In manufacturing, it is essential to measure the performance of the production facility to evaluate the organization and its success. Key Performance Indicators (KPIs) are often used to do this. KPIs can be defined by a set of quantifiable measures that are used to indicate the performance of the manufacturing operation.

In manufacturing, it is essential to measure the performance of the production facility to evaluate the organization and its success. Key Performance Indicators (KPIs) are often used to do this. KPIs can be defined by a set of quantifiable measures that are used to indicate the performance of the manufacturing operation.

The goal of using KPIs is to understand how well your manufacturing organization is doing and track its performance over time. These help managers understand which areas are in need of improvement and can help set short-term or long-term goals to improve performance. KPIs can also be incorporated into visual management tools for bench-marking and goal-setting.

One important note is that manufacturing organizations must choose KPIs that reflect the goals of the company and can be measured. Not all KPIs are relevant to all industries or organizations.

Choosing the Best KPIs For You

Choosing the best KPI will likely depend on the organization, industry, or even department it will be used in. Using the SMART criteria can help you during this process.

- Is your KPI Specific?

- Can you Measure progress?

- Is the goal Attainable?

- Is it Relevant to the organization?

- What is the Time-frame to achieve the goal?

Using the SMART criteria, you can go from a vague KPI like “Improve Production” to something like “Reduce machine down-time by 10% in the next 3 months”. Then, you will know what to measure (percent of down-time), your goal (10% reduction), and a time-frame (next 3 months).

The following section will cover some common KPIs used in manufacturing and production operations.

Common Manufacturing KPIs

KPIs can vary by department or industry. However, the following examples are commonly used within many manufacturing organizations:

- Downtime - Downtime can be measured as a percentage of the total available time or by the number of hours not spent doing work. This is an important performance indicator to measure as Downtime is costly to manufacturing operations. Reducing the amount of downtime over time is a good indicator that fewer breakdowns or problems are occurring and that there is more time spent producing items.

- Setup Time - Similarly to Downtime, Setup (or changeover) time reflects periods where the resource is unavailable to produce work as it is being configured for the next job. Planners and schedulers may want to generate production schedules that reduce the need to set up to increase production efficiency and profits.

- Production Rate - Generally speaking, the production rate reflects how many units are produced over a certain period. This KPI can be helpful to identify resources that are performing at a slower rate than they should. You can compare actual production rates to target rates and identify whether certain machines need maintenance or if workers need additional training.

- Ratio Rejection - This refers to the number or percentage of items that were rejected due to failure to pass quality standard checks. Depending on the production facility, rejected items may require re-work or be thrown out. Changing production processes and improving the quality of items will help reduce the number of items that are rejected and reduce waste-associated costs.

- Overall Equipment Effectiveness (OEE) - OEE is a formula that calculates how efficient a production facility is based on availability, performance, and quality factors. Manufacturing facilities should aim to have a high OEE percent dictated by a low amount of downtime and waste, and a high production rate.

- Late Orders - Another performance indicator used by many production facilities is the percentage or number of late orders. Late orders can be costly to the manufacturing facility and can negatively impact on the reputation of the company. Organizations should aim to complete shipping all their orders on time.

KPIs are being used by manufacturing operations around the globe and are promoting intuition about productivity awareness and enhancement. Advanced Planning and Scheduling (APS) software such as PlanetTogether APS offers a KPI Pane that allows planners to make informed scheduling decisions.

