Enhancing Supply Chain Agility in Medical Manufacturing for Rapid Response

In today's dynamic market, the ability to respond swiftly to changes is crucial for the success of any manufacturing facility, particularly in the medical industry where precision and timeliness are paramount. As a Supply Chain Manager in a medical manufacturing facility, you're constantly challenged to adapt to evolving market demands, regulatory requirements, and unexpected disruptions. In such an environment, embracing agile manufacturing methodologies becomes imperative to stay competitive and meet customer expectations.

Agile manufacturing is not merely a buzzword; it's a strategic approach that enables companies to respond rapidly and efficiently to fluctuations in demand, changes in product specifications, or disruptions in the supply chain. At the heart of agile manufacturing lies the seamless integration of various systems and processes, enabling real-time visibility, collaboration, and decision-making.

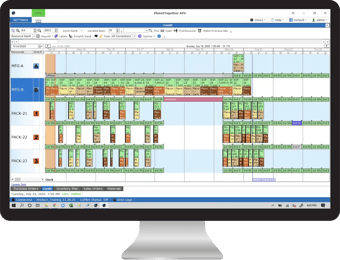

One of the key players in the realm of agile manufacturing solutions is PlanetTogether, a powerful production planning and scheduling software. When combined with robust Enterprise Resource Planning (ERP), Supply Chain Management (SCM), and Manufacturing Execution Systems (MES), it creates a formidable arsenal for achieving operational excellence and rapid response capabilities.

Agile Manufacturing

Before looking into the integration aspect, let's briefly revisit the core principles of agile manufacturing:

Flexibility: Agile manufacturing emphasizes the ability to adapt quickly to changes without compromising quality or efficiency. This involves flexible production processes, agile supply chains, and versatile workforce capabilities.

Visibility: Real-time visibility across the entire manufacturing ecosystem is essential for identifying bottlenecks, optimizing resources, and making informed decisions promptly.

Collaboration: Agile manufacturing thrives on collaboration among different departments, suppliers, and even customers. Seamless communication channels facilitate quicker problem-solving and innovation.

Continuous Improvement: The pursuit of excellence is perpetual in agile manufacturing. Continuous improvement initiatives such as Lean manufacturing and Six Sigma help streamline processes, eliminate waste, and enhance overall efficiency.

Challenges in Achieving Agile Manufacturing

While the benefits of agile manufacturing are undeniable, implementing and sustaining it pose several challenges, especially in complex environments like medical manufacturing. Some common hurdles include:

Data Silos: Disparate systems often result in data silos, hindering real-time collaboration and decision-making.

Complexity: Integrating multiple systems with varying functionalities and architectures can be daunting and resource-intensive.

Legacy Systems: Many manufacturing facilities still rely on legacy systems that may not be compatible with modern agile methodologies.

Regulatory Compliance: Stringent regulatory requirements in the medical industry add another layer of complexity, necessitating meticulous documentation and adherence to standards.

Integration: Unlocking the Power of Agile Manufacturing

The integration of PlanetTogether with leading ERP, SCM, and MES systems offers a holistic solution to overcome the challenges mentioned above and unleash the full potential of agile manufacturing. Let's explore how this integration enhances key aspects of agile manufacturing:

Real-Time Data Synchronization: Integration ensures seamless data flow between different systems, providing real-time visibility into inventory levels, production schedules, and demand forecasts. This enables accurate decision-making and proactive response to changes in market demand or supply chain disruptions.

End-to-End Visibility: By integrating PlanetTogether with ERP, SCM, and MES systems, Supply Chain Managers gain comprehensive visibility across the entire value chain, from procurement and production to distribution and customer service. This visibility allows for better resource allocation, optimized inventory management, and faster order fulfillment.

Streamlined Planning and Scheduling: PlanetTogether's advanced planning and scheduling capabilities, when integrated with ERP and MES systems, facilitate optimized production plans based on real-time demand forecasts, resource availability, and capacity constraints. This ensures efficient utilization of resources and minimizes production lead times.

Improved Collaboration: Integration fosters seamless collaboration among different departments, suppliers, and partners. By sharing critical information such as production schedules, inventory levels, and quality data in real-time, teams can coordinate effectively, address issues proactively, and drive continuous improvement initiatives.

Compliance and Traceability: In the highly regulated medical industry, compliance with quality standards and traceability requirements is non-negotiable. Integration between PlanetTogether and MES systems enables automated data capture, process monitoring, and documentation, ensuring compliance with regulatory mandates and facilitating faster audits and recalls.

Choosing the Right Integration Approach

Integrating PlanetTogether with ERP, SCM, and MES systems requires careful planning and consideration of various factors, including:

System Compatibility: Ensure compatibility between different systems and evaluate the need for customizations or middleware solutions to bridge any gaps.

Data Mapping and Transformation: Define clear data mapping rules and transformation processes to ensure consistency and accuracy across integrated systems.

Security and Data Privacy: Implement robust security measures to safeguard sensitive data and comply with data privacy regulations such as GDPR and HIPAA.

Scalability and Future-Proofing: Choose integration solutions that are scalable and adaptable to future business needs, allowing for seamless expansion or integration with additional systems.

Agile manufacturing is not just a theoretical concept but a practical necessity for modern medical manufacturing facilities striving to stay competitive in today's dynamic market landscape. By integrating PlanetTogether with ERP, SCM, and MES systems, Supply Chain Managers can unlock the full potential of agile manufacturing, enabling rapid response to market changes, optimizing resource utilization, and ensuring compliance with regulatory requirements.

Embrace agile manufacturing today to future-proof your operations and drive sustainable growth in the ever-evolving medical industry. Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.