Predictive Quality Control: A Strategic Imperative

With the competitive landscape becoming more cutthroat and customer expectations soaring higher than ever, the need for predictive quality control has emerged as a game-changer. For Operations Directors steering the ship in these environments, mastering predictive quality control isn't merely advantageous—it's a strategic imperative.

In this blog post, we'll look into the significance of predictive quality control in industrial manufacturing, exploring its benefits, challenges, and the pivotal role it plays in driving operational excellence. Moreover, we'll spotlight how integrating advanced planning and scheduling (APS) solutions like PlanetTogether with ERP, SCM, and MES systems such as SAP, Oracle, Microsoft, Kinaxis, and Aveva can supercharge your predictive quality control efforts.

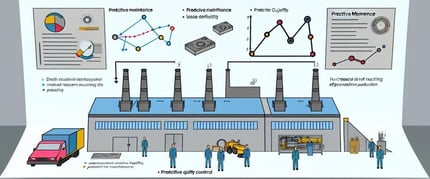

Predictive Quality Control

Quality control has long been synonymous with reactive measures—detecting and rectifying defects post-production. However, in today's dynamic manufacturing landscape, this reactive approach is no longer sufficient. Manufacturers must pivot towards a proactive strategy: predictive quality control.

Predictive quality control leverages advanced analytics, machine learning, and real-time data to forecast potential defects, identify root causes, and preemptively address them before they escalate into costly issues. By analyzing historical data, monitoring process parameters, and integrating predictive models, manufacturers can anticipate quality deviations, optimize processes, and uphold impeccable standards throughout the production lifecycle.

Benefits of Predictive Quality Control

Enhanced Product Quality: By predicting and preventing defects before they occur, manufacturers can deliver products that consistently meet or exceed customer expectations, bolstering brand reputation and fostering customer loyalty.

Cost Reduction: Proactively addressing quality issues minimizes scrap, rework, and warranty claims, leading to significant cost savings and improved profitability.

Increased Operational Efficiency: Predictive quality control optimizes manufacturing processes, reduces downtime, and enhances resource utilization, driving operational efficiency and throughput.

Regulatory Compliance: By maintaining stringent quality standards and preemptively addressing deviations, manufacturers can ensure compliance with regulatory requirements and industry standards.

Strategic Decision-Making: Access to real-time quality insights empowers Operations Directors to make data-driven decisions, optimize resource allocation, and continuously improve processes.

Challenges and Considerations

While the benefits of predictive quality control are undeniable, implementing and operationalizing these systems come with their own set of challenges:

Data Integration: Integrating disparate data sources—from production systems to quality management software—is essential for building accurate predictive models. However, data silos, incompatible formats, and varying quality standards can hinder seamless integration efforts.

Model Accuracy: Predictive models are only as good as the data they're trained on. Ensuring model accuracy requires clean, relevant data and ongoing validation and refinement to adapt to evolving production conditions.

Change Management: Embracing predictive quality control necessitates a cultural shift within the organization, from reactive to proactive quality management. Effective change management strategies are crucial to garner buy-in from stakeholders and drive adoption across the organization.

Resource Allocation: Deploying predictive quality control systems requires significant investments in technology, talent, and infrastructure. Operations Directors must carefully allocate resources and prioritize initiatives based on potential ROI and strategic alignment.

Integrating APS Solutions with ERP, SCM, and MES Systems

The seamless integration of APS solutions like PlanetTogether with ERP, SCM, and MES systems is instrumental in unlocking the full potential of predictive quality control. By bridging the gap between planning, execution, and quality management, these integrated systems enable Operations Directors to:

Real-Time Visibility: Integration provides real-time visibility into production schedules, inventory levels, and quality metrics, empowering Operations Directors to proactively identify and address quality deviations as they occur.

Data Consistency and Accuracy: By synchronizing data across systems, integration minimizes errors, eliminates duplicate data entry, and ensures consistency and accuracy throughout the production process.

Streamlined Workflows: Integrated systems automate data exchange and streamline workflows, reducing manual intervention, and accelerating decision-making cycles.

Holistic Analysis: By consolidating data from disparate sources, integrated systems facilitate holistic analysis, enabling Operations Directors to gain deeper insights into the factors impacting quality and drive continuous improvement initiatives.

Scalability and Flexibility: Integrated systems are scalable and adaptable, allowing manufacturers to seamlessly expand operations, integrate new technologies, and respond to changing market dynamics.

In the hyper-competitive manufacturing landscape, predictive quality control isn't just a buzzword—it's a strategic imperative. For Operations Directors tasked with driving operational excellence, mastering predictive quality control is paramount to sustaining competitiveness, enhancing product quality, and maximizing profitability.

By embracing advanced planning and scheduling solutions like PlanetTogether and integrating them with ERP, SCM, and MES systems, Operations Directors can unlock the full potential of predictive quality control. From real-time visibility and streamlined workflows to holistic analysis and scalability, integrated systems empower manufacturers to proactively identify, prevent, and address quality deviations, ensuring impeccable standards throughout the production lifecycle.

In the journey towards predictive quality control, integration isn't just a means to an end—it's the cornerstone of operational excellence and sustainable growth. Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.