Batch vs. Continuous Production: APS Strategies to Maximize Output in Chemical Manufacturing

In chemical manufacturing, the choice between batch production and continuous production is not just a technical decision—it is a strategic one. Each approach comes with its own operational complexities, cost implications, and production dynamics. For Manufacturing IT leaders in chemical plants, navigating this choice while ensuring maximum output requires sophisticated tools and intelligent systems.

One such powerful enabler is Advanced Planning and Scheduling (APS) software, like PlanetTogether, especially when integrated seamlessly with enterprise systems such as SAP, Oracle, Microsoft, Kinaxis, or Aveva. These integrations allow chemical manufacturers to go beyond basic scheduling and enter the realm of true optimization, balancing capacity, raw material availability, equipment readiness, and customer demand.

In this blog, we explore how APS strategies tailored for batch and continuous production can significantly maximize output, reduce waste, and improve operational agility.

Understanding Batch and Continuous Production

Before diving into APS strategies, it’s essential to understand the core differences between these two production modes:

Batch Production:

Products are manufactured in specific, measurable quantities or “batches.” This mode is common for specialty chemicals, adhesives, coatings, and pharmaceuticals, where formulations vary, or flexibility is required to switch products frequently. Batch production offers customization and precise control but comes with changeover times, equipment cleaning, and scheduling challenges.

Continuous Production:

This mode involves uninterrupted production, often seen in large-scale commodity chemicals like petrochemicals, polymers, or fertilizers. Continuous processes are highly efficient, designed for consistent, high-volume outputs with minimal variation, but they demand tightly controlled conditions and high reliability.

Both models have their unique optimization challenges, and this is where APS comes into play.

The Role of APS in Batch and Continuous Production

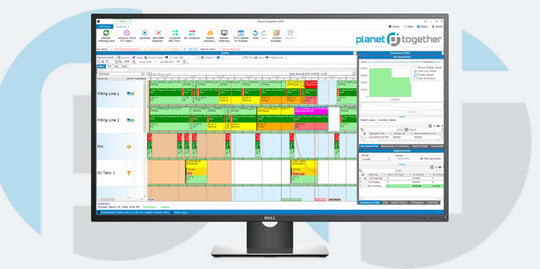

APS systems like PlanetTogether provide a dynamic, data-driven layer of intelligence over the manufacturing execution systems (MES) and enterprise resource planning (ERP) systems such as SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva.

By integrating across these systems, APS allows manufacturers to:

Generate real-time, optimized schedules

Balance demand and capacity

Minimize bottlenecks and changeovers

Synchronize production with supply chain inputs and customer orders

For Manufacturing IT teams, enabling this integration means breaking down silos between systems, ensuring data integrity, and providing planners and schedulers with intuitive interfaces and actionable insights.

APS Strategies for Batch Production

Batch operations face specific challenges, including frequent product changeovers, strict recipe adherence, material compatibility, and equipment cleaning. To maximize output, APS systems apply several key strategies:

Optimized Changeover Scheduling

PlanetTogether APS can group similar production orders to minimize changeover times. For example, scheduling all batches using similar solvents or raw materials sequentially reduces cleaning requirements and maximizes uptime.

Material and Equipment Constraints Management

Batch production often faces limitations on material availability or specific reactor capacities. By integrating with SAP or Oracle, the APS can ensure that planned batches align with real-time inventory data, avoiding delays or stoppages due to missing inputs.

Flexible Slot Management

APS systems allow planners to dynamically adjust batch slots based on late-breaking customer orders or urgent priorities. This flexibility is vital in specialty chemical manufacturing, where responsiveness can be a competitive edge.

Batch Traceability and Compliance

For highly regulated sectors, APS integration with ERP systems ensures traceability from raw material to finished product, supporting compliance audits and quality controls.

APS Strategies for Continuous Production

Continuous production lines rely on maximizing throughput, maintaining steady-state operations, and avoiding costly shutdowns. APS strategies here focus on:

Capacity Balancing Across Lines

PlanetTogether APS can simulate multiple production scenarios, identifying optimal product mixes and running conditions to maximize line utilization without overloading downstream processes.

Predictive Maintenance Integration

By connecting APS with MES and maintenance systems (via Microsoft or Aveva), Manufacturing IT can ensure that production schedules account for planned maintenance windows, preventing unexpected breakdowns and maximizing uptime.

Energy Optimization

Continuous production consumes vast amounts of energy. APS can integrate with energy management modules within SAP or Oracle to adjust production rates or shifts to take advantage of lower energy costs or reduce peak load charges.

Real-Time Response to Disruptions

When upstream or downstream disruptions occur, APS helps reschedule or reroute production, maintaining overall output despite local disturbances.

The Power of Integration: APS + ERP

The real game-changer for Manufacturing IT lies in integration. Without integration, APS becomes just another isolated tool. But when connected seamlessly to SAP, Oracle, Microsoft, Kinaxis, or Aveva, APS transforms into the central nervous system of the plant.

Here’s how integration amplifies APS capabilities:

Unified Data Source:

Integrated APS systems pull real-time data from ERP systems, ensuring that scheduling decisions are always based on the latest inventory, demand forecasts, and capacity constraints.

Cross-Functional Visibility:

Operations, supply chain, sales, and maintenance teams can all view synchronized production plans, reducing miscommunication and aligning goals across departments.

Automated Adjustments:

Integrated APS can automatically adjust production schedules in response to changes in supply, demand, or equipment status, minimizing manual interventions and delays.

Advanced Analytics and Reporting:

By feeding APS data back into ERP systems, companies can perform advanced analytics—identifying trends, inefficiencies, and improvement opportunities over time.

For Manufacturing IT leaders, driving these integrations often means deploying robust middleware, ensuring API compatibility, managing data quality, and championing change management across departments.

Maximizing Output: Best Practices for Manufacturing IT

To fully leverage APS strategies for both batch and continuous production, Manufacturing IT teams should adopt several best practices:

Prioritize System Integration: Ensure that PlanetTogether APS integrates smoothly with your core ERP, MES, and maintenance systems to avoid data silos.

Invest in Data Accuracy: Garbage in, garbage out. High-quality scheduling relies on accurate master data, BOMs, routings, and inventory records.

Enable User-Friendly Interfaces: Empower planners, schedulers, and operators with intuitive dashboards and interfaces to visualize schedules, constraints, and KPIs.

Adopt a Continuous Improvement Mindset: Use APS not just for scheduling but for ongoing optimization. Regularly analyze scheduling outcomes and adjust rules, constraints, and priorities.

Ensure Cybersecurity: Integration increases the system’s attack surface. Work closely with cybersecurity teams to secure APIs, ensure proper access controls, and monitor for anomalies.

In chemical manufacturing, whether you run batch or continuous operations, the goal is the same: maximize output, minimize costs, and maintain flexibility.

APS systems like PlanetTogether, when integrated with robust ERP platforms like SAP, Oracle, Microsoft, Kinaxis, or Aveva, provide Manufacturing IT leaders with the tools they need to orchestrate complex production environments with precision. By applying tailored strategies for each production mode and ensuring seamless system integration, chemical manufacturers can elevate their performance, drive efficiency, and strengthen their market position.

For Manufacturing IT teams, the opportunity is clear: harness the full power of APS and integrated scheduling to lead your plant into a future of smart, agile, and optimized operations.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.