Topics: Advanced Planning and Scheduling, master production scheduling, Production Scheduling Software, production planning software

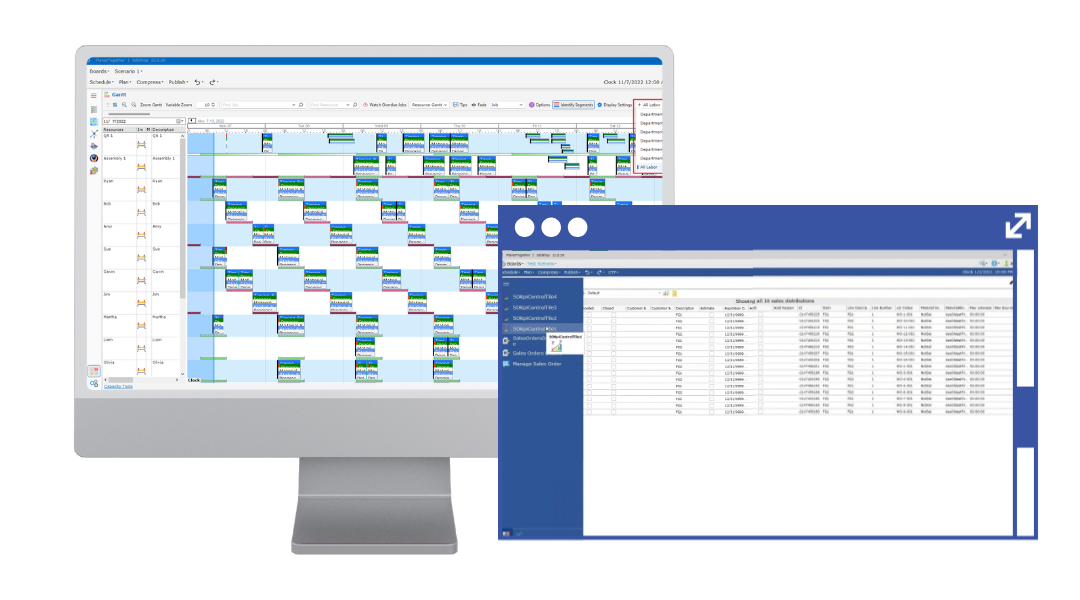

Advanced Planning and Scheduling (APS) and Master Production Scheduling (MPS) are two key components of the broader field of production planning and control. These concepts play crucial roles in optimizing manufacturing processes and ensuring efficient utilization of resources.

While both Master Production Scheduling (MPS) and Advanced Planning and Scheduling (APS) are related concepts within the field of manufacturing, they are not exactly the same.

MPS is a detailed plan that specifies the production schedule for each finished product over a specific time horizon. It translates the overall production plan into specific quantities of individual end products by considering factors like customer demand, inventory levels, and production capacity.

APS is a more comprehensive and sophisticated approach to production planning. It involves the use of advanced algorithms and computer-based systems to optimize various aspects of the production process, including scheduling, resource allocation, and demand forecasting.

Master Production Scheduling is a specific step within the production planning process, while Advanced Planning and Scheduling refers to a more comprehensive set of tools and methodologies that aim to improve the efficiency and effectiveness of the entire production planning and scheduling process.

it is clear that Advanced Planning and Scheduling not only complements but surpasses traditional approaches. With APS at the helm, manufacturers can confidently navigate the challenges of the future, ensuring not just the meeting but the surpassing of customer expectations. In the realm of MPS and APS, it is the comprehensive capabilities of the latter that elevate manufacturing into a new era of excellence.

Topics: Advanced Planning and Scheduling, master production scheduling, Production Scheduling Software, production planning software

0 Comments

No video selected

Select a video type in the sidebar.

LEAVE A COMMENT