Cloud-Based Product Lifecycle Management Solutions

In packaging manufacturing, where every minute counts and every resource is precious, the role of a Production Planner is essential. With the constant pressure to optimize processes, reduce costs, and meet ever-changing consumer demands, production planners are constantly seeking innovative solutions to streamline operations and enhance efficiency.

One such solution that has been revolutionizing the industry is cloud-based Product Lifecycle Management (PLM) software.

In this blog, we will look into the significance of cloud-based PLM solutions for packaging manufacturing, focusing on the integration between PlanetTogether and leading ERP, SCM, and MES systems such as SAP, Oracle, Microsoft, Kinaxis, Aveva, and others.

Cloud-Based PLM Solutions

Traditional PLM systems have long been integral to the manufacturing process, enabling companies to manage product data, streamline workflows, and collaborate across teams. However, the emergence of cloud technology has taken PLM to new heights, offering scalability, flexibility, and accessibility like never before.

Cloud-based PLM solutions empower packaging manufacturers to centralize product information, automate processes, and facilitate real-time collaboration among stakeholders, regardless of geographical location. By leveraging the power of the cloud, companies can overcome the limitations of on-premises systems, such as infrastructure costs, scalability constraints, and data silos.

Integration with ERP, SCM, and MES Systems

One of the key advantages of cloud-based PLM solutions is their seamless integration with Enterprise Resource Planning (ERP), Supply Chain Management (SCM), and Manufacturing Execution Systems (MES). This integration enables packaging manufacturers to achieve end-to-end visibility and control over the entire product lifecycle, from ideation to delivery.

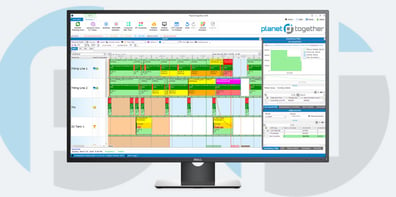

PlanetTogether, a leading production planning software, plays a crucial role in this integration ecosystem. By integrating with top-tier ERP systems such as SAP, Oracle, Microsoft Dynamics, Kinaxis RapidResponse, Aveva, and others, PlanetTogether enables production planners to synchronize production schedules with inventory levels, demand forecasts, and resource availability in real-time.

Benefits of Integration

The integration between PlanetTogether and ERP, SCM, and MES systems offers a myriad of benefits for production planners in packaging manufacturing facilities:

Enhanced Visibility: By consolidating data from multiple systems into a single platform, production planners gain comprehensive visibility into all aspects of the manufacturing process. This allows them to make informed decisions, identify bottlenecks, and optimize resource allocation for maximum efficiency.

Improved Collaboration: Cloud-based PLM solutions facilitate seamless collaboration across departments, enabling production planners to work closely with sales, procurement, engineering, and other teams to align objectives and drive innovation.

Agile Decision-Making: With real-time access to accurate data, production planners can respond quickly to changing market dynamics, customer demands, and supply chain disruptions. This agility is crucial for staying competitive in today's dynamic business landscape.

Optimal Resource Utilization: By integrating production planning with ERP, SCM, and MES systems, companies can optimize resource utilization, minimize waste, and reduce lead times. This leads to cost savings and improved profitability.

Cloud-based PLM solutions are transforming the packaging manufacturing industry by offering unprecedented scalability, flexibility, and integration capabilities. By leveraging platforms like PlanetTogether and integrating them with leading ERP, SCM, and MES systems, production planners can streamline operations, enhance collaboration, and drive innovation.

As we navigate the future of packaging manufacturing, embracing cloud-based PLM solutions will be key to staying ahead of the curve and meeting the evolving needs of consumers and markets alike. With the right tools and strategies in place, production planners can unlock new opportunities for growth, efficiency, and sustainability in the dynamic world of packaging manufacturing.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.