3 Steps of Capacity Planning in Manufacturing (Requirements to Future)

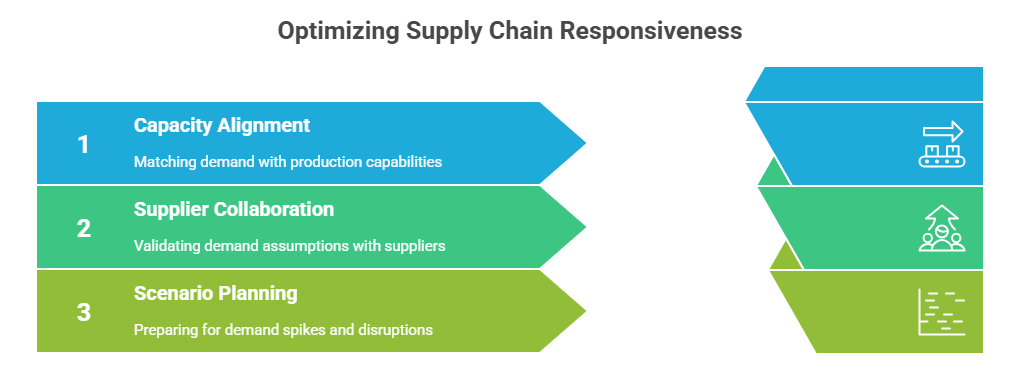

Stop delays and idle machines. Use a 3-step capacity planning process to match demand to resources, model scenarios, and build realistic schedules.

See how operations leaders use demand planning, forecasting, and finite scheduling to build resilient supply chains—using an aerospace & defense example.

Operations management shapes supply chains by synchronizing three levers: demand planning, forecasting, and finite scheduling. Demand plans must reflect real, finite capacity so commitments are deliverable. Forecasts should combine historical program data with current contract signals, supplier readiness, and labor availability. Finite scheduling then sequences work around bottlenecks, downtime, setup times, and material readiness. APS systems integrate these views and enable what-if scenarios.

Every decision you make in operations sends ripples across the supply chain. The way you plan demand, build forecasts, and schedule production determines not only whether commitments are met, but also how efficiently resources are used and how resilient the supply chain becomes.

The challenge is that these decisions are made in an environment of constant pressure: shifting customer priorities, unpredictable supplier performance, and finite capacity on your shop floor. Navigating these forces requires more than managing today’s workload. It requires a system that connects demand, capacity, and scheduling into a single view so you can act with confidence.

Let’s pick an industry like aerospace and defense manufacturing to explore the three areas where operations leaders make the greatest impact: demand planning, forecasting, and finite scheduling.

In aerospace and defense, demand planning is the foundation of program execution. Whether you are coordinating parts for a multi-year aircraft program or balancing spares for defense contracts, the ability to align supply with true demand determines how well your supply chain functions.

The difficulty lies in volatility. Contract awards shift, budgets are revised, and urgent defense orders can appear without warning. If demand planning is not directly connected to capacity, you risk promising what cannot be delivered or stockpiling expensive inventory that ties up capital and risks obsolescence. Practical guidance:

Strong demand planning is not about locking in a perfect plan once. It is about continuously synchronizing contract-driven demand with the realities of constrained capacity.

Forecasting in aerospace and defense carries a unique weight. Multi-year projects mean forecasts are often based on long-range government budgets or global defense priorities. Yet programs cannot afford to wait for perfect clarity, operations leaders must prepare for uncertainty.

Take the case of a fighter jet assembly program. Forecasts must anticipate current build schedules, long-lead materials, spare parts demand, and the potential impact of political decisions on funding. Producing too few components risks contract penalties. Producing too many ties up millions of dollars in unused inventory.

Forecasting is also about resources. A shortage of certified machinists or delays from a critical composite supplier can derail a forecast just as much as shifts in customer demand. Practical guidance:

In a world where uncertainty is the only constant, disciplined forecasting gives you a structured way to prepare your supply chain without wasting capital or capacity.

If demand planning sets direction and forecasting prepares for uncertainty, finite scheduling ensures execution. In aerospace and defense, where bottlenecks are the norm, schedules that ignore real constraints create commitments that collapse when reality hits.

Consider composite curing autoclaves, which often have limited availability and long cycle times. If schedules assume infinite capacity, orders will stack up with no way to process them. Or think of skilled labor: without accurate scheduling, a shortage of certified welders can halt an entire production line.

Finite scheduling respects every constraint you face. It accounts for downtime, setup times, labor availability, and material readiness. By sequencing jobs to prioritize bottleneck resources and minimize wasted time, you create schedules that are achievable and resilient. Practical guidance:

Finite scheduling is not about rigidity. It is about precision. It gives you the clarity to deliver on commitments while maximizing the use of every constrained resource.

