Digital Transformation: The Impact on Scheduling Processes

Production schedulers play a crucial role in ensuring that the manufacturing process runs smoothly, meeting demand while maintaining quality standards in pharmaceutical manufacturing. However, the landscape of manufacturing is rapidly evolving with the advent of digital transformation.

In this blog, we'll explore the profound impact of digital transformation on scheduling processes in pharmaceutical manufacturing facilities. Specifically, we'll look into the integration between PlanetTogether, a leading production scheduling software, and various ERP, SCM, and MES systems like SAP, Oracle, Microsoft, Kinaxis, and Aveva, highlighting the benefits and challenges of this integration.

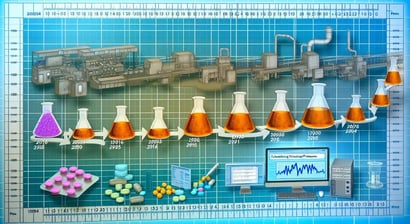

The Evolution of Scheduling Processes

Traditionally, scheduling in pharmaceutical manufacturing relied heavily on manual processes and spreadsheets. This approach was not only time-consuming but also prone to errors, leading to inefficiencies and disruptions in production. However, with the emergence of digital technologies, there has been a paradigm shift in scheduling processes.

Digital transformation has paved the way for advanced scheduling software like PlanetTogether, which leverages artificial intelligence and optimization algorithms to create efficient production schedules. These software solutions take into account various factors such as production capacity, resource availability, and demand forecasts to generate optimal schedules in a fraction of the time it would take manually.

Integration with ERP, SCM, and MES Systems

One of the key aspects of digital transformation in scheduling processes is the integration between production scheduling software like PlanetTogether and enterprise resource planning (ERP), supply chain management (SCM), and manufacturing execution systems (MES). This integration allows for seamless data exchange and synchronization between different systems, streamlining the entire manufacturing process.

For instance, integration with ERP systems such as SAP, Oracle, or Microsoft Dynamics enables production schedulers to access real-time information on inventory levels, material availability, and customer orders. This visibility allows them to make informed decisions when creating schedules, ensuring that production aligns with demand and inventory levels are optimized.

Similarly, integration with SCM systems like Kinaxis facilitates collaboration with suppliers and enables proactive management of the supply chain. By integrating with MES systems such as Aveva, production schedulers can monitor and control the execution of manufacturing processes in real-time, ensuring that schedules are adhered to and any deviations are promptly addressed.

Benefits of Integration

The integration between PlanetTogether and ERP, SCM, and MES systems offers a myriad of benefits for pharmaceutical manufacturing facilities:

Improved Efficiency: By automating scheduling processes and integrating with other systems, production schedulers can create more efficient schedules, minimizing idle time and maximizing resource utilization.

Enhanced Visibility: Real-time data synchronization provides production schedulers with visibility into every aspect of the manufacturing process, enabling them to identify bottlenecks and address them proactively.

Increased Agility: With integrated systems, production schedulers can quickly adjust schedules in response to changes in demand, supply constraints, or production disruptions, ensuring that production remains agile and responsive.

Better Decision-Making: Access to accurate and up-to-date information enables production schedulers to make informed decisions, optimizing production schedules to meet customer demands while minimizing costs.

Challenges and Considerations

While the integration between production scheduling software and ERP, SCM, and MES systems offers significant benefits, it also comes with its challenges and considerations:

Integration Complexity: Integrating multiple systems with different architectures and data formats can be complex and time-consuming, requiring careful planning and coordination.

Data Accuracy and Consistency: Ensuring the accuracy and consistency of data across integrated systems is essential to avoid discrepancies and errors that could impact production schedules.

Change Management: Adopting new scheduling processes and integrated systems may require changes to existing workflows and employee training, necessitating effective change management strategies.

Security and Compliance: Protecting sensitive data and ensuring compliance with regulatory requirements such as Good Manufacturing Practices (GMP) and data privacy regulations is crucial when integrating systems.

Digital transformation is reshaping scheduling processes in pharmaceutical manufacturing, enabling production schedulers to create more efficient, agile, and responsive schedules. The integration between production scheduling software like PlanetTogether and ERP, SCM, and MES systems plays a pivotal role in this transformation, offering benefits such as improved efficiency, enhanced visibility, increased agility, and better decision-making.

While challenges exist, careful planning, implementation, and ongoing management can help pharmaceutical manufacturing facilities navigate the complexities of digital transformation and unlock the full potential of integrated scheduling processes.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.