Tariff Volatility and Material Sourcing: APS for Cost-Responsive Planning

In packaging and containers manufacturing, Production Planners face an increasingly unpredictable challenge: global tariff volatility. As trade tensions shift and new regulations emerge, sourcing materials across international markets becomes a high-stakes balancing act. The need to secure raw materials at competitive prices while maintaining production flow has never been more complex — or more critical.

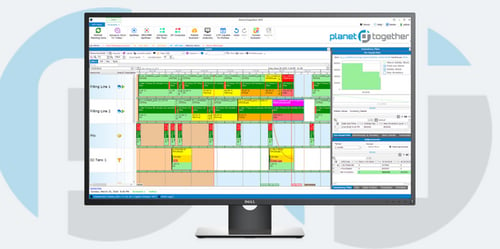

Advanced Planning and Scheduling (APS) systems like PlanetTogether, especially when integrated with enterprise platforms such as SAP, Oracle, Microsoft, Kinaxis, or Aveva, offer Production Planners powerful tools to navigate this storm. By enabling cost-responsive planning, manufacturers can proactively adjust sourcing, scheduling, and production strategies to keep operations resilient and profitable despite fluctuating tariffs.

This blog explores how APS solutions help Packaging and Containers Manufacturing facilities manage tariff risks and material sourcing challenges — and why integrating these tools into broader ERP or supply chain systems is a game-changer for Production Planners.

The Tariff Challenge in Packaging Manufacturing

Packaging manufacturers rely heavily on imported materials: plastics, aluminum, paperboard, adhesives, inks, and coatings, to name a few. Tariffs on these materials can swing dramatically due to:

International trade agreements or disputes

New environmental or compliance regulations

Sudden political shifts or economic sanctions

For Production Planners, this volatility means that procurement costs can change overnight, threatening margins and complicating long-term contracts. It also introduces uncertainty into production schedules, especially when sudden cost increases or sourcing restrictions force a scramble for alternative suppliers or substitute materials.

Without a system to dynamically model, analyze, and optimize the impact of these shifts, planners are often left reacting too late — leading to cost overruns, missed deadlines, and supply disruptions.

APS as the Engine of Cost-Responsive Planning

Advanced Planning and Scheduling systems like PlanetTogether help Production Planners take a proactive approach to tariff and sourcing challenges by:

Mapping multi-supplier and multi-site scenarios: APS allows planners to simulate different supplier options, lead times, and cost structures, comparing not just material prices but the total landed cost (including tariffs, transportation, and handling).

Real-time cost impact analysis: Instead of relying on static spreadsheets, APS tools pull in live or regularly updated data, allowing planners to see immediately how a new tariff or cost change affects production budgets and profitability.

Flexible scheduling across material constraints: If a key material suddenly becomes too expensive or restricted, APS can rapidly re-optimize schedules to use alternate materials or reschedule jobs at different facilities, minimizing downtime.

Integration with ERP systems for synchronized planning: By connecting PlanetTogether APS with platforms like SAP, Oracle, Microsoft, Kinaxis, or Aveva, planners can align detailed production schedules with higher-level business data — ensuring that financial, procurement, and supply chain teams all work from the same cost-aware plan.

Key Benefits of PlanetTogether APS Integration for Tariff-Responsive Planning

Let’s break down why the integration between PlanetTogether APS and major ERP or supply chain platforms is essential for effective tariff management.

End-to-End Visibility

When PlanetTogether integrates with systems like SAP S/4HANA or Oracle Cloud SCM, it doesn’t just handle shop-floor scheduling; it taps into broader financial, procurement, and supplier data. This gives Production Planners a single pane of glass showing:

Current supplier price lists

Contract terms and volume discounts

Real-time tariff tables

Historical cost trends and forecasts

With this full-picture view, planners can make sourcing decisions that align with company-wide cost goals, not just local production targets.

Scenario Modeling for Smarter Sourcing

Imagine your main aluminum supplier faces a 25% import tariff increase next month. Do you shift to a domestic supplier with higher unit costs but no tariffs? Or should you pre-buy inventory to lock in current rates?

With PlanetTogether APS, planners can model multiple “what-if” scenarios, comparing cost, capacity, lead time, and risk factors. When integrated with Microsoft Dynamics 365 or Kinaxis RapidResponse, these models can automatically pull in supply chain constraints and demand forecasts — delivering recommendations that go beyond simple price comparisons.

Rapid Replanning and Execution

Tariff changes often happen with little warning. Planners need tools that can re-optimize schedules in minutes, not days.

By connecting PlanetTogether APS with systems like Aveva Manufacturing Execution System (MES) or SAP Integrated Business Planning (IBP), companies can automate the handoff between planning and execution. If a material shortage triggers a reschedule, the APS system can immediately update production lines, notify procurement, and adjust shipping commitments — all without manual spreadsheet firefighting.

Enhanced Collaboration Across Teams

Tariff management isn’t just a production problem; it spans finance, procurement, logistics, and sales. Integrating PlanetTogether APS with enterprise systems enables cross-functional collaboration, ensuring that:

Finance teams understand how tariff-driven sourcing changes impact margins

Procurement teams can quickly pivot to alternate suppliers

Logistics teams can reroute shipments in response to new sourcing locations

Sales teams can adjust pricing strategies based on real production costs

This connected approach turns the APS from a siloed scheduling tool into a strategic asset for the entire organization.

Practical Example: Packaging Company Under Tariff Pressure

Consider a packaging manufacturer sourcing coated paperboard from Asia. Due to new tariffs, the cost per ton increases by 15%, threatening to wipe out the company’s margins on several high-volume SKUs.

Without APS, the planner would need to:

Manually calculate new costs

Scramble to identify domestic alternatives

Evaluate if production can switch to alternate materials

Rebuild schedules around the new supply chain realities

With PlanetTogether APS, integrated into their Oracle ERP, the planner can:

Run a cost simulation across global suppliers, factoring in tariffs and lead times.

Identify that switching 30% of volume to a domestic supplier avoids the tariff hit while keeping unit costs reasonable.

Re-optimize the production schedule to blend materials without exceeding line capacity or violating customer specs.

Generate updated procurement orders and shipping plans, synchronized with Oracle’s purchasing and logistics modules.

This fast, data-driven response turns a potential margin disaster into a manageable adjustment — preserving customer commitments and financial performance.

Preparing for the Future: Building Tariff Resilience

Tariff volatility is not going away. In fact, as global supply chains become more intertwined and geopolitical risks rise, Production Planners will face even more complex sourcing puzzles.

To stay ahead, Packaging and Containers Manufacturers need to:

✔ Invest in integrated planning systems that connect APS tools like PlanetTogether with ERP, supply chain, and execution platforms.

✔ Continuously update sourcing data within APS models to reflect the latest tariff rates, supplier costs, and material availability.

✔ Train planning teams to use scenario analysis and cost modeling as core parts of their daily workflow, not just emergency tools.

By embedding APS into the heart of sourcing and production planning, companies can move from reactive crisis management to proactive cost-responsive planning — turning tariff challenges into opportunities for competitive advantage.

For Production Planners in Packaging and Containers Manufacturing, tariff volatility no longer needs to be a crippling risk. With the right Advanced Planning and Scheduling systems — particularly PlanetTogether, integrated with enterprise platforms like SAP, Oracle, Microsoft, Kinaxis, or Aveva — planners gain the agility, visibility, and analytical power to respond quickly and smartly.

The result? Smoother material sourcing, optimized costs, and resilient production schedules that help the company thrive, even in the face of unpredictable global trade shifts.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.