Additive Manufacturing Meets Mass Customization: A Strategic Advantage for Packaging Production Planners

In the past, mass customization in packaging and containers manufacturing was considered too complex, too costly, and too inefficient to implement at scale. But today, with the advent of additive manufacturing (AM) and intelligent planning tools like PlanetTogether APS integrated with SAP, Oracle, Microsoft, Kinaxis, or Aveva, the equation has changed.

For Production Planners in the packaging industry, this convergence presents a pivotal opportunity. Not only can you manage complex, custom orders more effectively, but you can also deliver them faster, reduce waste, and drive bottom-line growth—without compromising on flexibility.

What Is Additive Manufacturing in Packaging?

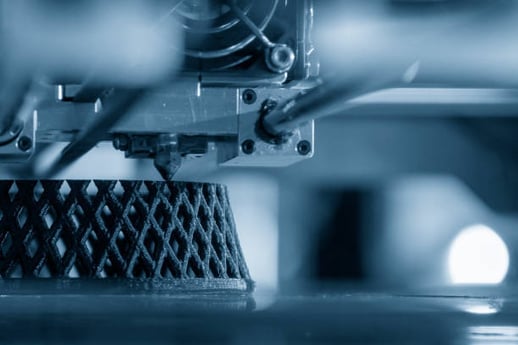

Additive manufacturing, also known as 3D printing, involves creating products layer-by-layer based on digital designs. While AM is commonly associated with aerospace, automotive, and medical applications, it is gaining traction in packaging and containers manufacturing, particularly for custom tooling, molds, short-run packaging components, and prototyping.

In this context, AM serves a dual purpose:

Tooling and mold innovation: Quickly developing custom molds for new packaging designs.

Direct production: Producing lightweight packaging inserts or specialty parts for limited-run or customized packages.

The Rise of Mass Customization in Packaging

Mass customization refers to the ability to produce goods that are tailored to individual customer needs—but at or near mass production efficiencies.

In the packaging sector, this might include:

Limited-edition promotional packaging.

Custom packaging for regional markets.

Short-run SKUs tailored to online retail requirements.

Additive manufacturing enables these use cases, but its success depends on tight production scheduling, material planning, and coordination across digital platforms—a challenge for even the most experienced Production Planner.

The Role of PlanetTogether APS in Additive Manufacturing Scheduling

Advanced Planning and Scheduling (APS) systems like PlanetTogether play a vital role in ensuring that AM-based operations are executed efficiently. When integrated with SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva, PlanetTogether provides planners with:

Real-Time Visibility

Through integration with ERP and MES platforms, PlanetTogether provides a unified view of:

Available raw materials (e.g., filaments, polymers).

Machine availability (e.g., 3D printers, post-processing units).

Operator schedules and shifts.

This live visibility allows for quick response to changeovers, urgent orders, or machine downtimes.

Intelligent Job Sequencing

Mass customization introduces variability into the production line. PlanetTogether uses optimization algorithms to sequence AM jobs based on:

Priority rules.

Similarity in material types.

Post-processing requirements.

This reduces material waste and improves throughput.

Resource Load Balancing

By integrating with SAP or Kinaxis, PlanetTogether can analyze capacity constraints not just on printers, but on upstream and downstream processes—such as mold design teams or quality inspection stations.

This helps Production Planners avoid bottlenecks, which are common in highly customized production environments.

Why ERP Integration Is Essential

To enable AM at scale, it’s not enough to adopt 3D printers. You need a fully digital workflow. That’s where ERP integration becomes crucial.

With SAP or Oracle:

BOMs and routings for custom SKUs are automatically generated and updated based on customer specs.

Material requirements are calculated precisely for each job.

Production orders are fed into PlanetTogether for optimization and scheduling.

With Microsoft Dynamics:

Real-time updates on order status allow sales and planning to remain aligned.

Custom templates can be quickly adjusted and linked to AM production cycles.

With Kinaxis:

Demand forecasts for customized packaging can be more accurately integrated into overall supply chain planning.

What-if simulations help planners test different customization strategies under varying lead times and resource constraints.

With Aveva:

MES data from the production floor (e.g., printer status, quality control results) is fed back into planning systems.

Feedback loops ensure continuous improvement of AM workflows.

Benefits of AM and APS Integration for Production Planners

When additive manufacturing is supported by robust planning tools, Production Planners gain:

Greater Agility

Custom packaging requests can be fulfilled without disrupting baseline production schedules.

Improved Forecast Accuracy

With Kinaxis or SAP feeding demand signals and PlanetTogether dynamically adjusting production sequences, planners can better forecast material and capacity needs.

Reduced Inventory Levels

On-demand production reduces the need for warehousing pre-made custom components or tools.

Enhanced Customer Satisfaction

Faster turnarounds on tailored packaging improve customer experience and enable brands to innovate.

Additive manufacturing is not just a futuristic novelty in packaging—it’s a strategic enabler of mass customization. And the linchpin for making it all work is intelligent production planning. With the power of PlanetTogether APS and seamless ERP/MES integration, Production Planners are uniquely positioned to turn variability into a competitive advantage.

Mass customization is here—and your planning tools are the key to unlocking its potential. Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.