.

Change Resistance: Getting teams to adopt new tools takes time. Start with high-impact pilot projects to build trust.

PlanetTogether’s intuitive interface and compatibility with major ERP platforms minimize these adoption hurdles, making it easier to build a robust forecasting culture.

Production Planners are no longer simply schedulers—they are strategic enablers of business resilience. Forecasting market expectations through tools like PlanetTogether, especially when integrated with platforms like SAP, Oracle, Microsoft, Kinaxis, or Aveva, transforms the production function from reactive to responsive, from isolated to integrated.

In a world where precision and speed define success, leveraging technology to predict and plan is not just beneficial—it’s essential.

Ready to Forecast with Confidence?

Start aligning your production with real market demand. Explore how PlanetTogether APS can revolutionize your planning strategy through seamless ERP integration. Contact us today to learn more about how we can help you achieve your goals and drive success in your industry.