There is much to consider when it pertains to ordering raw materials. Cost, transportation, and inventory are just a few of the various aspects of raw material purchasing and ordering, which plays a vital role within the production process. This is where one of the most important aspects of the supply chain comes into play - materials management.  Without materials management, raw materials are not easily able to adjust to a changing demand and product order fulfillment. This is how your manufacturing operation can adequately order parts and optimize overall production. To effectively optimize production, you must look at the 5 crucial processes and people within materials management.

Without materials management, raw materials are not easily able to adjust to a changing demand and product order fulfillment. This is how your manufacturing operation can adequately order parts and optimize overall production. To effectively optimize production, you must look at the 5 crucial processes and people within materials management.

5 Crucial Components - Process and People

Preparing the best team for production is the only way to take your operation to the next level. Experienced and skilled materials managers know how to properly execute the following components:

- Leadership - Adequately managing a skillful and diverse team.

- Materials Procurement - Utilization of domestic and low cost country sourcing.

- Strategic Cost Execution - Effectively managing cost within the supply chain.

- Overseeing Materials - Overseeing the entire materials management process, internal and external.

- Decision Making - Choosing the best forms of produce sourcing methods, ensuring for a smooth and steady flow of goods.

Along with these processes, there are various people within the process that play key roles:

- Vendor Partners - Partners that are familiar with your production process and choose quality raw materials.

- Directors of Transportation - Transportation directors that utilize the most efficient and cost-friendly transportation methods.

- Production Managers - Managers that oversee the entire production process, from raw materials to the finished product.

- Procurement Managers - Accounting for a varying demand and obtaining quality goods and services.

- Sourcing Consultants - Finding the most favorable vendors and suppliers for your supply chain.

These 5 processes and people within the materials management process are extremely advantageous to the manufacturing process and will ultimately cut cost and bring in more revenue. Although materials management is a vital component to the supply chain, advanced planning and scheduling software can build upon the process.

Advanced Planning and Scheduling Software with Materials Management

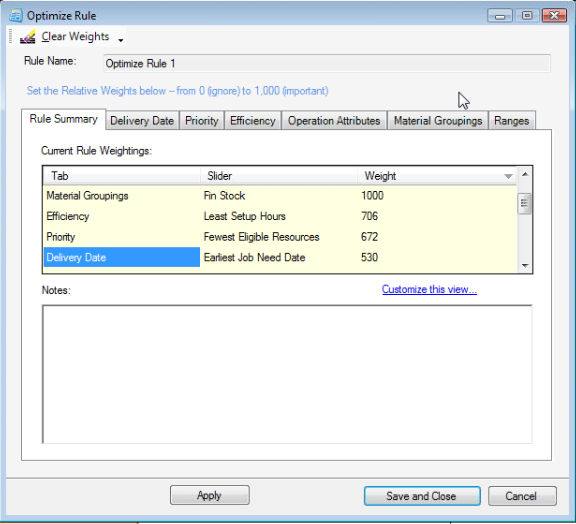

Advanced planning and scheduling software (APS) is becoming a top choice for manufacturers. As manufacturers are finding out that ERP and MRP systems alone are not enough, APS offers as an extension to those systems and offers various benefits and capabilities. Some of the benefits of advanced planning and scheduling software (APS) includes the following:

If you’re juggling vendors, transport, procurement, and production but still fighting stockouts, rush orders, and late shipments, you’re not alone. Strong materials management is essential—but ERP and spreadsheets can only take you so far.

Discover how advanced planning and scheduling (APS) works alongside ERP to connect materials, capacity, and demand in one realistic plan you can actually execute. Download our free white paper, “Why ERP Alone Is Not the Answer,” and see how leading manufacturers are improving delivery performance, cutting inventory and labor costs, and achieving ROI in as little as six months.

Related Capacity Planning Video

APS Resources