Utilization of KPIs in Advanced Planning and Scheduling (APS) Software

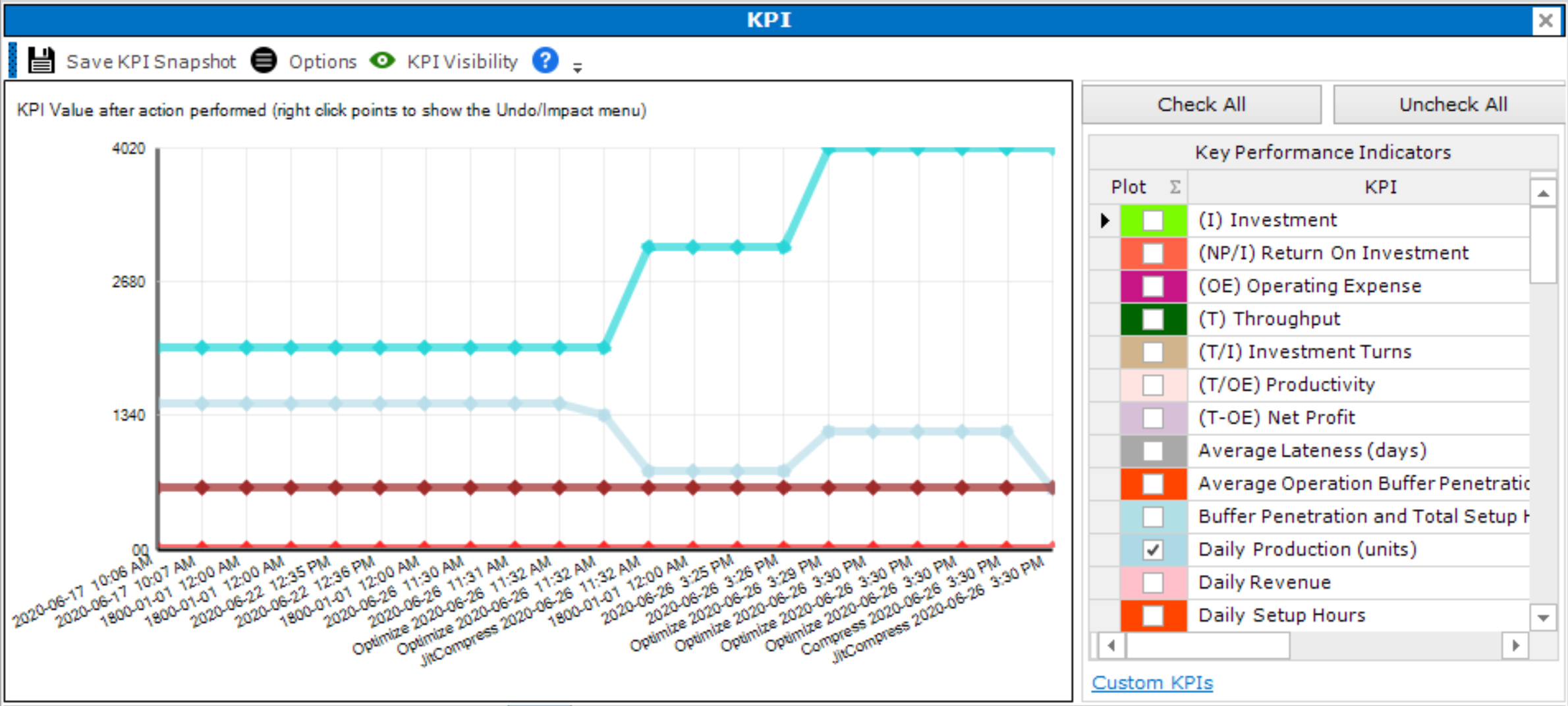

In PlanetTogether, KPIs within a What-If scenario environment can be helpful in determining the most optimal production schedule. This allows planners and schedulers to create multiple iterations of the schedule and see how each change to the schedule affects the relevant KPIs.

A great benefit of the PlanetTogether KPI Pane is that it tracks the KPI values at each schedule iteration. This means that you can easily undo changes to the schedule to return to the version that will give you the best KPI value.

We work with What-If scenarios until we find the schedule that works best for us, then we take it Live.

BRUCE HAYS, DIRECTOR OF MANUFACTURING, J&J SYNTHES

All of these adjustments can be done in a ‘What-If’ environment so that you are confident that you do not disrupt the current Live schedule. Once you are satisfied that you have found the best production schedule to meet your business goals, you can convert it to the Live scenario with the simple click of a button.

Advanced planning and scheduling systems (APS) are compatible with any size manufacturing operation and are a step in the direction of enhancing productivity, accuracy, and overall production efficiency.

PlanetTogether Advanced Planning and Scheduling (APS) Software

Advanced Planning and Scheduling software have become a must for modern-day manufacturing operations as customer demand for increased product assortment, fast delivery, and downward cost pressures become prevalent. These systems help planners save time while providing greater agility in updating ever-changing priorities, production schedules, and inventory plans. APS Systems can be quickly integrated with an ERP/MRP software to fill the gaps where these systems lack planning and scheduling flexibility, accuracy, and efficiency.

With PlanetTogether APS you can:

- Create optimized schedules that balance production efficiency and delivery performance

- Maximize throughput on bottleneck resources to increase revenue

- Synchronize supply with demand to reduce inventories

- Provide company-wide visibility to resource capacity

- Enable scenario data-driven decision making

The implementation of an Advanced Planning and Scheduling (APS) Software will take your manufacturing operations to the next level of production efficiency by taking advantage of the operational data you already possess in your ERP system. APS is a step in the right direction of efficiency and lean manufacturing production enhancement.

Video: Optimizing Production KPIs with What-If Scenarios in PlanetTogether APS

In this video, you’ll see how PlanetTogether Advanced Planning and Scheduling (APS) uses what-if scenarios and a built-in KPI pane to improve production performance. Learn how planners can test schedule changes, compare KPIs like downtime, setup time, OEE, and late orders, and choose the best schedule before going live.

Key takeaways from this video:

- How PlanetTogether APS supports what-if schedule scenarios

- How to use the KPI pane to compare downtime, setup, OEE, and late orders

- How KPI-driven scheduling improves throughput and delivery

- How to safely test changes in a what-if environment before going live

- How APS turns KPI tracking into practical, data-driven decisions

Turn Your KPIs into a Planning and Scheduling Advantage

Tracking KPIs like downtime, setup time, OEE, and late orders is essential—but those numbers only pay off if they change how you plan and schedule production. When schedules still live in spreadsheets, it’s hard to see which decisions actually improve KPIs and which quietly increase waste, lateness, and costs.

Download our one-page “The Money Is in the Planning” infographic to quickly see how planning and scheduling decisions show up in your KPIs as:

- Higher or lower downtime, setup time, and rejection rates

- Better or worse OEE, throughput, and resource utilization

- More or fewer late orders and broken promise dates

- Inventory and WIP that either support or undermine your goals

Use it as a quick checklist with your team to connect the KPIs you track with the planning and scheduling changes that will actually move those numbers in the right direction—especially when you’re using APS and what-if scenarios to refine your schedule.