Resilience at Scale: How APS and Cloud ERP Integration Empower Adaptive Operations in Medical Manufacturing

Medical manufacturing is under constant pressure — from sudden supply chain shocks and raw material shortages to shifting regulatory demands and surging market expectations. For Operations Directors, the challenge is not just to maintain steady production but to build resilience at scale: creating operations that can flex, adapt, and respond swiftly without sacrificing efficiency or compliance.

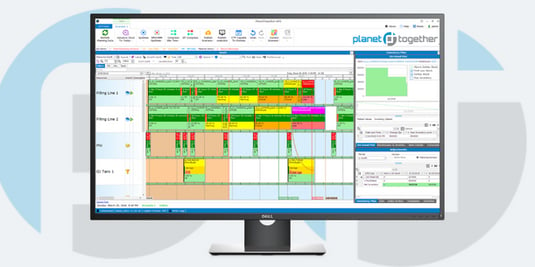

Advanced Planning and Scheduling (APS) tools like PlanetTogether, when integrated with cloud-based ERP systems such as SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva, provide a powerful solution to this challenge. Together, they enable medical manufacturers to synchronize planning, boost real-time visibility, and strengthen their adaptive capacity.

This blog explores how integrating APS and cloud ERP transforms operational resilience — and why Operations Directors should prioritize this synergy in their digital strategy.

The Resilience Imperative in Medical Manufacturing

Unlike many industries, medical manufacturing operates within razor-thin margins for error. Product quality is life-critical; supply chain disruptions can directly affect patient outcomes; and regulatory compliance is non-negotiable. Additionally, global events like the COVID-19 pandemic have revealed just how fragile traditional, linear supply chains can be.

Operations Directors are increasingly asked to do more with less:

Manage fluctuating demand across diverse product lines.

Navigate complex, often global supplier networks.

React instantly to disruptions while maintaining production stability.

Ensure all processes meet stringent regulatory and traceability requirements.

Building resilience at scale requires not just better communication but system-level integration — where planning, production, and supply chain systems work seamlessly together. That’s where the APS and cloud ERP combination comes in.

What Is APS and Why Does It Matter?

Advanced Planning and Scheduling (APS) systems like PlanetTogether help manufacturers move beyond static, manual planning. APS tools enable:

Real-time production scheduling that dynamically responds to shifts in demand, machine availability, or labor constraints.

Scenario planning and what-if analysis, allowing operations teams to simulate and evaluate the impact of disruptions or adjustments.

Optimization of resources — balancing materials, machines, and labor for the best throughput and minimal waste.

However, APS doesn’t operate in a vacuum. Its power is amplified when it connects with the enterprise-wide data and workflows housed within a cloud ERP system.

The Role of Cloud ERP in Adaptive Operations

Cloud ERP platforms — such as SAP S/4HANA Cloud, Oracle Cloud ERP, Microsoft Dynamics 365, Kinaxis RapidResponse, or Aveva’s cloud solutions — serve as the digital backbone for modern manufacturers. They provide a unified, real-time view of critical business functions: finance, procurement, inventory, compliance, and beyond.

By hosting ERP in the cloud, medical manufacturers gain:

Scalability, allowing systems to flex with changing operational demands.

Always-on connectivity, improving collaboration across sites and partners.

Real-time data access, enabling better decision-making at every level.

Lower IT overhead, freeing teams from managing on-premises infrastructure.

Yet ERP alone cannot handle the intricate details of day-to-day production sequencing and optimization — that’s where the integration with APS becomes game-changing.

Integration at the Core: PlanetTogether + Cloud ERP

When PlanetTogether APS integrates with cloud ERP systems, the result is a tightly connected, adaptive operational ecosystem. Here’s how this integration builds resilience:

Unified Planning and Execution

With APS-ERP integration, planning teams no longer work with stale or siloed data. Production schedules generated in PlanetTogether are immediately informed by live ERP data: inventory levels, order commitments, procurement status, and financial constraints. This ensures that scheduling decisions align with real-world business conditions — minimizing last-minute surprises and costly rescheduling.

Real-Time Disruption Response

Medical manufacturers can’t afford long lead times in responding to disruptions. Whether it’s a supply shortage, machine breakdown, or sudden surge in demand, PlanetTogether’s real-time scheduling engine, coupled with ERP’s live data feeds, enables instant, automated rescheduling. For Operations Directors, this means less firefighting and more proactive, confident adjustments.

Enhanced Visibility and Control

Integration provides a single source of truth across the organization. Operations teams can monitor performance metrics, production KPIs, and supply chain health through integrated dashboards, giving them early warning of potential bottlenecks. Cloud ERP’s enterprise-wide scope, combined with PlanetTogether’s detailed production insights, creates unmatched operational transparency.

Compliance and Traceability

Medical manufacturing is heavily regulated, and compliance failures can have dire consequences. Integrating APS and ERP ensures that scheduling and execution follow approved workflows, track materials and components accurately, and maintain digital records for audits. This reduces the risk of compliance lapses and strengthens quality assurance.

Scalable, Future-Proof Operations

Cloud ERP platforms enable manufacturers to scale operations seamlessly across multiple facilities, geographies, or product lines. Combined with PlanetTogether’s multi-plant scheduling capabilities, Operations Directors can coordinate complex, global production networks without sacrificing flexibility or performance — a critical advantage in today’s volatile environment.

Why Operations Directors Should Act Now

The competitive landscape for medical manufacturers is only getting tougher. Global supply chain risks, regulatory pressures, and market volatility aren’t going away — they’re intensifying. To survive and thrive, Operations Directors must ensure their facilities aren’t just efficient but adaptive.

By integrating PlanetTogether APS with a cloud ERP system, Operations Directors can:

Build flexible, scalable operations ready to pivot at a moment’s notice.

Eliminate data silos, creating seamless alignment across departments and partners.

Empower decision-making with real-time insights and scenario analysis.

Reduce risk, ensure compliance, and position the organization for long-term success.

Resilience at scale is no longer a nice-to-have — it’s a survival imperative for medical manufacturers. The integration of advanced scheduling tools like PlanetTogether with cloud ERP platforms such as SAP, Oracle, Microsoft, Kinaxis, or Aveva delivers the adaptability, visibility, and control needed to meet today’s challenges head-on.

For Operations Directors ready to lead their organizations into a more agile and resilient future, the message is clear: integrate, optimize, and adapt — or risk being left behind.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.