Embracing Automation While Maintaining Strict Cybersecurity in Industrial Manufacturing

The industrial manufacturing landscape is in the midst of a transformation—one driven by automation, data integration, and smart factory technologies. As production floors become more connected, Plant Managers are challenged with balancing the promise of efficiency and performance with the growing threat of cyberattacks.

Automation is no longer a luxury—it's essential for survival in a highly competitive and rapidly digitizing market. Yet, every sensor added, robot integrated, and AI-driven decision made is a potential entry point for cybersecurity vulnerabilities. For Plant Managers tasked with optimizing throughput while safeguarding operational technology (OT), embracing automation must go hand-in-hand with maintaining airtight cybersecurity.

This blog explores how Plant Managers in industrial manufacturing can safely embrace automation by integrating PlanetTogether Advanced Planning and Scheduling (APS) with enterprise systems such as SAP, Oracle, Microsoft, Kinaxis, or Aveva, all while establishing robust cybersecurity protocols.

The Drive Toward Automation in Industrial Manufacturing

Industrial manufacturing facilities are accelerating automation to address a multitude of operational goals, including:

Reducing human error and labor costs

Increasing throughput and machine utilization

Improving predictive maintenance and reducing unplanned downtime

Enhancing agility in response to demand shifts or supply disruptions

Automation systems today extend beyond the factory floor. Cloud-based scheduling, IoT-enabled monitoring, and AI-powered production optimization tools, such as PlanetTogether APS, are integrated into enterprise ecosystems. These tools connect ERP systems (like SAP and Oracle), MES platforms, and edge devices in real time—creating a seamless flow of operational data across the plant.

However, this hyperconnectivity introduces complex cybersecurity risks.

Cybersecurity Risks: Why Automation Raises the Stakes

As Plant Managers deploy automation, they must be keenly aware of the potential for increased exposure to cyber threats. Common vulnerabilities include:

Unsecured communication protocols between machines and control systems

Legacy systems that lack modern security updates or support

Third-party software integrations without strong access controls

Increased attack surface due to cloud connectivity and remote access

A successful attack on an industrial manufacturing facility could halt production, corrupt product data, damage machinery, or even jeopardize worker safety. According to a recent IBM report, manufacturing became the most targeted industry for cyberattacks in 2023, overtaking financial services.

The Role of PlanetTogether APS in Secure Automation

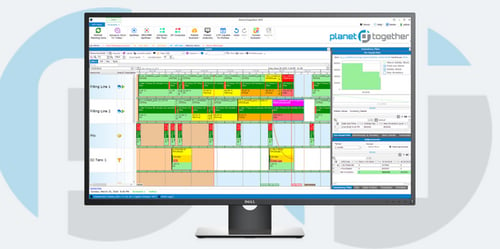

PlanetTogether APS offers a centralized planning and scheduling platform that helps manufacturers optimize production schedules in real time. But just as importantly, it can be securely integrated into broader enterprise IT and OT infrastructures when aligned with robust cybersecurity standards.

Integration with leading systems such as:

SAP (for enterprise resource management)

Oracle (for supply chain and financial operations)

Microsoft (for cloud infrastructure and business intelligence)

Kinaxis (for real-time supply chain visibility)

Aveva (for manufacturing execution and industrial data visualization)

enables cross-functional visibility while allowing cybersecurity teams to enforce identity management, data encryption, access control, and network segmentation policies.

By operating within these enterprise ecosystems, PlanetTogether benefits from the cybersecurity protocols already in place—such as SAP's secure authentication models or Microsoft's zero-trust architecture—while also adding its own layers of protection at the scheduling level.

Building a Secure Automation Framework: 6 Pillars for Plant Managers

To ensure secure automation, Plant Managers should lead initiatives built on the following pillars:

Zero Trust Security Model

Adopt a “never trust, always verify” stance, even for internal communications between systems. Require authentication for every device, application, and user accessing automation or scheduling tools.

Example: When integrating PlanetTogether with Microsoft Azure, configure role-based access control (RBAC) and multi-factor authentication for all users interacting with production data.

Network Segmentation

Separate IT networks (corporate systems) from OT networks (plant operations). This limits lateral movement in the event of a breach and protects production assets.

Actionable Tip: Place PlanetTogether APS in a “demilitarized zone” (DMZ) that bridges both IT and OT environments, with firewall rules controlling data exchange with ERP systems like Oracle or SAP.

Regular Patching and Updates

Automation and scheduling tools must be routinely patched to prevent known vulnerabilities from being exploited.

Best Practice: Ensure that PlanetTogether APS and its connectors to Aveva or Kinaxis are kept current with security updates and vendor-recommended configurations.

Encrypted Data Transfer

Secure all data-in-transit and data-at-rest using industry-standard encryption protocols. This is critical when production data is flowing between scheduling tools and cloud-hosted ERP systems.

Tip for SAP Integration: Use Transport Layer Security (TLS) and secure tunneling protocols to protect communication between PlanetTogether and SAP HANA databases.

Incident Response Planning

Have a clear cybersecurity incident response plan that includes automation systems. Know how to isolate equipment, disable access, and recover data without crippling production.

Pro Tip: Simulate a ransomware attack on your integrated APS-ERP environment and conduct tabletop exercises with IT and OT teams.

Employee Training and Awareness

Your automation systems are only as secure as the people operating them. Conduct regular training on phishing attacks, secure credentials, and digital hygiene.

Recommendation: Include scheduler and planning personnel in cybersecurity workshops. Help them understand how secure usage of APS platforms like PlanetTogether affects broader plant security.

Benefits of Secure Automation for Plant Managers

By embracing automation through secure platforms and protocols, Plant Managers can unlock substantial benefits:

Improved operational efficiency with real-time, optimized scheduling

Faster decision-making from integrated ERP, APS, and MES systems

Reduced downtime due to predictive analytics and process transparency

Stronger compliance posture with industry regulations like ISO/IEC 62443

Greater workforce trust in technology that empowers—not endangers—them

Secure automation isn't just a defensive strategy—it's a competitive advantage that positions your plant as a future-ready facility capable of scaling and adapting with confidence.

As automation continues to reshape industrial manufacturing, Plant Managers must take the lead in aligning innovation with security. Platforms like PlanetTogether APS, when integrated securely with ERP and MES systems from SAP, Oracle, Microsoft, Kinaxis, or Aveva, provide the foundation for intelligent, secure production environments.

Cybersecurity is not a barrier to automation—it is the enabler. By embedding security into every step of your automation journey, you ensure that your plant operates not just efficiently, but resiliently.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.