Driving Next-Gen Efficiency: How Digital Technology Integration Transforms Supply Chain Management in Industrial Manufacturing

In industrial manufacturing, maintaining a competitive edge means more than just controlling costs and streamlining operations. It requires reimagining how technologies are integrated across the supply chain to enhance agility, visibility, and responsiveness. For Supply Chain Managers, digital technology integration is no longer a future aspiration—it’s a current imperative.

From IoT sensors and AI-driven forecasting to cloud-based Advanced Planning and Scheduling (APS) systems like PlanetTogether, the modern supply chain thrives on interconnected systems. But unlocking their full value often depends on seamless integration with enterprise platforms such as SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva. Together, these systems form the foundation of intelligent decision-making, predictive planning, and real-time responsiveness.

This blog explores the transformative role of digital integration in industrial manufacturing supply chains—and how strategic convergence of PlanetTogether with ERP/MES platforms empowers leaders to achieve more with less.

The Digital Supply Chain Imperative

Digital technology has redefined how supply chains operate. Traditional, siloed operations no longer suffice in an environment where demand shifts rapidly, lead times fluctuate, and customer expectations are higher than ever. In response, industrial manufacturers are evolving toward digitally unified supply chains.

Key drivers for this shift include:

Increased demand volatility

Globalized supplier networks

Rising expectations for transparency and traceability

Sustainability and regulatory compliance pressures

Operational efficiency mandates

A fragmented approach—where data lives in different systems that don’t communicate—creates blind spots. Supply Chain Managers must pivot from reactive firefighting to proactive orchestration, leveraging integrated technologies to improve visibility, automate workflows, and enable data-driven decisions.

Integration in Action: PlanetTogether and ERP/MES Platforms

At the heart of digital transformation is integration—bringing systems together to share data, insights, and workflows in real time.

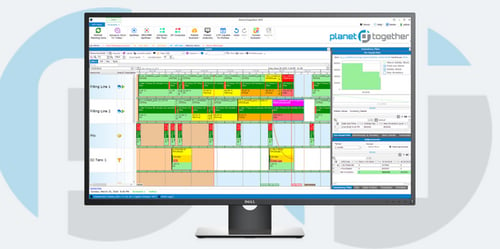

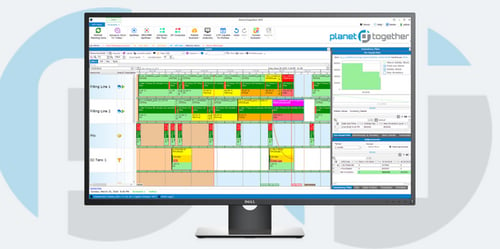

PlanetTogether’s Advanced Planning and Scheduling (APS) platform is purpose-built to optimize production schedules, resource allocation, and inventory management. But its true power is unlocked when integrated with ERP platforms like:

SAP – for end-to-end order management, procurement, and production execution

Oracle – to unify financial, procurement, and logistics data into a single planning model

Microsoft Dynamics – to bridge planning and operations with intuitive interfaces and reporting

Kinaxis – to provide scenario modeling, rapid response to supply chain disruptions, and demand alignment

Aveva – to fuse real-time plant operations with forward-looking supply planning

When PlanetTogether integrates with these systems, it creates a closed-loop supply chain. This enables synchronized planning and execution—where changes in orders, material availability, or capacity automatically cascade through the system.

Key Benefits of Digital Technology Integration for Supply Chain Managers

End-to-End Visibility and Real-Time Insights

Integration eliminates data silos, providing Supply Chain Managers with a centralized, real-time view of demand, inventory, supplier performance, and production status. With PlanetTogether feeding and receiving data from ERP systems, planners can:

Track order progression from customer request to shipment

Visualize production constraints and adapt schedules proactively

Identify bottlenecks before they disrupt downstream activities

This 360-degree visibility accelerates decision-making and improves responsiveness across the value chain.

Scenario Planning and Predictive Capabilities

One of the most powerful benefits of digital integration is the ability to run what-if scenarios. For example:

What happens if a supplier shipment is delayed by two days?

How will an unexpected surge in demand impact delivery dates?

Can production resources handle a new product introduction?

PlanetTogether’s scenario planning tools, combined with the forecasting strength of systems like Kinaxis or Oracle, allow Supply Chain Managers to evaluate outcomes instantly and adjust plans accordingly—before issues affect customers.

Optimized Resource Utilization and Cost Efficiency

In industrial manufacturing, resource utilization is critical. Through integration, APS tools can tap into ERP data to dynamically allocate labor, machinery, and materials for maximum throughput and minimal waste. For instance:

PlanetTogether can optimize production runs based on SAP’s material availability and batch constraints

It can synchronize with Aveva’s real-time equipment status to avoid downtime

Microsoft Dynamics can feed in financial data to align schedules with cost optimization targets

These capabilities help balance efficiency and cost, enabling leaner, more agile operations.

Agility and Resilience in Uncertain Environments

From geopolitical disruptions to raw material shortages, uncertainty is the new normal. Integrated digital systems empower supply chains to:

Rapidly respond to disruptions by reconfiguring supply routes and production plans

Trigger automated alerts and workflows across departments

Ensure compliance and traceability by logging decisions across interconnected systems

This agility is particularly crucial in industrial manufacturing, where supply chain inertia can lead to costly idle time and lost revenue.

Collaboration Across Functions and Partners

True digital integration extends beyond the four walls of the factory. ERP-connected APS systems foster collaboration by:

Providing a unified platform for procurement, logistics, production, and sales teams

Enabling suppliers to access real-time demand signals and capacity constraints

Aligning manufacturing and financial goals through synchronized planning

This fosters a more collaborative supply chain ecosystem that supports shared goals and accountability.

Digital technology integration is no longer optional—it’s foundational to effective supply chain management in industrial manufacturing. Supply Chain Managers who embrace platforms like PlanetTogether, integrated with systems such as SAP, Oracle, Microsoft, Kinaxis, or Aveva, gain the clarity, agility, and control needed to thrive in today’s dynamic markets.

From predictive scheduling to real-time collaboration, digital integration delivers the tools to navigate uncertainty, reduce inefficiencies, and drive strategic value. In short, it transforms the supply chain from a cost center into a competitive advantage.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.