Demand planning, forecasting, and finite scheduling are not separate disciplines. They are interdependent levers that determine the strength of your supply chain. When aligned, they create a system that is resilient, efficient, and predictable. When disconnected, they create friction, wasted effort, and broken commitments.

Advanced planning and scheduling (APS) systems provide the integration needed to bring these elements together. By synchronizing demand with capacity, aligning forecasts with actual schedules, and running “what-if” scenarios, APS enables operations leaders to act with foresight rather than constantly react to crises.

The Future of Operations Leadership

The complexity of aerospace and defense will only grow. Programs will expand across global suppliers, demand signals will remain uncertain, and capacity constraints will persist. Success will not come from chasing efficiency alone, but from building systems that connect demand planning, forecasting, and finite scheduling into a single, reliable flow.

The future belongs to operations leaders who master this balance. By focusing on these three areas, you not only keep production moving, you create supply chains that are more responsive, more resilient, and better prepared for what comes next.

When demand planning and forecasting aren’t tied to finite capacity, operations teams end up overpromising, firefighting bottlenecks, and constantly reworking schedules. This is exactly why the post recommends aligning demand, constraints, and finite scheduling in one APS-driven flow—so decisions hold up on the shop floor.

The next step is making sure your organization is ready to get value from APS. The APS Readiness Score eBook gives you a practical way to benchmark your current state and identify what to fix first (data, process, metrics, and adoption).

Pinpoint readiness gaps in constraint data (BOMs, routings, setups, downtime, shifts) and bottleneck definition

Establish baseline metrics tied to outcomes like OTD, schedule stability, and CTP

Align executives and planners on shared success criteria (so “improvement” is measurable)

Build a practical adoption plan (DITL workflow mapping + change champions)

Leave with a clear set of “next steps” your team can execute before vendor evaluation

Already evaluating vendors? Request an APS demo

Every operations decision affects whether you meet commitments, how efficiently resources are used, and how resilient the supply chain becomes—especially under shifting priorities, supplier variability, and finite shop-floor capacity.

Demand planning aligns supply to “true demand” (e.g., contracts and program needs) and should be tied to finite capacity. Forecasting prepares for uncertainty by updating expectations as signals change and incorporating constraints like supplier and labor readiness.

Finite scheduling ensures execution by building schedules that respect real constraints—downtime, setup times, labor availability, and material readiness—so commitments don’t collapse when reality hits.

If demand is disconnected from capacity, you risk overpromising (missed delivery) or overbuilding (costly inventory and obsolescence). Connecting demand to finite capacity makes commitments realistic.

APS integrates demand, capacity, and scheduling into a single view—synchronizing demand with capacity, aligning forecasts to schedules, and enabling “what-if” scenarios so leaders can act with foresight instead of reacting.

Use the APS Readiness Scorecard to identify data/process gaps before vendor evaluation.

When demand planning and forecasting aren’t tied to finite capacity, operations teams end up overpromising, firefighting bottlenecks, and constantly reworking schedules. This is exactly why the post recommends aligning demand, constraints, and finite scheduling in one APS-driven flow—so decisions hold up on the shop floor.

The next step is making sure your organization is ready to get value from APS. The APS Readiness Score eBook gives you a practical way to benchmark your current state and identify what to fix first (data, process, metrics, and adoption).

Pinpoint readiness gaps in constraint data (BOMs, routings, setups, downtime, shifts) and bottleneck definition

Establish baseline metrics tied to outcomes like OTD, schedule stability, and CTP

Align executives and planners on shared success criteria (so “improvement” is measurable)

Build a practical adoption plan (DITL workflow mapping + change champions)

Leave with a clear set of “next steps” your team can execute before vendor evaluation

Already evaluating vendors? Request an APS demo

Stop delays and idle machines. Use a 3-step capacity planning process to match demand to resources, model scenarios, and build realistic schedules.

Understand the 5 supply chain functions—purchasing, demand planning, resource management, finite scheduling, and info workflow—and how APS aligns...

Resource scheduling in manufacturing is vital when it pertains to the development of a facility. Resource scheduling can efficiently schedule labor.

Stay ahead in the dynamic world of manufacturing with our blog, where PlanetTogether explores the latest industry trends, challenges, and innovations. From lean production techniques to smart factory transformations, our posts provide valuable insights tailored for manufacturers of all sizes.

Whether you're seeking strategic guidance or practical tips, this blog is your go-to resource for navigating the future of manufacturing.