Inventory Optimization through APS: Balancing Risk and Efficiency in 2025

Inventory Optimization through APS: Balancing Risk and Efficiency in 2025

In food and beverage (F&B) manufacturing, the year 2025 is bringing fresh challenges and opportunities to supply chain managers. Market volatility, changing consumer preferences, sustainability demands, and the relentless push for efficiency are all converging on one critical area: inventory optimization.

To succeed, it’s no longer enough to simply reduce inventory levels or chase just-in-time delivery. Instead, supply chain managers must balance risk and efficiency, ensuring that stock levels are resilient enough to absorb disruptions while being lean enough to avoid waste, overproduction, and excessive carrying costs. Advanced Planning and Scheduling (APS) tools like PlanetTogether, when integrated with enterprise systems like SAP, Oracle, Microsoft, Kinaxis, or Aveva, are proving essential for achieving this delicate balance.

Let’s explore how APS-driven inventory optimization is evolving in 2025 and how supply chain leaders can harness it to gain a competitive edge.

The 2025 Landscape: Complexity and Opportunity

The modern F&B supply chain has grown increasingly complex. Regional and global disruptions — from climate impacts on crop yields to geopolitical tensions affecting ingredient imports — are everyday risks. At the same time, consumers are demanding faster delivery, more customization, and higher transparency regarding sourcing and sustainability.

Supply chain managers must juggle:

Unpredictable demand patterns driven by seasonal trends and marketing pushes

Stringent regulatory requirements on product traceability and quality

Sustainability goals pushing for less food waste, better energy use, and greener packaging

Margin pressures from rising ingredient costs and tight competition

Against this backdrop, inventory optimization is no longer just a cost-cutting exercise — it’s a strategic function that directly impacts resilience, profitability, and customer satisfaction.

What Makes APS a Game-Changer for Inventory Optimization?

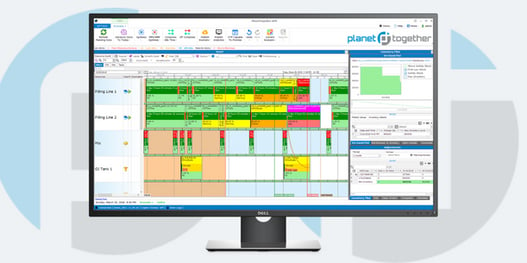

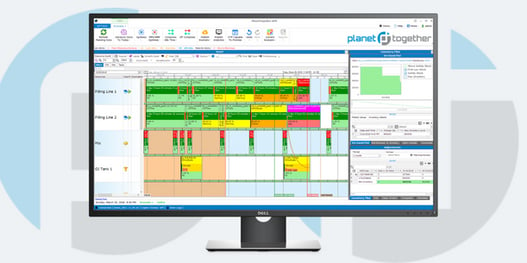

Traditional ERP systems provide foundational data management, but they often lack the dynamic modeling and optimization capabilities needed to fine-tune inventory in real time. That’s where APS platforms like PlanetTogether come in.

When integrated with leading ERPs (like SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva), APS solutions allow supply chain managers to:

Run multi-level inventory simulations considering material availability, production capacity, and customer demand

Model risk scenarios (e.g., supplier delays, transport bottlenecks, demand surges) to test the system’s resilience

Balance safety stock levels intelligently, avoiding both shortages and overstocking

Enable cross-department visibility between procurement, production, logistics, and sales

Dynamically reoptimize inventory plans when market or production conditions shift

In other words, APS extends the power of the ERP, adding a smart decision-making layer that makes inventory planning far more agile, data-driven, and risk-aware.

Balancing Risk and Efficiency: A Supply Chain Manager’s Playbook

To balance risk and efficiency through APS in 2025, supply chain managers should focus on four key strategies:

Implement Dynamic Safety Stock Policies

Rather than relying on fixed safety stock formulas, modern APS tools enable dynamic safety stock — adjusting buffer levels based on real-time risk assessments.

For example, if a particular supplier’s lead time reliability drops or a weather event threatens key ingredient supply, PlanetTogether can automatically recommend increasing safety stock for those SKUs, even while keeping lean inventory elsewhere. This avoids the old “blanket” approach of overstocking everything and instead targets risks precisely where they occur.

Integrate End-to-End Data for Visibility

With ERP integration, APS can tap into procurement schedules, production plans, supplier performance metrics, and even external signals (like market trends or weather forecasts) to inform inventory decisions.

A PlanetTogether integration with SAP, for instance, might pull supplier OTIF (on-time, in-full) performance data directly from SAP modules, allowing planners to adjust purchasing strategies or switch suppliers before shortages hit. Similarly, integration with Oracle or Kinaxis can feed demand forecasts directly into APS, ensuring inventory optimization aligns with the most current market intelligence.

Simulate Risk Scenarios and Stress-Test the Plan

APS platforms allow you to run simulations — asking “what if” questions to expose vulnerabilities before they become costly disruptions.

For instance, what happens if a raw material is delayed by two weeks? How much does a sudden demand spike strain current inventories? By stress-testing these scenarios, supply chain managers can proactively shore up weak points, adjusting sourcing plans, production schedules, or inventory buffers.

PlanetTogether’s integration with Microsoft Dynamics or Aveva provides a seamless data bridge between inventory, production, and maintenance systems, enabling even more robust risk modeling.

Synchronize Sustainability with Inventory Strategy

In 2025, optimizing inventory isn’t just about reducing costs — it’s also about meeting ESG (Environmental, Social, and Governance) targets. Excess inventory often leads to waste, particularly in perishable categories like dairy, meat, or fresh produce.

APS tools help by refining production schedules to minimize overproduction, extending shelf life through smarter sequencing, and ensuring that the right quantities are produced at the right time. Integration with ERP systems means that sustainability data — such as carbon emissions per shipment or waste percentages — can be factored directly into planning models, aligning inventory strategies with corporate sustainability goals.

The Role of Integration: Why ERP + APS Is Greater Than the Sum

A standalone APS system is powerful, but when integrated with ERP, it becomes transformational.

With PlanetTogether’s integrations to SAP, Oracle, Microsoft Dynamics, Kinaxis, and Aveva, companies can:

Leverage real-time transactional data for accurate planning

Break down silos between departments and functions

Align supply, production, and demand plans on a single platform

Provide executives with unified dashboards for better strategic oversight

This integration reduces manual handoffs, minimizes data latency, and ensures that supply chain decisions are made on the most up-to-date information — critical for inventory optimization in today’s fast-moving environment.

Winning with Smart Inventory in 2025

For supply chain managers in food and beverage manufacturing, 2025 is not just about cutting costs or speeding up delivery — it’s about achieving a delicate balance.

With the right APS tools, seamlessly integrated with ERP systems, companies can optimize inventory in a way that strengthens resilience, improves efficiency, and supports sustainability goals. PlanetTogether’s advanced planning capabilities, when paired with robust ERP data from SAP, Oracle, Microsoft, Kinaxis, or Aveva, unlock a new level of intelligent, risk-aware inventory management.

By combining these technologies and approaches, F&B manufacturers can confidently navigate today’s uncertainties and position themselves for long-term success.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.