In supply chain management, bottlenecks can present repetitive obstacles in production for most manufacturing and production facilities and will hinder the optimization of output and profitability.

In supply chain management, bottlenecks can present repetitive obstacles in production for most manufacturing and production facilities and will hinder the optimization of output and profitability.

When process input is received at a quicker pace than process output, you may have a bottleneck or even multiple bottlenecks constraining your throughput.

Bottlenecks can cause delays in production and can be costly for the company if they are not resolved. No matter how well your manufacturing operations are running, you can usually identify bottlenecks that are reducing the overall production capacity.

What is a Bottleneck?

A bottleneck can be defined as a step or operation that has limited capacity and reduce the capacity of the entire production chain. Bottlenecks and constraints can be defined as:

- Process step exceeding 100% utilization

- Capacity dropping below or equaling takt time

- Capacity dropping below or equaling demand

Locating bottlenecks is a vital troubleshooting practice for production facilities looking to improve their operations. This can be an ongoing procedure in production facilities and operations.

The presence of bottlenecks can cause:

- Delays in production

- Low customer satisfaction

- Stress on employees

- Excess work-in-progress items

Increasing flow by locating the bottleneck constraints in your production or manufacturing operation is one step in optimizing your overall operational efficiency. To do this, it is essential that you gain visibility into your manufacturing operations to identify and eliminate bottlenecks.

Visibility is Key

In the process of identifying and eliminating bottlenecks, visibility is key. This is because it is impossible to fix what you can’t see.

Having access to accurate production data can help manufacturers overcome the difficulty of locating bottlenecks. By looking through the available production data, you can locate areas of production that are not reaching the forecasted productivity levels. If the amount of output or production is below the amount forecasted in your production plan, then there are possible bottlenecks preventing the operation from reaching its higher output/throughput potential.

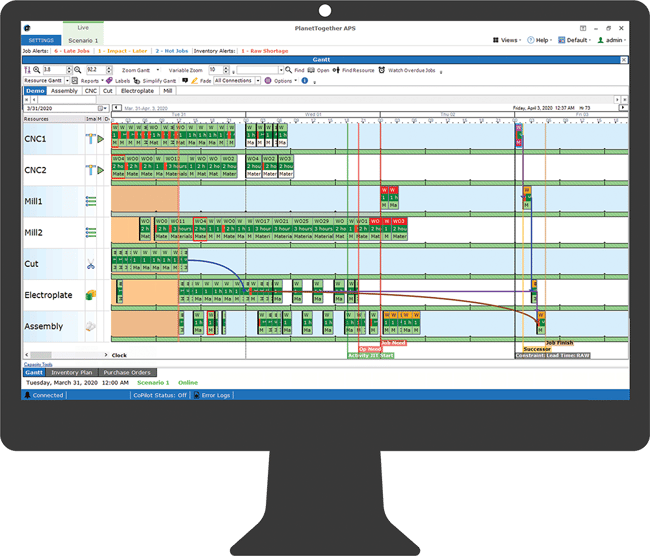

Gantt chart production scheduling can also increase the visibility within your production operations. These charts allow manufacturers to see all of their resources on one screen and provides a better understanding of how operations affect downstream operations.

The great thing about PlanetTogether APS is that all machines can be grouped together on one screen. You know immediately how each machine impacts the others and their basic correlation to the whole schedule, not just for the current week but for days, weeks, or months out . . .very organized and coordinated.

JAIME OZUNA, PRODUCTION SCHEDULER, ATLANTIC COFFEE

Bottleneck & Constraint Remediation

Bottleneck analysis involves locating the source of the bottleneck and coming up with a solution to eliminate it within the production system. There are a series of steps that a company can take to overcome the constraint and subsequently increase the overall capacity.

- Locate the Source of the Bottleneck - The first step in bottleneck remediation is to locate the source of the constraint. After identifying the bottleneck constraint, plant managers may conduct an analysis on the bottleneck to determine what is truly causing it.

- Determine the Type of Bottleneck - When the bottleneck constraint is identified, it is declared a long-term or a short-term bottleneck. Short-term bottlenecks are usually isolated incidents that are resolved within a period of time. On the other hand, long-term bottlenecks are caused by recurring issues that cause negative impacts on the production schedule.

- Resolve Bottlenecks - Once you have identified the long-term bottlenecks that are negatively impacting the production operations, you can find the best solution to resolve it. The solution chosen will depend on what is causing the bottleneck as not all solutions may be applicable. For example, a bottleneck caused by a machine running at a slower speed that it should can be remedied by scheduling maintenance and repair work on it. Alternatively, investing in a machine with the same capabilities will also increase capacity for that production step. However, adding more labor resources may not be a suitable option to remove the bottleneck.

Major performance improvements will result from the identification and elimination of bottlenecks that continuously slow down the manufacturing flow.

Advanced Planning & Scheduling (APS) and Real-Time Bottleneck Targeting

A manufacturing bottleneck constrains the entire organization and lowers the production capacity of the facility. Identifying and eliminating bottlenecks within your manufacturing operation can be a challenging feat for any manufacturer.

However, PlanetTogether’s Advanced Planning and Scheduling system has a multitude of features that can make this process easier. PlanetTogether APS is integrated with your existing ERP system to allow you to create realistic production schedules that account for production limitations.

In addition, this software will quickly identify production bottlenecks before problems occur and allow you to adjust production in advance. An integrated APS software can greatly reduce the response and remediation time required to deal with constraints and bottlenecks in production. Your company’s performance will be optimized so that you can deliver items on time and maximize your profits.

PlanetTogether’s Advanced Planning and Scheduling (APS) Software

Advanced Planning and Scheduling Softwares have become a must for modern-day manufacturing operations as customer demand for increased product assortment, fast delivery, and downward cost pressures become prevalent. These systems help planners save time while providing greater agility in updating ever-changing priorities, production schedules, and inventory plans. APS Systems can be quickly integrated with an ERP/MRP software to fill the gaps where these systems lack planning and scheduling flexibility, accuracy, and efficiency.

With PlanetTogether APS you can:

- Create optimized schedules that balance production efficiency and delivery performance

- Maximize throughput on bottleneck resources to increase revenue

- Synchronize supply with demand to reduce inventories

- Provide company-wide visibility to resource capacity

- Enable scenario data-driven decision making

The implementation of an Advanced Planning and Scheduling (APS) Software will take your manufacturing operations to the next level of production efficiency by taking advantage of the operational data you already possess in your ERP system. APS is a step in the right direction of efficiency and lean manufacturing production enhancement. Try out a demo!

Related What-If Scenario Video

APS Resources